|

| Author |

Message |

Rickkrus

Member

|

# Posted: 28 Jan 2018 12:49am - Edited by: Rickkrus

Reply

Can anybody give me an idea of the cost of a metal roof installation? I'm debating doing it myself but the idea of a crew coming in and doing it in a day is tempting. I've got around 600 sq ft. I did all the sheathing myself so just underpayment and metal panels.

|

|

toyota_mdt_tech

Member

|

# Posted: 28 Jan 2018 10:55am - Edited by: toyota_mdt_tech

Reply

I just did a metal roof for a 20 foot container, I have 6 feet overhand on door end and the materials alone cost me about $1200

My roof was fully sheeted with 1/2" plywood with 30# felt underlayment.

The panels can be ordered to your length, so it goes pretty quick.

Plan on plenty of fasteners, (double them, they are color matched) do loads of research and follow the mfg rec to a "T". But keep in mind, a simple 5/12 pitch with composition is easy, but with metal, it is treacherous to walk on. Get a harness and tie yourself off.

You want to figure out your profiles, facia cover goes down first, sheeting, gable end, then peak. Peak or cap screws to ridges on panels, not into the roof substrate, metal expands in heat, and the ridges are there to allow expansion. But some tin snips, left and right handed, straights, a brake, and electric shears made it nice if you have to rip a panel long ways. Get the foam blocking that sticks on too, one will go at the bottom of the panels to breath and keep bugs out, other goes on top of panels under the ridge cap to do the same. Good luck, my container my first ever metal roofing job, I sub'd out the cabin, but searched high and low to find the same mfg to match cabin profile and color.

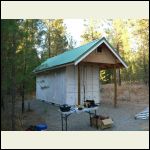

The picture taken of the cabin, I am standing where the container now resides.

P1030004.JPG

|

P1030003.JPG

|

Cabin profile

|  |

|

|

rockies

Member

|

# Posted: 28 Jan 2018 07:05pm

Reply

One thing I would consider using instead of felt underlayment is a product called Versahield Fire Deck membrane.

http://www.gaf.ca/Roofing/Residential/Products/Roof_Deck_Protection/VersaShield_UL_Fi re_Barrier

Despite being metal, a wildfire will transmit so much heat through the metal sheets that it will set the plywood sheathing on fire. This will help prevent that.

|

|

toyota_mdt_tech

Member

|

# Posted: 28 Jan 2018 10:56pm

Reply

Good point rockies. I am headed up in April well ahead of fires season to do major clearing, I will leave a large fire break from the container. Buying a new DSR chipper and extended chute and going to grind up loads of trees around container.

|

|

benny8

Member

|

# Posted: 13 Feb 2018 03:49am

Reply

My cabin is 16'x28' with a 5/12 pitch. The metal was 10' long x36" wide. 10 sheets per side. My cost for the metal, screws and ridge pcs under $500. My father got on the roof and I worked the eaves. Installed and capped in 2 hrs. The last half hour was pouring rain. I'm not sure what kind of shoes my father had on, but he could walk on the metal in the rain with no slippage. It helps that we have done a few metal roofs together. I will say that if you are installing metal over plywood, be sure to set the clutch on your driver as to not over tighten the screws( read as stripping so the screw just keeps turning). My cabin sub roof was shiplap pine with the synthetic roofing underlayment. The synthetic underlayment is leaps and bounds better than black paper. Best of luck.

|

|

KinAlberta

Member

|

# Posted: 13 Feb 2018 11:55am - Edited by: KinAlberta

Reply

A couple tips I’ve heard - but subject to check with an expert:

Pre-drill all the holes through batches of sheets.

Reverse the blade on a circular saw to cut panels.

Good seals around chimneys etc - I don’t know. I’m not overly impressed with the mastic method used on ours, so I want to put shrouds or flanges over them as extra water shedding protection.

Plus our one day job of two buildings was done quick by a couple friends so they wouldn’t have to come back the next day. As a result one small chimney pipe is now angled due to a very small mis-measurement for centering the pipe - so it got pushed a bit to one side. (I wasn’t there when they did the roofs and was just happy that I didn’t have to hire some expensive roofing company. However someone on the ground watching for little things like squaring and alignment might help.)

Also, make sure your roof is straight beforehand. Ours has a bit of a dip that I want to take out (not sure why yet but expect I just need to sister in a couple straight boards beside weak or cracked rafters) but now have to worry about stretching any screw holes.

|

|

benny8

Member

|

# Posted: 13 Feb 2018 12:01pm

Reply

Quoting: KinAlberta # Posted: 13 Feb 2018 11:55 - Edited by: KinAlberta Reply Quote A couple tips I’ve heard - but subject to check with an expert: Pre-drill all the holes through batches of sheets.

That is very good information. We pre-drilled all our holes first.

|

|

KinAlberta

Member

|

# Posted: 13 Feb 2018 12:22pm - Edited by: KinAlberta

Reply

One point worthy of a separate stand alone post:

Years ago on my father’s 80th birthday my father had a trip off a concrete step. Before that he’d never spent a night in a hospital - wasn’t even born in a hospital. Anyway that fall put him in an electric wheelchair as a semi-paraplegic, with some ability to do things with his hands. That’s life changing in many, many ways plus requires 24-hour nursing care. It’s also very possibly life shortening.

However, in relation to this thread, in the hospital the guy in the bed next to my father had just retired a few weeks before. Apparently he’d gone up on his roof to clean out his eavestroughs and fallen off the roof, breaking his neck and turning himself into a full paraplegic.

So think about that. Work all your life waiting to retire and then spend your remaining years in a bed or wheelchair because you made a little mistake with huge consequences. My guess was that he was trying to save $50 bucks by not hiring someone experienced to do it.

Please re-read the harness point made in a post above.

|

|

|

KinAlberta

Member

|

# Posted: 13 Feb 2018 12:40pm - Edited by: KinAlberta

Reply

Interesting.

A couple thoughts:

I’ve heard that a lot of fires cause embers to get sucked into the roof where they somehow cause the house to catch fire. I guess soffit design and materials matter. I could sure see how hot embers could get dawn up under metal roofing as the heat creates a strong upward draft. This could draw up embers right into the gap between the metal roofing and the underlying plywood sheathing. So some fire protection could make a huge difference.

Also, a lot of metal roofing is just put over the old asphalt shingles. I just couldn’t believe that was a good practice but I read hundreds of posts on roofing and a lot of roofers (significant numbers) have done that for decades without issues.

Soooo... I thought about it and figured that leaving the old shingles in place couldn’t be that bad - and in fact might be good - for a number of reasons:

- leaving shingles provides a rough/gritty and lapped underlay, so they should help provide air circulation,

- leaving old shingles provides a better more closely supported foundation for the metal which should be better for walking around on and maybe making the metal less subject to hail and falling branch damage

- leaving old shingles would allow any water seepage to drain or evaporate

- leaving old shingles would provide a tar seal for all the screws

And now I think I can add

- old shingles still have some fire rating value - so they might do exactly what this membrane material offers to do.

|

|

KinAlberta

Member

|

# Posted: 13 Feb 2018 12:50pm

Reply

Any experience with the different types of snow gadgets? What are they called? breaks?

|

|

Malamute

Member

|

# Posted: 15 Feb 2018 04:27pm - Edited by: Malamute

Reply

Backwards saw blade. I class this with urban legends. Yes, it works, but its hideously loud, makes sparks, and shoots metal particles everywhere. its an extremely annoying practice. Once I saw a GOOD set of metal hand shears in use I never touched a saw again, what a miserable experience.

Like this https://www.grainger.com/product/6MJH2?cm_mmc=PPC:+Google+PLA&s_kwcid=AL!2966!3!16658 9221840!!!g!87507853797!&ef_id=WoX2tAAABG1l940K:20180215211213:s&kwid=productads-adid ^166589221840-device^c-plaid^87507853797-sku^6MJH2-adType^PLA

READ the info that comes with the metal before doing anything, or get a set of instructions befere getting the metal.

Use the correct screws for the sheathing material, ones spec-ed for wood or plywood arent good for use in OSB, the ones for OSB (forget the type name) are larger diameter to hold better. Some people that sell roof metal DONT KNOW theres different type screws spec'ed for different materials. Because some uninformed person told you something at the hardware or lumberyard, and you used the wrong supplies, you may not have a warranty.

Yes, pre-drill the holes. Separate the stack for each side for the desired direction of laps for wind resistance. Use a block underneath the stack, and use a block on top and put a foot or knee on it when drilling, otherwise the sheets will ride up the drill bit, the tip will walk on the next sheet and end up breaking the bit. Bit breakage came to a screeching halt when the blocks were used top and bottom. Learn which way the edges go, the little "foot" is the lower side of the lap, it gives support for the lap edge, the short side is the top of the lap.

The titanium underlayment is pretty good, better than the 30 lb felt if its not going to be covered right away. The wind can ruin felt quickly.

if going over existing shingles, the manufacturers of metal roofing Ive used used to recommend using 1x or 2x nailers/backers over the shingles. They are put on on your screw layout, and screwed down with 3" screws (or whatever they need) to the underlying sheathing. The warranty would be void if you didnt. I used 1x4s for most, with a 1x6 on edges where you may need some wider backing for the screws on extended gable end flashing. Use the wider material on the end edge, not the starting edge. Its hard to get consistent screw washer tension to seal the screw heads with shingles underneath. I never had much luck with drill torque settings, even with solid backing under the metal, I do it by eye on the washer shape. They are supposed to get a certain amount of compression to seal the rubber washer under the cupped metal washer.

Learn how to square up off the length of the building so the sheets dont end up with sawtoothed edges from trying to get them square with an out of square end. Your eave edges will look better and youll be happier in the end. I snap chalk lines to work the squaring off of, then snap check lines every couple sheets worth of run to keep it straight and square. To square it, use the basic 3-4-5 ratio working off a line snapped along the length of the ridge to get the end started and stay straight as you go.

4-12 is pretty easy to walk on, 5-12 isnt bad, 6-12 is doable, but its starting to get interesting, especially if it gets dusty before youre done. ive never tied off an a roof, but am very careful when working on them. I have made ladder shelves on steeper roofs so i could stand on my ladd4r laid on the roof. Working new meta, you dont have to walk on the metal as much when laying it, you are standing on the underlayment, and can step one foot on the metal to run screws, The screws give some purchase to your feet is need be. Shoot the screws along the lap first, standing on it if possible to keep it flat.

Plan your metal length well, you own it after its ordered. be sure to figure how luch hangover you want at the bottom, and if using a vented ridge, what the actual run length will be. I prefer to order metal after the sheathing is on, so unforeseen things dont mess up your plan.

Be sure when laying out the drill marks to get the lines where you want WITH the hangover you desire. In other words, figure the hangover, then how far into the sheathing to screw it, figure that as the first drill row, then usually go 24" steps up from there, and you should miss the plywood joints. Plan it, remeasure, check it again, ask somebody else, then drill. I worked on one that somebody managed to hit ALL the horizontal sheathing joints from lack of planning, so half the rows of screws kept backing out over time from not being torqued correctly. I'm in a crazy windy area, so screw lines every 24" up the run plus the top and bottom ends. Screws on both side of the valley flats on the ends is best, one in each valley flat for the run is enough for our 130 mph winds. Start the layout on the overlapping side to hold it down, and use stitch screws on the rib of the overlap. Dont drill the start side of the first sheet, the edge trim will handle that and you wont have to try to hit the holes.

A black sharpie makes good drill marks and cut lines, chalk lines are also OK for cut lines for valleys and such, or to cut the length of a sheet for the last course.

Wear gloves handling metal. I like deerskin for the grip and feel. When pulling up individual sheets off the stack, keep a razor kniofe handy to get the sheets picked apart hen wearing gloves. DONT drag the sheets across each other, it scratches the paint. Pick it completely up in place.

The ground guy, DO NOT slide a sheet up and stand there looking at it!!!! get the frog OUT OF THE WAY!! If somebody above let it slip out of their hands, you DO NOT want to be IN THE WAY. It could conceivably decapitate you. If the breeze comes up, STOP working, handling metal in breeze is extremely dangerous. I have plenty of stitches to prove it. Also, if the breeze catches a sheet, LET IT GO!! Do NOT try to stop it. Nothing it could do is with getting cut badly or killed over. Make the work area safe for others in case of problems, no pets or kids running around loose or spectators watching close by. Think about this before starting, dont try to play catch up after getting started.

Pay attention to where you are, backing up off the the isnt unheard of. Distractions, like music in your ears and other such nonsense has no place when working metal.

This turned into a book, sorry.

it sounds harder than it is. I enjoy it for the most part, but its serious business, treat it as such, and you should be fine.

|

|

toyota_mdt_tech

Member

|

# Posted: 17 Feb 2018 03:39pm

Reply

Malamute, sounds like you have done a few of these. All great info, I read it all.

|

|

Malamute

Member

|

# Posted: 17 Feb 2018 09:57pm - Edited by: Malamute

Reply

Ive done a few, but by no means am very knowledgeable compared to many. I have seen some pretty poor installations, some by people charging for their time and "experience", so thought Id throw a bit out to hopefully help someone, and encourage them to study up on the matter before jumping in. Its not rocket surgery, but knowing a bit makes it easier, safer, and go faster.

I did a couple projects with a guy that has done a fair bit of metal work, learned some neat tricks for doing certain things.

For neat ends on ridges or gable trims, leaving enough extra to clip them to fold over and cover the open ends makes a neat job. One can also fit pieces in the openings and pop rivet them in place. You can get pop rivets in the same color as your roof metal. Pop riveting the laps on ridges also helps keep them tight and flat.

|

|

KinAlberta

Member

|

# Posted: 18 Feb 2018 07:53am

Reply

Yes, excellent information. Thanks for taking the time to post it.

|

|

Steve_S

Member

|

# Posted: 18 Feb 2018 09:43am

Reply

Well written Malamute ! That should be a Stickied Article on here IMO.

|

|

ILFE

Member

|

# Posted: 18 Feb 2018 10:36am - Edited by: ILFE

Reply

Quoting: Rickkrus Can anybody give me an idea of the cost of a metal roof installation?

Yep. See below.

Quoting: toyota_mdt_tech I just did a metal roof for a 20 foot container, I have 6 feet overhand on door end and the materials alone cost me about $1200

Here is what it cost us, May, 2017, in Cambodia.

7 each - sheets roofing steel (corrugated), snow white color. 3.5 meters long x 1.10 meters wide. $12.95 each, $90.65 total

6 each - 40 x 40 x 1.50 x 6 m long, $7.695 each, $46.17 total

5 each - 40 x 80 x 1.50 x 6 m long, $12.433 each, $62.17 total

1 bag - mounting screws with rubber washers, $3.50 total

Transportation to the farm was $15.00.

Sub-Total: $217.49

Welding cost an additional $70.00 USD, for the trusses, purlins, and to mount them to the container.

Grand Total: $287.49

We've since added a gutter, PVC downspout, and a 1000 Liters IBC tote, for rainwater harvesting.

|

|

Malamute

Member

|

# Posted: 18 Feb 2018 11:36am - Edited by: Malamute

Reply

One can make up a materials list from their roof size, such as the length of metal for the runs on each side, figure the ridge, gable and eave trims, upper and lower closures and/or ridge vent material, ask how many screws for the sq footage or look it up on line, (I always add some, Id rather have 10% extra than 2% under), and figure any required wood screw backers if going over old shingles and such. My local small lumber yard would add up the basics for you if you told them what your sq footage was. Its not that complicated once you get the basic idea of whats needed. Figure flashings for roof vents and such also, they may come from the local hardware or lumber yard. I tended to ask what people were using, sometimes I didnt know, sometimes they had better ideas than me.

I tend to use the mini gable and matching size eave trims, I like the wood showing more than try to wrap everything in metal as seems to be the habit with some.

If going through something like a cedar rough out fascia board, I got long enough screws to make it into the solid sub-fascia. i also did a stepped fascia for the nice look, so the screws on the face of the gable trims needed to be long enough to get through all that into the 2x sub-fascia.

Speaking of stepped fascia, I used a 2x for the upper half of the sub-fascia on the rafter tails, and a 1x for the bottom, with a 3/4" gap between. I cut strips of screen material and stapled across the gap, then bevel cut the edges of the finish rough-out facia so the overlap wasnt noticeable. It made a very clean soffit or eave vent for the roof, along with a vented ride with the metal ridge and versa-vent type closure for the ridge metal. No obvious roof vents for a raftered roof that was open (and finished) underneath in a cabin made it nice visually and was practical.

|

|

lanecabral

Member

|

# Posted: 10 Apr 2023 09:14am

Reply

I stumbled upon this post and thought I'd chime in. From my experience, it's always best to hire an experienced contractor when it comes to metal roof installation, especially if you're not familiar with the process. It may cost you more upfront, but it'll save you headaches and potentially costly mistakes down the road. That being said, if you're confident in your abilities and have done your research, go for it!

By the way, I recently discovered an

that specializes in metal roofing. They might be able to provide you with a more accurate estimate and even handle the installation for you. Just thought I'd share that in case it's helpful.

|

|

rpe

Member

|

# Posted: 10 Apr 2023 11:32am

Reply

I've done a few steel roofs, and there's lots of good info above. One tool I never go without is the powered snips. I've recently been using a set that adapts to your cordless impact driver. I can cut a sheet lengthwise at walking pace. Cutting across the ribs is a bit slower, but not bad. It does take a bit of practice to get the technique down, but is a huge time-saver. It's also quiet, and doesn't leave metal shards lying about.

https://www.amazon.ca/DEWALT-DWASHRIR-Impact-Shears-Attachment/dp/B01BSAWORC

|

|

gcrank1

Member

|

# Posted: 10 Apr 2023 07:40pm

Reply

I Sooo Hate the flying metal chips power sawing

|

|

Tim_Ohio

Member

|

# Posted: 11 Apr 2023 11:03am

Reply

I did my 12 x 24 with metal. I love the stuff. A good metal roofing supply will aid you in getting all of the

parts and pieces. I like the peace and quiet of scoring it and breaking it along the lengths. I used straight cutting tin snips across the ribs. I also bent flaps over what some installers would have left open, such as the ends of the ridge cap, ends of gable runs (where it stops at the bottom of the rake edge). I scored it with a common utility knife, then snipped just the end (about a quarter inch) and then bent it back and forth until it stressed and came apart. I know others prefer not to do this on long pieces. I saw no reason to buy any other tools. It worked well for me. Hope this helps and best of luck with your project. You will be happy any way you go.

|

|

Whiskerbiscuit

Member

|

# Posted: 11 Apr 2023 01:14pm

Reply

In my area standing seam metal roofing (which is the majority of my cabin) was about $3 (CDN) per sq. ft. in 2018, but would of course be higher now. The "agricultural" grade metal roof panels, which use exposed fasteners and a slightly thinner gauge metal were about $1.50 /sq. ft. The flashing and trim pieces probably made up 25% of the total cost of my roof.

One thing I learned is that our local roofing supply store could often custom manufacture metal flashing pieces of better quality and cheaper per foot than what I could buy off the shelf at HomeDepot.

|

|

|