|

| Author |

Message |

DaveBell

Moderator

|

# Posted: 6 Jan 2017 08:13am

Reply Quote

It's my understanding that the power coming into your cabin or house (modern/new) is

one black wire 120V Phase A,

one black wire 120V Phase B,

one white wire neutral/return to a bus bar, and

one green ground wire to a ground bus bar.

240V circuits are connected to a double circuit breaker, one wire to the 120V Phase A, one wire to the 120V Phase B. No neutral/return needed because the two phases are 180 degrees out of phase with each other.

Why are 240V motors called single phase when they are connected to two phases of power?

|

|

toyota_mdt_tech

Member

|

# Posted: 6 Jan 2017 10:27am - Edited by: toyota_mdt_tech

Reply Quote

If you measure from phase to phase, its 240 VAC. Usually, service in line, line and neutral. You install the ground rod at the primary panel and bond it to neutral. Any panels after primary, ie secondary is 4 wires, ie line line neutral and then a 4th ground wire. The ground wire can be smaller diameter (gauge)

A 240V clothes dryer plugs into 220/240 but its set up with one side running the 110V motor and other leg running the heating element. A 240VAC motor will use 240VAC.

If your motor has single phase, it will have 2 poles, ie north and south if its a 3600 rpm motor (induction type) and if its an 1800 rpm (loaded it 1725) then it will have 4 poles.

I don't think there is any such thing as a 2 phase motor?

3 phase will have 6 poles for 3600 rpm, but they do not have any start or run winding's, just all one set of winding's. This eliminates centrifugal switches, motor start and run capacitors etc. Usually 3 phase motors are cheaper too.

|

|

toyota_mdt_tech

Member

|

# Posted: 6 Jan 2017 10:29am

Reply Quote

The power company stator that produces the power is wires as a "WYE" and there is the 3 legs and a common tie point in the middle. So it would make sense the voltage from a 220 system will be 110 from WYE middle to each leg, but from leg to leg, 220 volts. The phases are synched so a 2 phase wouldn't work unless the generator was wired 2 phase (at power plant) or something done electronically (spendy)

|

|

sparky30_06

Member

|

# Posted: 6 Jan 2017 11:06am

Reply Quote

Single phase power can be 120 or 240. Some what of a generic term. Now if you really want to toss a wrench in the 3 phase world add in the "delta" transformer

|

|

drb777

Member

|

# Posted: 6 Jan 2017 01:51pm - Edited by: drb777

Reply Quote

My cabin location is served by a rural electric co-op, and provides only single phase service. Since my overhead service pole spot is some 1500 feet away from my property, I had them install a 480 volt transformer/meter to provide me adequate amperage without requiring an excessive wire size (and very high wire cost). So much of my underground distribution system is #6 and #8 copper, and 4/1 a step-down transformer at the cabin end.

Every rural situation is different, and existing infrastructure can certainly be limited. Fortunately most of our power requirements are relatively small. With a bit of thought and planning, nearly everyone can be connected, if desired.

On the other hand, remote, high power 3 phase needs (mostly industrial) can be quite a challenge and very expensive.

|

|

DaveBell

Moderator

|

# Posted: 6 Jan 2017 02:42pm

Reply Quote

Quoting: DaveBell Why are 240V motors called single phase when they are connected to two phases of power?

I just found it. I've been banging my head on the keyboard trying to figure this out for about a week.

Because an o-scope between L1 and L2 (240V) will show a single phase alternating between the two. An O-scope with two channels looking at L1 (120V) to neutral and L2 (120V) to neutral will show L1 and L2 180 degrees out of phase.

So it is both less filling and tastes great.

|

|

bldginsp

Member

|

# Posted: 6 Jan 2017 04:16pm

Reply Quote

Quoting: DaveBell Why are 240V motors called single phase when they are connected to two phases of power?

They are two legs of one phase. One phase across two legs.

If you add a third leg, phases are possible across three combinations of legs.

So, one and one make one, but add another and you have three. So, in this case, one and one make three.

Or, as Jelly Roll Morton said, two and two make three.

|

|

Cowracer

Member

|

# Posted: 6 Jan 2017 05:17pm - Edited by: Cowracer

Reply Quote

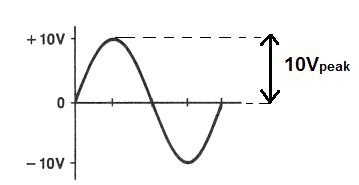

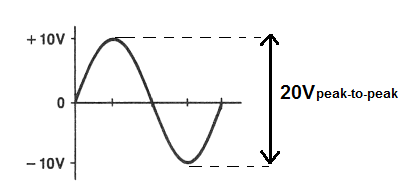

110 and 220 are both single phase. One (110v) just uses half the wave form from 0v to peak:

220v uses the whole wave from peak-to-peak.

Its the exact same single phase wave, its just in how you use it.

Tim

|

|

|

Cowracer

Member

|

# Posted: 6 Jan 2017 05:22pm

Reply Quote

Quoting: toyota_mdt_tech 3 phase will have 6 poles for 3600 rpm,

Slight error Toyota... a 3600 rpm 60hz motor will only have 2 poles. Speed decreases as # of poles goes up. a 6 pole motor would only run 1200rpm.

Tim

|

|

toyota_mdt_tech

Member

|

# Posted: 6 Jan 2017 10:11pm - Edited by: toyota_mdt_tech

Reply Quote

Quoting: Cowracer Slight error Toyota... a 3600 rpm 60hz motor will only have 2 poles. Speed decreases as # of poles goes up. a 6 pole motor would only run 1200rpm. Tim

Tim, for a 3 phase? I was speaking 3 phase only in the quoted text.

A 3 phase motor needs multiples of 3 doesnt it? IE a WYE wound stator would have 3 poles for 3600 rpm

|

|

Cowracer

Member

|

# Posted: 6 Jan 2017 10:51pm - Edited by: Cowracer

Reply Quote

Yep. First off, you must always have an even number of poles. 2,4,6 etc. You cannot have a odd number of poles. Understand that when they say 2 pole, they mean 2 poles per phase. In actuality a 2 pole, 3 phase motor actually has 6 individual poles (a north and south for each phase), but its considered a 2 pole motor.

You have to have an even number of poles because every magnet has to have a north and south pole. You cant have one without the other.

The formula for synchronous speed of an induction motor is:

(120*frequency) ÷ poles or with a US standard freq of 60hz

(120*60) ÷ poles

As you can see, number of poles decreases speed. It makes no difference if its wired delta or wye.

Tim

|

|

toyota_mdt_tech

Member

|

# Posted: 7 Jan 2017 09:32am

Reply Quote

Quoting: Cowracer 3 phase motor actually has 6 individual poles (a north and south for each phase), but its considered a 2 pole motor.

Thanks cowracer, I was aware of that, but not on the terminology, so your reply confused me. OK, we are on the same page then.

Great info too I might add.

|

|

Cowracer

Member

|

# Posted: 7 Jan 2017 01:04pm

Reply Quote

Quoting: toyota_mdt_tech Great info too I might add.

Inside every engineer is a frustrated teacher just dying to get out. LOL

Tim

|

|

toyota_mdt_tech

Member

|

# Posted: 7 Jan 2017 05:03pm

Reply Quote

Quoting: Cowracer Inside every engineer is a frustrated teacher just dying to get out. LOL Tim

We all appreciate it. This entire group is loaded with very informed, well educated, highly skilled, master craftsman or a combination of some or all of the above. All have great info they contribute to the forum.

|

|

low277

Member

|

# Posted: 8 Jan 2017 09:06pm

Reply Quote

This is a good simple diagram. There is indeed a 2 phase electrical system. I have heard of it numerous times, first time way back in trade school, it was referred to as a 2 phase 5 wire system. I have never seen one or meet anyone that has but apparently there are still some out there. There was still a reference to them in the NEC a few cycles ago. Just to mix it up some more, there are multiple types of tree phase as well. A WYE system was mentioned and it is very common, there is also a Delta system which is still widely used and many variations of both.

I've been a licensed electrician now for 30 years and I'm still learning things every day!!!!! My trade school instructor always said " your text book says electrical theory! ". It's still fun though even after 30 years!

|

|

old243

Member

|

# Posted: 9 Jan 2017 12:04pm

Reply Quote

I was involved with the electrical utility end of power supply , in my former life. A small municipal utility. With 2400 primary supply. Almost all 3 phase customers were supplied at 240 volt delta. in some cases if 3 primary wires were not available to the service, and 2 phases were. We would supply the service with open delta , using 2 transformers, where the third phase was created from the way it was connected. I think this could be a floating neutral or wye connection that was not grounded. Usually this would be used where the load was smaller. There were also some supplied at 550 delta, as the wire and motor size , were more economical. As the delta motors were not grounded. Any services being upgraded were changed, to a wye connection to give a safer condition as the wye point and the services could be grounded. Also single phase power was then available from the service.

Typical secondary wye voltages supplied were 600 - 347, and 120 -208. Depending on what the customer required. I have been away from the utility , for about 20 years. So likely some policies have changed in the meantime.

As a mater of fact , I was talking to a rep of the local supply authority recently . He tells me that they intend to upgrade the primary supply voltage to 4800 volt from 2400. This will in effect double the system capacity .But at considerable expense.

I realize this is straying a bit from the topic, but thought it might be of interest. My utility experience covered 36 years, so there were many policy changes. Old 243

|

|

DaveBell

Moderator

|

# Posted: 9 Jan 2017 03:56pm

Reply Quote

So many smart folks here. Maybe we should recommend changing the site name to Small Cabin Physics, Dynamics, Engineering, and Astonishing Design?

|

|

TerraLove

Member

|

# Posted: 9 Jan 2017 04:52pm

Reply Quote

Everyone should be on at least 220V.;)

A 220V kettle boils so much faster than 110!

|

|

Cowracer

Member

|

# Posted: 9 Jan 2017 05:35pm - Edited by: Cowracer

Reply Quote

Quoting: old243 I think this could be a floating neutral or wye connection that was not grounded

I've always heard it called a wild-leg 240. Leg-to-leg is always 240V but leg to ground can be funky. I've seen 340 to ground on a 240 system. I cant recall every seeing a it in a Wye. Its always been delta (at least on the 240 side of the xfmrs)

Around my cabin is SWER (single wire earth return). I'm not sure what the primary voltage is, 19kv would be my guess. With a SWER, the xfmr is basically 2 transformers in one can wired in opposing polarities with the center point grounded. That gives you your 240/110 system, but it plays hell with anything with a GFCI on the cord (window A/C, pressure washers, etc). For some reason GFCI breakers and wall outlets seem to do just fine.

SWER is easy to spot, there is literally one wire (and a static line) on the poles. Cheap to install, but you lose some in efficiency.

Tim

|

|

low277

Member

|

# Posted: 9 Jan 2017 08:56pm

Reply Quote

I worked on some open delta 3 phase systems on large farms in the 1980s, They were fairly common in this area back then. I don't know if there are any left around here. I also remember 2400 volt utility primary voltage. I currently work at a manufacturing plant where our utility primary voltage is 14,800 volts with multiple 1500 kva oil filled transformers to reduce the voltage to 277/480 wye system 3 phase which enters the building.  Fun stuff!! It's also good to get away from it all and enjoy the simpler things in life!!!! Fun stuff!! It's also good to get away from it all and enjoy the simpler things in life!!!!

|

|

old243

Member

|

# Posted: 9 Jan 2017 09:58pm

Reply Quote

Cow racer, with the single wire primary and earth return, can you have return flow, problems with drier soil. I have seen problems with an open neutral connections or bad connections, causing tingle voltage . Especially with livestock, waterbowls , metal stabling etc. I would think the grounding would have to be well done. I had heard of this system , but have no experience, with it. Very good discussion.old243

|

|

|