|

| Author |

Message |

brentron

Member

|

# Posted: 25 Apr 2020 05:33pm - Edited by: brentron

Reply

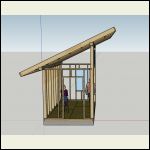

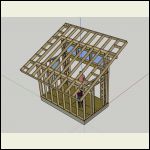

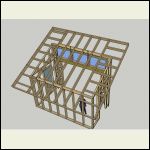

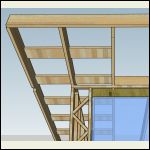

Here's my plan for a small cabin. I'm putting a big opening (about 10') to make it feel bigger and a big front overhang so I can keep the door open in all but the largest storms.

The oversized overhang (almost 4') is held up by cantilevering the rafters! The side overhangs are also extra long at 2', and are held up by a 6x6 purlin sitting on top of the top plate. Some very non-standard things to this design for sure! For example: the rafter birdsmouth is cut as if it's sitting on a standard 4" top plate, rather than going all the way over the 6x6. This is to keep strength in the rafter so the cantilever is still strong.

Here's a link to the Sketchup design. You can click on it and zoom in and look around in 3D to see the details: https://3dwarehouse.sketchup.com/model/d16fdffa-3131-4866-b1dd-bb8cf8cba84c/8x14-Shed -Workshop

Screen_Shot_202004.png

|

Screen_Shot_202004.png

|

Screen_Shot_202004.png

|

Screen_Shot_202004.png

|

|

|

ICC

Member

|

# Posted: 25 Apr 2020 05:39pm

Reply

Got a drawing? That helps some of us, like me, know exactly what you are talking about. Dimensions too; width of cabin, etc.

|

|

brentron

Member

|

# Posted: 25 Apr 2020 05:52pm - Edited by: brentron

Reply

Quoting: ICC Got a drawing? That helps some of us, like me, know exactly what you are talking about. Dimensions too; width of cabin, etc.

I just edited to post screenshots of the sketchup as well as a link to the Sketchup itself. You can go to the link and pan and zoom in on the design.

Dimensions are 8.5' x 14'. Portal opening is 9'10.5". Roof is 18' x 16'.

|

|

Brettny

Member

|

# Posted: 26 Apr 2020 08:22am

Reply

A 6x6 is not that strong or needed in the horizontal position. Double up the 2x facial material, run the wall top plate long and use the blocking correctly on the over hang. 2' should not be a problem. No 6x6 needed.

If you feel the need use angle braces to the wall or if your rafters are 2x6 use 2x8 for the overhang facia/last rafter.

|

|

brentron

Member

|

# Posted: 26 Apr 2020 09:57am

Reply

Quoting: Brettny Double up the 2x facial material, run the wall top plate long and use the blocking correctly on the over hang. 2' should not be a problem. No 6x6 needed.

I'm having trouble following this. Does doubling the 2x facial material mean the using twice the studs in the side walls? And what does running the wall top plate long mean? And what is meant by using blocking correctly on the overhang, I thought it already was correct blocking?

|

|

brentron

Member

|

# Posted: 26 Apr 2020 10:23am

Reply

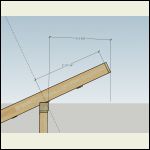

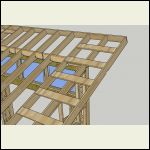

@brettny, is this more along the lines of what you're suggesting?

I had considered something like this but I'm worried it doesn't provide enough strength for the long overhand on the high side (what I'm calling the front).

Screen_Shot_202004.png

|

Screen_Shot_202004.png

|  |  |

|

|

ICC

Member

|

# Posted: 26 Apr 2020 11:14am

Reply

Do a search for fly rafter and ladder rafter

|

|

ICC

Member

|

# Posted: 26 Apr 2020 11:34am

Reply

I see your intent with the 6x6. You intend them to carry the load on that outrigger rafter. The conventional method of fly or ladder rafter framing is superior. Don't try to reinvent the roof.

I also wonder how much good that front overhang is going to do? It is very high above ground, tilted upwards.

The entire overhang amount seems too large for a small building. Just doesn't look right to me. It also raises the question of how well is the roof going to be anchored to the walls as well as how well will the structure be connected to the ground. It looks like a sail and in a big wind that could be a problem.

|

|

|

ICC

Member

|

# Posted: 26 Apr 2020 11:43am

Reply

To me, the zig-zag blocking on the front wall corners is a waste of effort. It will also make spray foam the only practical type of insulation that will be effective, IMO. If the intent is to brace the wall corners, that is what the exterior osb, plywood, or other panels are going to provide. Wall bracing panels should be a full 4 feet wide by the height; that is the simplest way to meet strength and anti-racking requirements. Simpson does make special narrow bracing units. Google portal wall or portal frame. This is how garage door openings are framed--- that front wall is much like a gargage door wall.

three links 1 2

3

|

|

Nobadays

Member

|

# Posted: 26 Apr 2020 11:54am

Reply

Quoting: ICC I also wonder how much good that front overhang is going to do? It is very high above ground, tilted upwards.

A porch roof over this outside area would be much more effective at keethis space dry. IMO it would also balance out the building astheticly.

I'm a bit skeptical of a space that is only 8' x 14' with this large opening. As a Tiny house this drastically limits the usable space within the structure. But it is your place... maybe try doing your interior layout to see how you can utilize the space. Just food for thought.

|

|

brentron

Member

|

# Posted: 26 Apr 2020 01:18pm

Reply

Quoting: ICC Do a search for fly rafter and ladder rafter

I actually have been looking in to that, and you can see the attachments how I even put together a model doing that. However, I haven't found any ladder rafter info that is for a shed roof, and especially a shed roof with a long cantilever.

The main thing I'm concerned about is that going with the ladder like that I lose a rafer or I have to put notches into a rafter, which reduces the strength of the cantilevered overhang on the front (the high end).

Definitely understand the concern that others have about the long high overhang on the front. That's really my main concern structurally as well. I really like the design, I think it makes the tiny structure look much bigger than it is. I want to try to find a way to keep it if possible. Of course if I need to for the sake of structural integrity, I can shorten it or lower the pitch of the roof a little. I think I'm pretty close to finding something that works though! It's just tricky balancing the big high overhang with the side overhangs!

Screen_Shot_202004.png

|

Screen_Shot_202004.png

|

Screen_Shot_202004.png

|

Screen_Shot_202004.png

|

|

|

Brettny

Member

|

# Posted: 26 Apr 2020 02:12pm

Reply

Look up what a wall top plate is. It's easy to run long. Useing double 2x6 or 2x8 for the top and bottom facia will add alot of strength with out having to notch anything.

Il take a picture of my garage that I recently added a 12in overhang where it had non prior. The point is to not rely on nails or screws in the end grain of the wood to hold the blocking on. Your original design relays on end grain nailing.

|

|

ICC

Member

|

# Posted: 26 Apr 2020 04:49pm

Reply

Re nails in end grain. It is impossible to not use nails into end grain in some types of construction. The sub-fascia 2x4 or 2x6 are always nailed to the rfater tails or the outboard ends of a truss. Similarly when doing floor framing the rim joists are always nailed to the ends of the 2x floor joists. What saves the day id the sheet (osb, plywood) sheathing that is nailed to the rafters and sub-fascia or to the floor joists and the rim joists. The sheathing ties it all together.

A gable end built with fly rafters or sometimes called outriggers; a ladder rafter system will always have some members nailed to end grain. The sheathing is a needed part that helps maintain the structure.

|

|

ICC

Member

|

# Posted: 26 Apr 2020 04:57pm

Reply

Quoting: Brettny It's easy to run long. Useing double 2x6 or 2x8 for the top and bottom facia will add alot of strength with out having to notch anything.

That confuses me. Maybe I am misinterpreting or maybe the fascia term is actually being used incorrectly. Maye it is just me, but correct names are inportant to me.

A fascia board is trim, often thin and has no structural value. The sub-fascia is usually a 2x4 or a 2x6 and is nailed to the rafter tails or the ends of the trusses. The sub-fascia are single layer and hold the tails in place as well as providing the nailer for the roof sheathing to be attached to. The fascia is just a trim piece that goes over the sub-fascia; could be a 1x, hardboard, cement board, vinyl, whatever looks pretty.

|

|

Brettny

Member

|

# Posted: 26 Apr 2020 05:03pm

Reply

In that pic I'm talking about the sub facia.

|

|

Brettny

Member

|

# Posted: 26 Apr 2020 05:07pm

Reply

Blocking not end grain nailed/screwed. This is my car port bu the same theory can apply.

|

|

ICC

Member

|

# Posted: 26 Apr 2020 05:10pm

Reply

Quoting: Brettny In that pic I'm talking about the sub facia

Thank you. It helps when we all use the same industry-recognized names for components.

|

|

Brettny

Member

|

# Posted: 27 Apr 2020 07:16am

Reply

On my house we used coil stock as what the facia is showing in that pic. So I guess facia could be anything.

|

|

brentron

Member

|

# Posted: 27 Apr 2020 03:24pm - Edited by: brentron

Reply

Quoting: Brettny Look up what a wall top plate is. It's easy to run long. Useing double 2x6 or 2x8 for the top and bottom facia will add alot of strength with out having to notch anything.

If I'm understanding you right, you're talking about having a top plate extend past the wall. I was trying to do that in my initial design--what would you change about it?

Screen_Shot_202004.png

|

Screen_Shot_202004.png

|

Screen_Shot_202004.png

|  |

|

|

|