|

| Author |

Message |

offgrididaho

Member

|

# Posted: 17 Oct 2018 01:07pm

Reply

Curious what type of wiring people use for ground/pole mounted solar panels. I am going to have a relatively long run (~100') from panels to controller, so will be using 8 gauge wire.

Seems my choices are to either use duplex marine wire buried in conduit or direct burial Romex.

Concerns with the duplex are I believe I'll have three sets of wires going from three 325w panels, so could require rather large conduit and/or multiple conduit runs.

Concerns with using Romex are pairing stranded wire with solid wire on each end. I'm coming from marine world so haven't used solid wire much, can you use heat shrink ring connectors on it? How about MC4 connectors?

-- Bass

|

|

Nate R

Member

|

# Posted: 17 Oct 2018 01:21pm

Reply

Combiner box with screw terminals would be the ticket here. Will the panels be parallel or series connected?

|

|

redwolfguild

Member

|

# Posted: 17 Oct 2018 02:08pm

Reply

8 AWG at 100' is going to be costly. Hopefully, you are running them in series to increase voltage.

|

|

ICC

Member

|

# Posted: 17 Oct 2018 02:13pm - Edited by: ICC

Reply

Quoting: offgrididaho three sets of wires going from three 325w panels

No. The panels are either connected in parallel or series using the MC4 connectors. Choice of series or parallel is in part, determined by the capabilities of your charge controller. If a parallel configuration is used a combiner box would allow for connecting all three panels into a single set of wires to go the 100 feet. If the panels are in series you would just need a junction box that would allow connecting the panel wires to the transmission wires.

You will get the best advice if you tell us the panel specs as well as the CC specs. Plus what is the coldest temperature the panels will operate in. Another question is whether or not this system will be inspected or has to meet code.

|

|

offgrididaho

Member

|

# Posted: 17 Oct 2018 02:28pm

Reply

Specs are not totally set in stone yet, but here's what I'm leaning towards:

Three 325w 48v panels. Due to distance and voltage drop my plan is (was?) three runs of 8awg wire (one wire pair per panel) and combine them with a bus bar in the shed. So essentially 3 48v panels run in parallel but not parallelled until they get to the shed.

If I paralleled them at the panels themselves, then I'm looking at ~30a at 48v which would require 2awg wire... am I better off using a single run of 2 then three runs of 8 (I mean technically, I know there are cost considerations too but I'm more interested in doing this right than cheap as far as wiring goes).

One challenge if I go bigger (like 2ga) is I don't have the tools to properly attach a ring terminal to that size wire. And the charge controller I was planning on using (Victron 150/35) only accepts 6ga or smaller wire, so I'd have to find a way to go from the 2ga to a bus bar (or something else) then to 6ga or smaller to go to the charge controller.

Coldest temps are probably low 20's MAYBE high teens F.

|

|

ICC

Member

|

# Posted: 17 Oct 2018 02:39pm

Reply

going into what voltage of battery bank... ?

|

|

offgrididaho

Member

|

# Posted: 17 Oct 2018 02:42pm

Reply

Sorry, 12v battery bank, FLA, 6 golf cart batteries (660ah total, 330ah usable).

|

|

ICC

Member

|

# Posted: 17 Oct 2018 03:05pm

Reply

You should rethink this whole thing.

If you do need 3 x 325 watt panels the Victron mentioned cannot handle the total watts with a 12 volt battery. The specs show the following maximum watts at these battery voltages---

12V: 500W / 24V: 1000W / 36V: 1500W / 48V: 2000W

Panels in series would be the way to go for 3 x325 watt and 100 feet distance. But again, that Victron won't do; the series voltage, adjusted for cold temperatures will be higher than what that CC can handle.

A 24 volt battery system would just be okay for 3 x 325 watt worth of panels. Chances are the system will very seldom have such great sun that you get the full rated output, but it does happen.

Victron equipment is good but you may be better off with a CC that can handle 250 or 600 volts incoming from the panels.

Or do 4 panels in a series - parallel configuration?

|

|

|

ICC

Member

|

# Posted: 17 Oct 2018 03:08pm

Reply

I believe Victron has a string sizing tool; either a webpage or maybe a downloadable spread sheet. They are ideal for sizing things and being certain they can work together well. Midnite, Outback and Schneider have such online tools available. Panel data and the series-parallel setup, low temperature, etc are all entred and they indicate best choices for their own brand CC.

|

|

offgrididaho

Member

|

# Posted: 17 Oct 2018 03:44pm

Reply

ICC and others, thanks very much for your replies.

I thought the Victron spec was based on the incoming voltage not the battery bank voltage, so I misread that.

Just ran the voltage drop on 10a @ 144 volts (if I did all three panels in series) that would only require 12awg wire which would be easier to manage and less expensive.

Do people use a combiner box to series their panels or just the MC4 connectors? Presumably if no combiner box with breakers then you need to fuse the wire from panels to controller.

Just need to find a charge controller that is good with that kind of voltage. It looks like the Victron 150/45 would work if I went 24v:

Nominal PV power, 12V 650W

Nominal PV power, 24V 1300W

Maximum PV open circuit voltage, 150V absolute maximum coldest conditions, 145V start up and operating maximum

... open circuit voltage of the panels are 45 volts so 135 total if all three in series.

But that seems to be pushing it, perhaps better to go with their 250 series to have a wider margin on the incoming voltage... the 250/60 specs at:

Nominal PV power, 24V 1720W

Maximum PV open circuit voltage, 250V absolute maximum coldest conditions, 245V start-up and operating maximum

Going to 24v means multiple of 4 on 6v batteries though, so I'd have to decide on 4 or 8 instead of 6... perhaps with a little more PV than I really need I can get by with less battery storage. Or go with 12v batteries in series/parallel to get a 6 battery 24v bank.

This may all be getting a little away from me too as I don't think my energy use is going to be very extreme, I am calculating somewhere between 200 & 300ah per day (depending on time of year) and that's really a very pessimistic estimate, I think we'll use quite a bit less (no 12v fridge, no well or water pump, just lights, radio, TV, computers, tablets, occasional microwave or toaster).

Fortunately my build won't be happening until next spring so I have plenty of time to come up with ill informed ideas and hopefully improve on them!

Thanks again.

-- Bass

|

|

creeky

Member

|

# Posted: 17 Oct 2018 04:01pm

Reply

Three 325s in series are probably around 100v. Idaho isn't that cold. You should be okay.

That would be 100v at 10 amps. Or 1kw of power. Rounding here of course.

A victron 150/35 at 48v battery nominal is 1750 watts.

So that would work well.

At a 100v basic 10g RVPU (solar cable) will have no problems carrying that v/a 100'.

Note: A 12v battery with FLA has 20% dod not 50. Have a good look at the life expectancy chart vs dod that the battery mfctr provides. You basically have <2kw of solar storage there. So your 3 day bad weather loads would be around 700w per day.

Or the same amount of usable power of 1 50ah lithium battery at 48v. Except the lithium battery will recharge with an efficiency of 1. While the lead acid will recharge at peukert of 1.29-1.34. Meaning you have to generate at least 20% more power to charge your batteries.

Also note that a 48v inverter is 94% efficient vs 88% at 12v. Just another way to gain system efficiency and lower cost on BOS (balance of system).

|

|

ICC

Member

|

# Posted: 17 Oct 2018 04:47pm

Reply

Quoting: creeky Three 325s in series are probably around 100v.

Three 325 watt Panasonics like I have seen have a Vmpof almost 60 volts with a Voc around 70 volts. Generalizations are bad, IMO, that's why I asked for specs and by that I did not mean speculation.

|

|

offgrididaho

Member

|

# Posted: 17 Oct 2018 04:50pm

Reply

Actually it is quite cold in Idaho, about 75 miles north of here Stanley, Idaho is often coldest place in the country in the winter, -40 (F or C, take your pick) is not unheard of.

But the cabin is in Washington, near the water, pretty moderate, 15F is about as cold as it gets.

I don't ever like pushing the limits of a particular product, I like a margin of error... for three nominal 48v panels I'll be much more comfortable with a charge controller that can handle 240-250v than one that can handle 145-150v.

-- Bass

|

|

Steve_S

Member

|

# Posted: 17 Oct 2018 05:46pm - Edited by: Steve_S

Reply

Here's a pic (logical) of my setup which may answer some questions. NOT all panels are equal, moreso now than ever before and with bi-facials doing up to 475W everything is changing up fast... keep your eyes peeled for great deals.

I have 8, CSP-260W panels with a 4 & 4 combo that feed into #10 AWG-NMWU (as it is in conduit & underground) that runs 50 feet. I am tittering on the edge there but it's fine, I just won't be able to add more panels to that run and that's OK as I will be installing 4 more in a different spot.

Hope my drawing helps a bit, I do check in here but not regularly at this time... The Real World has me busier than a Long Tailed Cat in a room full of rocking chairs.

REF: Everything else shown in my drawing is easy to find BUT the Combi-Inverter/Charger which I have is not easy to locate info on. There are several off-shore ones that look similar but are NOT, mine is a YiYen (yes Chinese) which I bought from here as it is a "Marine Class" one that has extra goodies built in. here are the specs from the company I bought it from... Check out the $ ! Amazing Deal TOO ! http://www.energie-abordable.com/EN/Inverter-APC-EN.htm

Cabineer 2KW Solar Sys Diagram

|  |  |  |

|

|

creeky

Member

|

# Posted: 18 Oct 2018 10:30am - Edited by: creeky

Reply

Quoting: ICC by that I did not mean speculatio

I didn't see the ogi's post. Wasn't up when I wrote my reply. But anyone who can't use reference points is missing just that. Not sure why I'm getting the attitude?

OGI. I wouldn't run close to 150 (ie. open circuit of 145 as you have stated.) The 250 victron starts at 60a and is fairly pricey. What a lot folks do is run 3 panels in series for the summer/fall/spring and take one panel out for winter.

Most solar controllers handle over amps. Most release magic smoke with over voltage.

I really like the 250v MPPT controllers that are emerging. Makes life easier wiring wize.

Hey Steve. Nice pic!

|

|

offgrididaho

Member

|

# Posted: 19 Oct 2018 08:59am

Reply

Thanks all and thanks for the schematic, reminds me it's time to do version 3 of my planned setup. Drawing it out often helps me find the weak points of a planned build... I will post it here for roasting when it's done.

I agree on the 250v controllers, I didn't really know they existed until y'all pointed it out. Seems like it would make adding additional panels really slick, just add a new panel(s) in series and your voltage drop is actually less at the higher voltage and same amperage.

-- Bass

|

|

Steve_S

Member

|

# Posted: 20 Oct 2018 11:21am

Reply

Hey Creeky… Thanks but BIG SHNOOTZ that's the wrong pic ! (problem with using diff computers that aren't synched) I'll upload the correct one as ref for anyone if they are interested. Such is what it is for being a tad harried & rushed. I'll update this in a few days when I log back in.... busy... busy...

FYI Just had a meeting with some of the solar boyz… seems COTEK changed stuff in production, failure rates are really high and warranty claims have become extremely problematic... Even Rob is dumping Cotek and now considering alternates like AIMS for the lower end stuff.

|

|

Steve_S

Member

|

# Posted: 22 Nov 2018 05:28pm

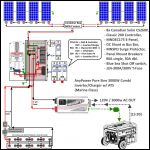

Reply

Back with the Correct & Updated pics from my solar system. Hope it helps anyone who's doing their research.

I included the panel wiring too if curious and an actual photo of the setup, I do have better photo's but it catches the majority, hopefully the web site won't squish it down too much.

Hope it helps, sorry it took so long to update my reply.

Our Solar Diagram

|

Power House Panel - LOGICAL

|

Main Cabin Panel - LOGICAL

|

Solar Room Actual

|

|

|

offgrididaho

Member

|

# Posted: 23 Nov 2018 12:17pm

Reply

Steve_S,

Thanks much for posting your schematic, really helps to see other people's layouts. Have you been happy with the components you chose? Both your charger controller and inverter/charger are less expensive than the Victron items I've been eyeing (I just have a little experience with Victron and like their products), I will have to investigate what you used a bit more.

So it looks to me like you only have a single pos/neg pair running to/from your batteries for both charging and discharging? I was planning on running two pairs as single pair always confuses me with shunt etc., but maybe this is more accurate and efficient way to go?

-- Bass

|

|

offgrididaho

Member

|

# Posted: 23 Nov 2018 12:20pm - Edited by: offgrididaho

Reply

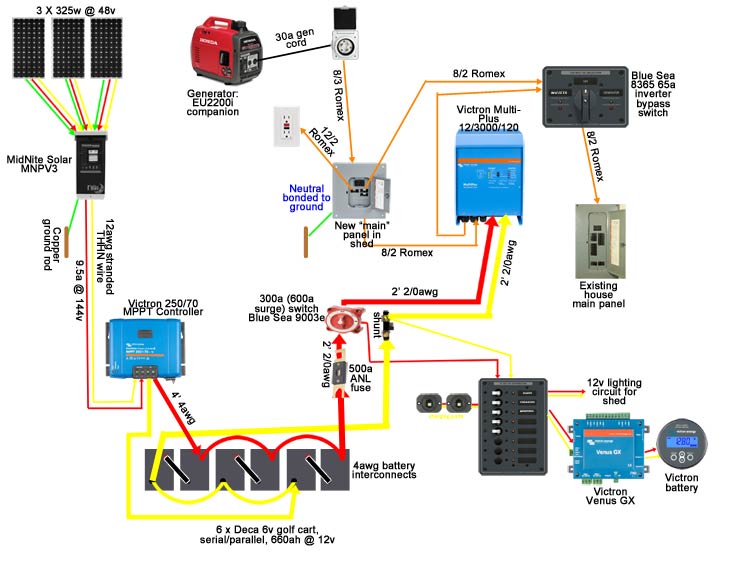

Here is my (current... version 3, really) schematic plan:

If the web view is squashed here's link to full view:

http://www.pictureofnectar.com/outside/All.11-23-18.png

Any comments / input / roasts appreciated.

-- Bass

|

|

Steve_S

Member

|

# Posted: 23 Nov 2018 06:15pm

Reply

Well I used Midnite stuff obviously, so no worries there and I followed their schema as adapted to my particulars. It really came town to simpler, logical and knowing it all works as it should.

I know of Victron as they have been in the electronics industry for quite some time and always had good rep but being on a limited budget I opted for somewhat different routes to get to my destination. Also, I see your running up a 12VDC panel which begs to wonder why if it's just lights ? You could make it entirely independent if you wanted, or as a backup... but really with the new LED lights out today a 4w one is = 40w and if you get the "daylight" type they are quite bright.

As my Inverter is also a full charger (including de-sulphation) it uses the same cabling... on a charge mode it's not much issue BUT if you want to desulphate, then everything else has to be shutoff with the exception of the 175A breaker. As a "Marine" inverter, it is also coated to resist salt air & corrosion (electronics too), not that it matters much in my case but what the heck, couldn't hurt anything eh. One cool bonus is that I can use it either as a UPS "if" I had grid power with Utility Priority mode or as I do now as Battery Priority and only using "utility" (my genny) as backup to charge batts or bypass to cabin.

Here is a link to the company who I got my inverter from. It's in Montreal Canada and French so I used google translate to convert the page link. These are "APC" "AnyPower Combi" and while there are many others that appear same (generic box & design in China) they are not necessarily the same... For Example there are AIMS & Go-Power Inverters that look similar but different specs.

https://translate.google.ca/translate?hl=en&sl=fr&u=http://energie-abordable.com/ondu leurs-APC.htm&prev=search

BTW: I put in a 24vdc to 12vdc converter so I can have full 12 VDC if/when I need or want it as a backup. Haven't needed it but good to have in case. My Power House is also my Pump House with my 40 gal pressure tank, so I heat it to 10C/50F in winter with a small direct vent furnace ripped out of an old RV that uses it's own 12V Battery & Solar Panel. Ironically, the furnace uses a pilot light which I'm not keen about BUT it actually radiates quite a bit of heat in that super insulated 6x14 building (floor is frost protected slab with radiant pex {not in use} & w/ R20 foam around & under it , walls are stuffed with 3.5" XPS with 1" XPS between studs & wall sheathing) and roof is stuffed 4" XPS and all sealed tight like my cabin).

I should note, that while I have several circuits, that is done in a manner which allows for future growth / expansion, even to where I ran both AWG #8/3 NMWU and AWG #6/3 NMWU, while I'm only using the #8 the #6 is coiled for the future... As for load, because I'm a power miser ! (maybe even scrooglely) all lights are LED, everything can be turned off and all low power use stuff... even my computers (except for my 1000w heavy gamer which is rarely used now). The biggest beast I have is my fridge which is a Danby Energy Star 10 cu' apt type unit that uses 267 kwh per year, and I suppose my Well Pump which is a soft start 120V unit 260' deep and 50' from house but I haven't a clue what that pulls.

PS: I'm in North Eastern Ontario Canada so it get's flippin cold out & I "HATE the cold.

Hope it helps, sorry got a wee tad off track but I hope it's helpful too... I do ramble on occasionally trying to be too informative... LMAO... Have a Great One and good luck...

Remember with your Power System... Keep it Simple, Keep it Safe and DC is NOT AC so the rules are different, therefore double, triple & quadruple check it all. Hint, even the floor in my powerhouse is 1" thick rubber horse mat, 1st rule of crisis management is PREVENTION ! hehehe just in case.

|

|

offgrididaho

Member

|

# Posted: 24 Nov 2018 08:48am

Reply

Quoting: Steve_S Also, I see your running up a 12VDC panel which begs to wonder why if it's just lights ? You could make it entirely independent if you wanted, or as a backup... but really with the new LED lights out today a 4w one is = 40w and if you get the "daylight" type they are quite bright.

Thanks for your detailed reply Steve_S! I don't have much input on any of this stuff around where I live (strangely) so it's always awesome to hear and see details of how people built their systems.

As far as the 12v panel, if there's an easier / cheaper way to do 12v in the shed I'm game. I eventually want light in the shed (there is none now, I don't want to split the output from the inverter, don't want to have to run the generator any time I want light in the shed) and I'd also like it as a backup spot to charge phones / tablets / lanterns if everything else goes sideways (figure if the batts are good, the cables are good, you can see everything in front of you, you can probably at least get solid 12v in the shed).

-- Bass

|

|

creeky

Member

|

# Posted: 24 Nov 2018 11:17am

Reply

OGI I have a few thoughts. ;)

One. You don't have a disconnect solar controller to battery. You need one.

Two. Your ANL fuse is the wrong type. You need a slow burn Class T at that size.

Three. Why 12v? Can't you buy 8 batteries (or better yet move to lithium) and go 24v or 48.

Four. Your batteries should be wired to a bus bar. Wiring your batteries in the way you have them puts the drain on the end module. The input on the first module. And the middle will never see the same work load. Particularly with lead.

I wire all my battery modules to a bus bar. Put the output fuse on the bus bar (to the inverter). A switch between the solar controller and the bus bar. This is easier to work with. Lets the batteries work more easily.

Five. There are lots of 24v lights. 24v would save you a lot of wiring costs as you cut your amps by 1/2. Lose all that 2/0

Six. I gotta stop. But your stranded from the combiner to the Victron solar controller MUST be high stranded (as per the installation requirements from Victron). You should use at least 60 strand. I use the super fine from Bntech online from that web retailer.

Seven. You've got your panels sending 6 lines to the combiner. You will only send 2. You've described the panels as being in series. So you will plug pos from panel 1 into neg from panel 2; pos from panel 2 into neg of panel 3; neg from panel 1 and pos from panel 3 will run to the combiner.

Your equipment choices are excellent. I love Victron. But I would rethink the voltage to take advantage of the increased efficiency. And make a few tweaks to the BOS.

For those building similar I have a "simplified solar schematic" available that should help.

|

|

offgrididaho

Member

|

# Posted: 24 Nov 2018 08:53pm

Reply

Quoting: creeky OGI I have a few thoughts. ;)

Ha ha, awesome!! Seriously, I appreciate all the input. I don't have much experience with solar on this scale (have done a few smaller systems on boats and vans but nothing). And I'm here to learn, so don't hold back

Quoting: creeky One. You don't have a disconnect solar controller to battery. You need one. Two. Your ANL fuse is the wrong type. You need a slow burn Class T at that size.

Got it. I have now looked at the simplified solar schematic linked below and see that I missed the disconnect. And I threw the ANL fuse in there for reminder to myself knowing I should investigate more, I've used Blue Sea's (assuming they recover from their fire!) MRBF holders on the batteries in the past but they're not high enough amperage anyway.

Quoting: creeky Three. Why 12v? Can't you buy 8 batteries (or better yet move to lithium) and go 24v or 48.

I'm not quite ready to pull the trigger on lithium, both from expense and I'm not a great early adopter, so at this point sticking with the lead (I know, I know).

As for the first question, "why 12v?" I was all set to give my answer and I just don't have one... vague thoughts about the DC panel in the shed being able to charge things blah blah, none of it makes sense. Easy to do low amperage converter down to 12v for the very few things that would only charge on 12, as you mention lights at 24v (or even 48v) aren't hard to find. So I will plan to go up in voltage.

At 24v or 48v I could downsize to the 250/60 MPPT controller and save $100 right there.

The MultiPlus Inverter/Charger 12/3000/120 (24/3000/70) I was looking at will only do 12v or 24v, I could go 48v with the Quatro 48/3000/35 (very similar specs) but that adds ~$300. Choices choices.

Quoting: creeky Four. Your batteries should be wired to a bus bar. Wiring your batteries in the way you have them puts the drain on the end module. The input on the first module. And the middle will never see the same work load. Particularly with lead. I wire all my battery modules to a bus bar. Put the output fuse on the bus bar (to the inverter). A switch between the solar controller and the bus bar. This is easier to work with. Lets the batteries work more easily.

OK, based on the above I did some more reading and see what you're saying about the bus bar, thanks. Only question I would have is is it "best practice" to use a bus bar even if I did 8x6v batteries in series to 48v (so it's basically 1 battery)?

And this decreases amount of the (not 2/0 if I go up in voltage, but still large) wire I would need to use too

Quoting: creeky Six. I gotta stop. But your stranded from the combiner to the Victron solar controller MUST be high stranded (as per the installation requirements from Victron). You should use at least 60 strand. I use the super fine from Bntech online from that web retailer.

Only issue I have with the Bntech is I'm looking at a 100' run, can only find their cable in 50 spools, don't want to have a crimp (even the best I can do with my average skills and OK tools) in the middle of my buried conduit if I can help it. But I imagine I can find other wire that fits Victron's specs.

Quoting: creeky Seven. You've got your panels sending 6 lines to the combiner. You will only send 2. You've described the panels as being in series. So you will plug pos from panel 1 into neg from panel 2; pos from panel 2 into neg of panel 3; neg from panel 1 and pos from panel 3 will run to the combiner.

The way you're describing wiring panels in series is how I've done it before. I misread the MNPV3 specs and thought it was combining the panels in series, rereading I realize it parallels them, so it would only get one positive and one negative lead into it.

Quoting: creeky For those building similar I have a "simplified solar schematic" available that should help.

So not knowing your background (other than a bunch of replies you've already generously shared on threads I've started), is bobolinksolar.com your gig?

Thanks again for your feedback.

-- Bass

|

|

creeky

Member

|

# Posted: 24 Nov 2018 10:45pm

Reply

You can run basic RVPU solar cable to a power terminal then run a whip (short extension cable) to the solar controller.

Just remember. Lithium makes your whole system 20% bigger for free. Then take the lower cycle cost.

Ya bobolink is my biz. Having loads of fun. Built somw great stuff this year. Doing some cool stuff for next season.

|

|

offgrididaho

Member

|

# Posted: 1 Jan 2019 05:57pm

Reply

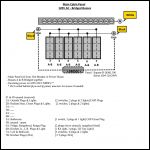

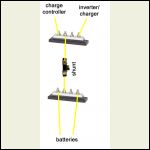

Quoting: creeky Four. Your batteries should be wired to a bus bar. Wiring your batteries in the way you have them puts the drain on the end module. The input on the first module. And the middle will never see the same work load. Particularly with lead. I wire all my battery modules to a bus bar. Put the output fuse on the bus bar (to the inverter). A switch between the solar controller and the bus bar. This is easier to work with. Lets the batteries work more easily.

Creeky,

if I go with a bus bar (which I will because what you noted above makes perfect sense), I would have a total of four positive wires to a positive bus bar (charge controller, battery, battery, inverter/charger). Makes sense to me. Same total of four wires to a negative bus bar (charge controller, battery, battery, inverter/charger).

Question on the negative bus bar is how can one wire a shunt in there correctly to read amps in and out? Do you have to do two bus bars (one bus bar would have two wires from batteries to the bar, second bus bar would have wires from charger controller to bar and inverter/charger to bar) and then run a jumper wire between those two bus bars with the shunt in between?

Attaching detail of current schematic where batteries are concerned, and possible way to do this that I described above, but would like to hear better ideas.

Thanks in advance!

-- Bass

Details of schematic around bus bars

|

Possible way to wire shunt?

|  |  |

|

|

scott100

Member

|

# Posted: 5 Feb 2021 11:47pm - Edited by: scott100

Reply

Just a thought. Is there a way to put your inverter close to the panels and then run 120 v ac from there? It would make wiring to the cabin a whole lot cheaper and easier.

In our case, I have a shed in out in the field. 6 x 160 watt 12v panels on the shed roof. They are wired series parallel for a 24v system. The vicron 150 35 controller is in the shed along with the 8 x GC2 6v golf cart batteries and the 300 watt Aims inverter. 120 v ac is run the distance to the cabin with aluminum direct burial wire in conduit.

Concerning fusing at the batteries, being a boat guy myself I use Blue Sea MRBF fuses at the battery terminal.

|

|

scott100

Member

|

# Posted: 5 Feb 2021 11:54pm

Reply

Just noticed that this thread was dragged up from a couple of years ago...shoulda noticed the dates on the posts more than just the one before mine. The OP's probably had his solar in for the last 2 years.

|

|

|