| . 1 . 2 . >> |

| Author |

Message |

fasenuff

Member

|

# Posted: 26 Nov 2010 11:11am - Edited by: fasenuff

Reply

With the number of first timers that come here who have had little or no experience I thought a topic that was full of tips from those who have veen there would be very helpful. Tips for how to to things by yourself or how to do something and save a few dollars and stiil do it right. Also I have learned from others in the past ways of doing things easier than I did before so maybe we all can learn from each other here.

My first tip is how I install a long board or a sheet of siding by my self. When installing a sheet of 4x8 siding I will always run a chaulk line at the bottom of where the siding should go. Then I wll drive 16p nails just below that line so that when I place the siding where it goes I only need one hand to lightly hold it in place or even my shoulder. Makes nailing it so much easier and insures I get it in the right place first time. When putting in floor joists I will nail a short piece of 2x6 on the bottom of the rim joist so that I can set the joist on it while I nail. Also when nailing I only drive the nail in until it is holding the joist or siding in place until I double check that it is in the right place.

What about you? Got a good tip?

|

|

fthurber

Member

|

# Posted: 26 Nov 2010 12:12pm - Edited by: fthurber

Reply

One thing I do is use exterior decking screws instead of nails for all my joinery. It makes it easier (if you do not strip the screw) to undo your construction and makes more secure connections.

All my lumber (except the under flooring which is pressure treated) is bought from the local sawmill as green and rough cut. You cannot beat the price and it looks great. I have to laugh when I see all the ads for various "outlet" or "bargine" or "liquidators" selling lumber at great prices. They still cannot beat the sawmill (except for the 2x3 firring).

|

|

Gary O

Member

|

# Posted: 26 Nov 2010 12:59pm

Reply

When planning a trip to the cabin, or site, make a list of the tools and supplies you'll be needing way before the day you go, then just check it off as you load your truck or trailer. This has saved me a lot of head banging on trees and gnashing of teeth when at the site.

Another (related) thought would be to inventory your job box.

Our place is 240 mi away, and the store is 50 mi from the cabin, so the atmosphere turns a bit blue with colorful verbiage when I discover an empty screw box, or a missing framing square (of which I now have two, from a recent experience).

|

|

Rob_O

|

# Posted: 26 Nov 2010 01:13pm

Reply

A Paslode nailer can help you get 3 days of work done in a 2 day weekend. I bought mine at a pawn shop for $100

To add to what Gary posted, cut and number all your materials before you load it on the trailer. Lay it all out on the driveway, measure twice, make your cuts, tie it all together with ratchet straps and measure again. Make all your reference marks and draw a blueprint with everything numbered. Every hour of work you do at home is an hour saved on the site

|

|

Gary O

Member

|

# Posted: 26 Nov 2010 02:44pm

Reply

Quoting: Rob_O A Paslode nailer

Wow

A cordless nailer...nice

Not to hep on the fuel cells though

Are they rechargable?

|

|

Rob_O

|

# Posted: 26 Nov 2010 04:22pm

Reply

I'm not aware of any way to recharge the fuel cells.

|

|

tony

Member

|

# Posted: 26 Nov 2010 07:04pm

Reply

I have a paslode nailer too..very, very useful ! You can drive a lot of nails on one fuel cell!

|

|

fasenuff

Member

|

# Posted: 26 Nov 2010 08:44pm

Reply

After nailing as many 16p nails as I have recently I envy you guys with the Paslode nailers. A very good investment.

SL I agree that if you can get it the rough cut saw mill lumber looks great. I had thought about using it for board and batten siding but the only mill near me won't sell boards that way. They only cut stuff to make pallets. Sigh......

|

|

|

islandguy

Member

|

# Posted: 26 Nov 2010 08:50pm

Reply

I bought some plastic totes, and designated one each for: the plumbing tote, the all things electrical tote, the painting tote, and so forth. If I had a small plumbing job, the stuff I needed, including the tools, was at my fingertips, needed a small roller and some thinner to paint a window sill?... the paint tote. Before that I spent more time looking for stuff than actually working. I even had a tote designated just for measuring... tape measures, squares, laser level ect.

|

|

bobrok

Member

|

# Posted: 26 Nov 2010 09:27pm

Reply

Add-on to Gary's comment on planning long before you leave. I rented a compressor & floor nailer when I was going to lay flooring. Drove 4 hrs up and found that the nailer gun was missing the spring loader and was useless. Had to drive an hour each way when I finally found a rental store that had one. Check out ur rental tools also.

Bob

|

|

Gary O

Member

|

# Posted: 26 Nov 2010 10:30pm

Reply

Quoting: islandguy Before that I spent more time looking for stuff than actually working

One word;

Pegboard

Yes, I too have job boxes, and totes, but lot'sa pegboard keeps me from diggin' thru 'em, and I know right away if something's missing.

|

|

MikeOnBike

Member

|

# Posted: 27 Nov 2010 12:10am

Reply

Quoting: Gary O One word; Pegboard

Yes! I have it all over my shop in town but I didn't even think about putting it in the shed on the mtn. I was only thinking about shelves. Duh! I'll have to put it along one of the walls in the shed.

|

|

fooboo

Member

|

# Posted: 27 Nov 2010 12:46am

Reply

Keep a set of blueprints in your truck with you at all times while building. If you make any changes to any dimensions while building, mark these on the plan so you have a running "as-built" drawing at all times. This comes in handy when you come across something for sale used, for instance stair railings, or cabinets, etc. You can pull out your plans and make sure that item will fit before you buy it. A good example is: You've drawn your plan to use a 2'6" door for the bathroom and everything is very tight space-wise, and then you come across a brand new prehung 3'0" door for $10. You whip out your plans and do some quick measuring and realize that there is just no way that a 3'0" door will fit - you just saved yourself a lot of heartache by not buying that door.

The number one tip I ever received (or have given) has to be to use precise measurements and keep everything level - especially early on in construction. As you work your way up in the building process, mistakes made in the foundation or flooring will compound themselves by the time you start the roofing.

Keep a running photo log of your progress. Take lots and lots of pictures of everything from every different angle and at every stage of construction. This helps when trying to ask others for help. For instance, Let's say you're looking for some help on buying the parts for your woodstove chimney. You go to the woodstove store and they have everything you could ever want regarding stovepipe etc and a knowledgeable staff and instead of spending 30 minutes answering their questions, you whip out a bunch of photos (and maybe even video) of the framing, insulation, and finish carpentry for where the stovepipe is going to go. In an instant, your stovepipe helper has all the answers they need to recommend the correct passthrough for your chimney. A picture is worth a thousand words sometimes.

If you don't intend to adhere to building codes, well that's fine by me, but at least know what the building code is and WHY it is what it is. Some of them are common sense but others are truly there to save you from dying. If you're going to go against the code, take some time to think out why that code was put in place and then decide what to do. For instance, why do building codes require bedroom windows big enough to climb out of? Because a lot of people have died trying to squeeze through a tiny window in a fire. At least know why the original code was adopted before you break it. Some of the codes, like stair treads and risers, are out of whack for small cabins and don't make sense for a small cabin builder but you should still know why they made those minimum tread and riser dimensions they way they did before you go against it.

If possible, hand pick your lumber at the big box stores, especially if you are in a remote area and are only building on weekends. If others pick your lumber, you might get too many culls. Order a few extra pieces if others are picking and delivering your lumber and don't be afraid to return any crap pieces they send you. If you are working with a sawmill or private lumberyard this won't be that big an issue, but big box stores can be bad at quality control.

Build a map to your place that can be easily followed by others. Test it on someone to see if the directions work for other people and tweak if necessary. Include information like the type of driveway (gravel or asphalt or dirt) and the width of the driveway. Print up a bunch of these and then when you buy something for delivery, you can just hand them a map. This saves a lot of time when you are hiring a roofer, having a propane tank delivered, concrete truck deliveries, etc. If you expect big trucks like concrete, you need to specify turnaround radii and show where a concrete truck can turn around once they finish pumping. Put your phone number on the map so they can call you (or someone who can help them) when they get lost. This might be the phone number of a friend who is in another city but who can guide them if you don't have phone service at your site. This can help prevent failed deliveries and everyone standing around waiting for the truck that never shows up.

Never never never ever ever ever pay a subcontractor until the work is finished AND you have inspected it. Make them prove that they actually paid for the materials they used. You can do this by either making the subcontractor let you talk directly to his supplier, or you can demand that all materials for the job be purchased by you early on in the project. Also make sure they are paying their employees by asking them on the job site if they are getting paid. Either way, you don't want a mechanic's lien on your place down the road so make sure suppliers and workers are paid and never pay a sub in advance. You can make progress payments to your subs as they reach milestones, but never prepay. It is customary to withhold 10% from any sub until you are completely satisfied that the job is done correctly, they given you a written warranty (if appropriate), and that all their suppliers and employees have been paid in full. You should also force any subs you hire to provide you with a certificate of insurance that names you and your jobsite specifically as covered by their insurance. This is also standard practice and should not be a big deal to get it.

That's all I can think of right now - I'm sure I'll think of more later.

|

|

Gary O

Member

|

# Posted: 27 Nov 2010 01:07am

Reply

Quoting: fooboo If possible, hand pick your lumber at the big box stores, especially if you are in a remote area and are only building on weekends

An absolute fact.

An exerpt from my jounal:

Let me lightly touch on a vital principle of buying wood building materials.

PICK, SELECT, GRADE THEM YOURSELF!!!!!

I'd ardently instructed the guy at the lumber yard that I needed them to select these boards, explaining the application and immediate need due to my time available, etc.

However, it seems that the driver mistakenly loaded up the culls, because the only boards that weren't cut from the outer portion of the tree (wane) were warped beyond recognition. So here we were, decision time. Use this stuff, or loose my extended weekend? I caved, but with the new knowledge that I'd have to sheathe over these less than acceptable roof boards since there would be gaps and obvious imperfections.

|

|

fooboo

Member

|

# Posted: 27 Nov 2010 01:23am

Reply

If you are building above grade with a pier foundation, you probably won't put in steps until near the end of the project. You need some way to easily move materials up onto the subfloor as you are building. Consider building a ramp instead of temporary steps. A ramp is easier to navigate when carrying sheets of plywood and you can use a wheelbarrow or cart when performing cleanup.

If you have a sliding glass door in your cabin, situate your ramp at that location so that everyone is entering and exiting the cabin at that wide entrance. If you don't have a sliding glass door, you can situate the ramp where your front door will be and leave out a stud or two where the door will go so that it is wider during construction. You may need to temporarily brace it with a temporary header. Towards the end of the project, you can add in the studs that frame out the entrance and bring it back to the correct opening. The idea is that the easy in and out means you're saving about 15 to 30 seconds every time you enter or exit the cabin with something in your hands and that adds up to a lot of time by the end of the project, plus less chance of injury and less fatigue.

Once you get your subfloor in, you can store your framing lumber underneath the subfloor so it doesn't get wet. You can even decide to put the west wall framing lumber under the west side of the subfloor, and the north framing lumber under the north side, etc. so it's faster when you start building walls.

An even better way is to build a very quick and simple picnic pavilion or carport before you even start your cabin and then store all your lumber underneath that and keep your miter saw there too. After the cabin is finished, you can use the pavilion as a picnic shelter or carport or put some siding on it and make it a barn. A single car carport is usually 20x12 or thereabouts and that makes a great space to store lumber and setup your sawhorses and make all your cuts out of the rain. This structure doesn't even need a floor, a dirt floor is probably sufficient. What you really want is the rain protection.

|

|

Gary O

Member

|

# Posted: 27 Nov 2010 01:08pm

Reply

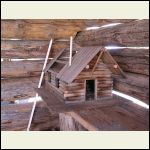

Since I have yet to build from plans other than my quad pad scrawlings, I build a model to help me determine whether or not what I have in my head is doable. It saves a lot of pencil whipping (and erasing) as the transfer from thought to paper gets lost somewhere between my frontal lobe and my elbow..........and I like to cut wood.

1/2" pine ripped to 1/2 x 1/2 makes my 4x4s, and everything works pretty good at an 8-1 scale.

The next cabin w/be 12' x 16', the model shown is actually 18" x 24"

Air driven staples seem to work best

model_2_001.JPG

|

cabin_2_model_002.JP.jpg

|  |  |

|

|

toyota_mdt_tech

Member

|

# Posted: 27 Nov 2010 09:09pm - Edited by: toyota_mdt_tech

Reply

Quoting: fooboo The number one tip I ever received (or have given) has to be to use precise measurements and keep everything level - especially early on in construction. As you work your way up in the building process, mistakes made in the foundation or flooring will compound themselves by the time you start the roofing.

This is so important. In the early stages, one can say "its only a 1/2" off our out of plumb... Stop right there and fix it now. Or soon, you wont be making any square or straight cuts, its all angled,tapered and everything is custom and it will slow you down so fast.

I might add, pull all your measurements from a specific corner. Pick a corner and this is where all your measurements will come from.

For example, on my cabin, we used the NE corner and any wall floor joist, rafters running that direction was pulled starting from that corner. So any measurements for layout going on a east or a west wall, pulled it from the north wall. Any measurements for layout on a north south wall, we pulled them all from the east wall.

Never pull a measurement from a north/south wall from the west wall, only the east. Once this reference point is established, use it for the rest of the build.

Even if you have an interior stub wall starting from the opposite wall and may not even run to the back, pull the measurements from the same spot/wall that you pulled your measurements from, even if the stub all is on the opposite side of the cabin. This will keep all your studs, joist, rafters etc in the right spot. Siding will always end up in the right spot. Also start all your exterior sheating from that same corner. Does this make sense??? I odnt know if I explained it well enough.

I sub'd out my footing/stemwall and hired a professional builder at a cost of $40 to help me frame and sheat it. That was the best investment I ever made. I learned a boat load and co uld easily do it without any help. He also had his own generator, compressor, all the air nailers...

No way would i hand bang all those nails now.

I might add, my pro builder would nail a top and the bottom plate together, but not drive the nail in all the way. Then he would do the framing layout, ie stud spacing, window openings etc and mark his top and bottom plates at the same time. Then he would pry them apart, and nail in the studs, and the marks on top and bottom where perfectly in line.

And flooring, we used 3/4" T&G, we also glued them down. Then we had to use a huge hammer to beat them into place. Glue means no squeaks. But sometimes a squeaking cabin give it that rustic feeling.

|

|

fasenuff

Member

|

# Posted: 28 Nov 2010 07:17am

Reply

One thing that can be helpful is to save all the scrap 2x's at the end of the build. Later when the cabin is up and the cold days have set in those scraps can be very usefulb for starting a fire in the wood stove. Just a couple pieces of 2x4 3" long split up will make starting the fire so much easier and quicker.

They also will have many uses as you fit out the inside. A piece of 2x4 attached to the side of a stud makes a good place to sit a small battery powered light or other things.

I priced my lumber with several suppliers and found I could buy 8' 2x4's cheaper than precut studs and ended up with a bunch of those short pieces that have come in handy for many things. Burning them in a pile in the yard would have been such a waste.

|

|

Gary O

Member

|

# Posted: 28 Nov 2010 12:57pm - Edited by: Gary O

Reply

You are creating something that you'll be using and possibly looking at for a long time.

Take your time. Face it, you'll never be 'done'...................

Savor the moments.

Maintain your sense of humor.

|

|

toyota_mdt_tech

Member

|

# Posted: 29 Nov 2010 09:12am - Edited by: toyota_mdt_tech

Reply

Gary, when I do complete it, I will make up stuff to do. If I was truely finished, I'd feel lost. Probably have to start on another cabin. I will do my final home on the same site as my cabin. Cabin may be a guest shack, tool shed, HAM radio shack....

|

|

Gary O

Member

|

# Posted: 29 Nov 2010 09:42am

Reply

Quoting: toyota_mdt_tech If I was truely finished, I'd feel lost

To wit. I rest my case.

Oh, the excruciating fun and joy of it all.

The name of fasenuff's thread is so befitting;

Tips for easier building....because it's not easy. If it were, more would be doing it.

fasenuff, I don't wish to step on your thread, but the theme (IMO) goes with my philosophy.

An excerpt from my journal;

Why

Because I'm a desperate American!!!!

Just kidding.

In our protective world of sealing ourselves from the environment, peeking out occasionally to view severe weather, running from the porch to the car in the rain, cranking up the A/C in the summer, running on a tread mill, going nowhere fast (like gargantuan mice) to remove the lard from our guts and butts, because we have striven to garner a vocation of ease, but have kept the same eating regimen that we had when we loaded trucks for a living, I have cultivated a thirst for adversity of my surroundings. Nature.

Also, in our electronic world of turning on switches, pressing buttons, setting thermostats, and living vicariously thru the TV and computer, I have a very strong desire to build something of my own, something tangible, something I have carved, not something I made with the poke of a button.

Yes, I have a shop, and if God cripples me between now and the completion of my crude dwelling, then I'll be content with taking $100 worth of veneer and making a $30 end table.

Our techno world is so filled with information and options it boggles my mind.

We had a new heat pump installed a couple years ago, and to this day, for the life of me, I cannot figure out the new 'improved' digital thermostat. Maybe I need to be able to program the setting for the entire year, including vacations, holidays, time of day, daylight/standard time (the new one), weather, and any other event I should think about, in the name of conservation, and operating the heat pump to its utmost efficiency. But, I'm a simple man. I just want on/off with a max/min setting.

So, the wife and I sneak up on this device from Satan, and carefully, c-a-r-e-f-u-l-l-y poke the two buttons of which we have operating knowledge (I think).

Once I (really I think it was her) poked one of the 13 other buttons. It took the rest of the evening to get the thing turned off. Actually, I think thermostats would be good subject matter for the next twilight zone movie.

I shopped for a simple watch the other day, and found one most suitable. One stem, Analog. But I do have to re-set the days every month.

It's OK.

Ten bucks.

I cringe every time daylight/standard time changes (the new ones) come around. All the clocks on all the time saving devices (or anything that has a plug) and all their individual digital settings, and thermostats with all their individual digital settings, need to be changed. The Atomic clocks, with minds of their own, need to be changed twice as much! Another twilight zone for sure. Poor bastards that have Atomic thermostats.............

I even take my watch off on Friday afternoon and don't put it back on until Monday morning. Why chase the clock when you don't have to.

So, I feel the need to trade softship for a bit of natural hardship.

No, I'm not kidding myself. We all have read or scanned thru the books, with pictorials of snug little cabins, fire places glowing, old tin cups on the hand hewn table, and coffee pot hanging over the fire, written about an individual that escaped to a remote spot in Alaska or Canada, and hewed his own cabin out of trees, moss, rock, and squirrel skins, all accomplished with his raw boned, gnarly hands in three days. Later, the following week, he clawed at slabs of iron ore to forge a saw and axe.......I'm not him.

These guys usually tend to be a bit skittish around humans. That's one reason they are out there. I just want to get back in touch with creation.

We will still be on the grid, and computer usage will not be limited, but stepping out the door into the great outdoors has huge drawing power for me.

The wife and I marveled at the various birds that happened by while we rested between tasks. We even saw a weasel darting thru some fallen logs.

Yes, there will be a lot of work, just to sustain a decent mode of living, but in comparison to what?

|

|

tony

Member

|

# Posted: 29 Nov 2010 11:03am

Reply

Quoting: Gary O No, I'm not kidding myself. We all have read or scanned thru the books, with pictorials of snug little cabins, fire places glowing, old tin cups on the hand hewn table, and coffee pot hanging over the fire, written about an individual that escaped to a remote spot in Alaska or Canada, and hewed his own cabin out of trees, moss, rock, and squirrel skins, all accomplished with his raw boned, gnarly hands in three days. Later, the following week, he clawed at slabs of iron ore to forge a saw and axe....

LOL!

|

|

hattie

Member

|

# Posted: 29 Nov 2010 12:32pm

Reply

Hey Gary O, you are quite talented....I really enjoyed reading that....Keep it coming. *S*

|

|

Gary O

Member

|

# Posted: 29 Nov 2010 01:01pm

Reply

Yeah, if I don't watch out, I'll be submitting the whole darn thing in this forum (in bits and pieces).

But ,geez, thank you very much, Hattie!

Finally some feed back, and from a bona fide author!

.....and now, back to the rest of the 'Tips for easier Building' story

|

|

fpw

Member

|

# Posted: 30 Nov 2010 08:42am

Reply

Mechanical Advantage...learn to rig. Think about what you are doing; make it easier. You can accomplish quite a bit by yourself. Design equipment to make things easier on the back. The further you get away from the main roads, the more important rigging becomes.

Rigging the ridge pole...

http://peelinglogs.blogspot.com/2009/09/rigging-ridge-pole.html

Setting up a small portable gin pole...

http://peelinglogs.blogspot.com/2009/04/gin-pole-set-up.html

Using a log arch...

http://peelinglogs.blogspot.com/2010/03/working-log-arch.html

I use the Army Field Manual (FM 5-125) for rigging quite frequently, very good information. Manual can be found at the following URL:

http://www.enlisted.info/field-manuals/fm-5-125-rigging-techniques-procedures-and-app lications.shtml

|

|

CJHames

Member

|

# Posted: 2 Jan 2011 06:42pm

Reply

Very cool idea, thanks for sharing Gary O.

|

|

CJHames

Member

|

# Posted: 2 Jan 2011 07:11pm

Reply

Quoting: Gary O In our protective world of sealing ourselves from the environment, peeking out occasionally to view severe weather, running from the porch to the car in the rain, cranking up the A/C in the summer, running on a tread mill, going nowhere fast (like gargantuan mice) to remove the lard from our guts and butts, because we have striven to garner a vocation of ease, but have kept the same eating regimen that we had when we loaded trucks for a living, I have cultivated a thirst for adversity of my surroundings. Nature.

Beautiful stuff, Gary. Me thinks there may be a novel in there somewhere.

|

|

elkdiebymybow

Member

|

# Posted: 17 Jan 2011 02:58pm

Reply

Plan, plan, plan. Draft a set of working docs and/or build a model. I built a simple model to scale and then made a few minor changes while constructing. Think about what you are going to do and all the tools and resources needed to complete the task and then check your list a couple of times. Bring more than you think you'll need! Especially cold beer. Lots of cold beer!

This should be a fun experience so remember to relax and have a great time! A friend or two who know what they are doing are a huge help. I spent numerous hours building by myself and really enjoyed the alone time.

Cabin and model

|

Cabin in a Cabin

|  |  |

|

|

PlicketyCat

Member

|

# Posted: 17 Jan 2011 06:43pm

Reply

I didn't have space in the tent to build a stick model beforehand, so I opted to build a 3D computer model instead (I used Google's free SketchUp program). But definitely build some sort of model whether it's stick or electronic because isometric drawings really don't show you areas where you're going to run into construction issues... like not having enough clearance to turn or attach something or the order you need to install something so another piece can be fitted properly.

Definitely purchase and wear a good tool belt!! Preferably one with adjustable pockets and accessories that you can customize to work just the way you do. I can't tell you how much time I've wasted having to go hunt for things or passing up nails, etc to my DH because he refuses to wear his :) Mine may weigh 20 lbs some days, but I've never been caught 14' up the ladder needing something either LOL!

Get a good chalk line, one that has a good attachment point, and then get the best and brightest chalk you can find. I skimped once and bought some bulk red chalk... it clumped up, didn't leave thick-crisp lines, and I could hardly see the color on some of the darker wood. Now I get bright blue or optic green... haven't lost a line since. Chalk lines are a million times better-faster than using a straight edge for marking long freehand rip cuts with a circular saw, and for marking square/level course lines for siding/shingles/underlayment/tile.

Consider a two-faced post level that reads level & plumb on 2 faces and the corner at the same time for studs and posts... nothing bites worse than toe-nailing in only to find that you're out of plumb on the other direction. Doh!!

Sometimes it's better to use a Sharpee marker than a pencil... carry both, and get little retractable leashes for them so they're always attached to your person.

|

|

Gary O

Member

|

# Posted: 21 Jan 2011 09:32am

Reply

Yes!

I post level....I've needed that for years!

Never gave retractable leashes a thought.

I've got two on all my fishing vests, but what could be a better application than when atop a ladder, and the dang pencil is on the ground ('cause it fell outta the tool pouch when grabbing for it while holding a board in place).....

well played P-Cat

Gary O'

|

|

| . 1 . 2 . >> |