| . 1 . 2 . >> |

| Author |

Message |

revid

Member

|

# Posted: 1 Apr 2016 06:46am

Reply

Anyone know of any sites or have any pointers for someone(me) to help with building a butt and pass method log cabin or wouldn't mind answering a few questions on the subject?

|

|

redagain

Member

|

# Posted: 1 Apr 2016 07:26am

Reply

Be happy to...built this small log lake cabin for my family weekends up north....used a square tenon notch ends...its butt and pass...be happy to share the info

|

|

FishHog

Member

|

# Posted: 1 Apr 2016 09:03am

Reply

beautiful work redagain

|

|

toyota_mdt_tech

Member

|

# Posted: 1 Apr 2016 10:18am

Reply

Quoting: revid Anyone know of any sites or have any pointers for someone(me) to help with building a butt and pass method log cabin or wouldn't mind answering a few questions on the subject?

Log Home Builders Assoc specializes in just that method, sign up for their 3 day class, it covers it all including how to obtain logs from National Forest etc. They have that method of building down to a science. I may still go to one, one day. Even if I don't build a log home.

|

|

revid

Member

|

# Posted: 1 Apr 2016 09:04pm

Reply

I know the site but I am up on the east coast of Canada.No where near a course.

|

|

revid

Member

|

# Posted: 1 Apr 2016 09:18pm

Reply

redagain

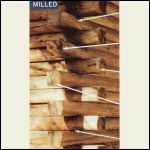

thanks redagain nice job! that don't exactly look like the butt and pass method I am used to seeing.I guess theres probably different versions .Heres a couple of pics of what I am trying to do from the internet.

butt_and_pass.jpg

|

milled.jpg

|  |  |

|

|

Don_P

Member

|

# Posted: 1 Apr 2016 10:05pm

Reply

What are your questions?

|

|

rockies

Member

|

# Posted: 1 Apr 2016 10:15pm

Reply

Wouldn't every horizontal surface protruding beyond the corner be susceptible to rot?

|

|

|

toyota_mdt_tech

Member

|

# Posted: 1 Apr 2016 10:37pm

Reply

Not if the wood is always treated and enough overhang. Wood preserve, treatments, cleaning is a big task on a log home. I wouldnt go too long on them (extensions) like the one pictured above (proportional to log size) but that isnt a log home, its a dowel pin home.

|

|

skootamattaschmidty

Member

|

# Posted: 1 Apr 2016 11:41pm

Reply

Redagain your place is amazing! I love it! Very nice.

I built a log sauna using a scribed fit and notched corners, not butt and pass but I'm sure similar techniques. I read Robert Chambers' book "Log Cabin Construction Manual." It was very helpful and had information on the various techniques.

I'm not sure if I can help with any questions you have but post them and if I can help I will.

|

|

skootamattaschmidty

Member

|

# Posted: 1 Apr 2016 11:42pm

Reply

My sauna

|

|

bldginsp

Member

|

# Posted: 1 Apr 2016 11:42pm

Reply

Best book I've seen on log construction is Robert Chamber's "Log Construction Manual"

|

|

revid

Member

|

# Posted: 2 Apr 2016 05:33am

Reply

Thanks guys.just wondering about how to butt the logs in the corners so they are tight? They say to use rebar and drill hole in top log but not the bottom one, you must have to point/sharpen the rebar? All that rebar so t split the logs? Iam using 8" logs flatten on top and bottom, what size rebar?have a few more but that's enough for now.Thanks

|

|

revid

Member

|

# Posted: 2 Apr 2016 05:37am

Reply

skootamattaschmidty, nice job!!

|

|

Don_P

Member

|

# Posted: 2 Apr 2016 07:52am

Reply

I've done several flat on flat log homes in the Wilderness, Greatwood, etc style before they went half log. They were typically notch and pass, by which I mean, when looked at from above, the passing log had a female V cut into the passing log and the butting log had a corresponding V point that slid into the V notch. The Prazi beam saw shown in bldginsp's thread is handy for those cuts.

Those companies typically used 12" landscape spikes into 8" thick logs. We quickly switched to using 3/8x10 lags countersunk into 1/2" prebored with 1" countersunk holes. The upper log got the prebore and counterbore, the lower log was run into without any bore (3/8" is the max dia non prebored fastener in the NDS, if you prebore the lower log you can go up in dia) The lags can pull a slight rocking chair log down tight where with spikes the logs would just rock and pull fasteners. Rebar is going to be the same... you can hold things together but not really draw them down tight. Some companies have gone to log hogs, oly screws or similar 1/4" hardened steel fasteners they require no prebores but don't have as much pull down as a lag so when using them we kept a few hundred lags handy... a fastener every 32" or so, they add up fast. If you followed that, the upper log can slide down freely. Next advance was 1/2" allthread from bottom to top cinched down. It is a good idea but don't think you can stack and draw down an entire wall with these. A few companies put springs on the allthread to help keep tension, largely about the equivalent of putting an extra fly on the wall.

A flattened log does not dry flat. Wood science... radial shrinkage, a vertical line drawn from flat to flat through the heart, shrinks about half as much as tangential grain... the vertical line drawn from flat to flat at the outer edges. The flats end up convex, pregnant. When dry the logs end up bearing in the centers of the flats and gapped on the inside and outside, not what I wanted. We ran a power planer down the center of the underside flat to relieve that area and put the bearing on the outer edges. This also leaves a place to run sealing foam tape,,, which has dimension and should not be crushed to zero if you want it to recover and do its job.

Place the log you are setting on the row below and notice how it sits on that row. Never leave a water catching ledge on that row, scribe the offending projections, remove the new log, drawknife off the offending projection and then set and fasten the new log. Drip edges not water catching ledges.

More than enough for now

|

|

skootamattaschmidty

Member

|

# Posted: 2 Apr 2016 08:20am

Reply

I used 12"" spikes on my logs. Sine it was a scribed fit, the did sit flat on the row below. If using flat logs like Don said I like the idea of the lags to pull them tight.

|

|

redagain

Member

|

# Posted: 2 Apr 2016 05:07pm

Reply

Nice job skoot..very nice. Revid...this was my first log cabin...the book i found most useful was "Building the Alaska log home" it really helped me alot. I used sections of rebar in the corners and along side door and window openings..drilling holes so that the rebar almost falls in..too tight and the logs cant shrink and settle together...try the book..great read anyways...as far as butt and pass...im refering to the method of stacking with big and small ends of logs...since they are different diameter from one end to the other. When we got to cap log height..we were within a 1/2' on all four corners.

|

|

Malamute

Member

|

# Posted: 2 Apr 2016 07:59pm - Edited by: Malamute

Reply

Quoting: redagain ...built this small log lake cabin for my family weekends up north....used a square tenon notch ends...its butt and pass...

The usual butt and pass is each log blind butts against another laid in the same level. Yours isn't really butt and pass. The flat lapped corners are really pretty easy compared to round or saddle notches, and I think a big improvement over true butt and pass, in looks and corner strength/tightness.

I used rebar for around doors and windows on one, then started using smooth steel rod so it would slip easier when settling. I use large spikes in the corner joints (round or saddle notch corners) with the hole in the upper log pre-drilled and the head counter sunk. Its easier if you have a steel tool made like a sideways letter T, using the tail as a handle, the cross part as the punch with a 2 lb hammer (small sledge) to drive the spikes in. Think I used 5/8" rod for the cross, 1/2" for the handle or tail.

I'll add that most think of log work as a sort of mystical, special art form done only by master craftsmen. In truth, most old log work on the frontiers was done of necessity by people having only a vague or general idea of what needed to be done. There were indeed master craftsmen that built some log structures, and there are some of those people today, but log work isn't rocket surgery, and can be done by about anyone with just the desire to do it. I think many are unnecessarily intimidated by it. Theres many simple ways of doing it that result in quite useable cabins and don't require education or special techniques. I built my first one after looking at a few old ones, some descriptions in books, and took a single picture I liked* and started building. o plans or anything, just the concept and some basic tools.

* My inspiration picture https://libraries.mit.edu/150books/files/2011/03/1947-cabin1.jpg

|

|

Don_P

Member

|

# Posted: 2 Apr 2016 08:15pm - Edited by: Don_P

Reply

Attached is another way to do a corner. These were typical 6x8 kit logs but the method works for any timber. I got some 10x10's and routed grooves to insert tennoned log ends into, then I capped it with a 10x10 mortised tie beam. This method is similar to how the old Hudson Bay company log buildings were constructed.

Edit, third shot is an 1847 white oak cabin with an Appalachian saddle notch corner (Foxfire 1 has details) and the 1865 red oak timberframe including the low fired brick noggin. Termites destroyed the red oak frame but had a tougher time with the white which we did restore.

|

|

Malamute

Member

|

# Posted: 2 Apr 2016 08:23pm - Edited by: Malamute

Reply

Theres many different ways to build with log. That's a good example.

On the little 14x18 cabin Im currently living in, I used leftover logs from another cabin. To maximize inside space, I used V plank corners made from rough cut (full dimension) lumber. So far, in 10 years its been OK. I laid the first course with saddle notched corners, then set the V planks on them.

|

|

Just

Member

|

# Posted: 2 Apr 2016 08:40pm

Reply

Very nice looks good and less complicated

|

|

Malamute

Member

|

# Posted: 2 Apr 2016 08:44pm

Reply

I plan to box the corners in with slab wood. They will look like somewhat like vertical logs.

Being the sort to overbuild, I also had steel corner braces made for top and bottom of each corner, lag screwed into each wall and top or bottom of each corner.

|

|

toyota_mdt_tech

Member

|

# Posted: 2 Apr 2016 09:23pm - Edited by: toyota_mdt_tech

Reply

I always thought to take a large round long set on it ends (vertical) and then maybe flatted the sides so you can but in a horizontal log. Now there would be shrinkage on the log and you'd get a gap, but maybe the tenon and a groove in the corner log. The advantage to this system would be the ease of replacing a log down the road if one ever rotted out.

Of course, all vertical log walls is another option, but just doesnt feel like a normal log home inside IMHO.

|

|

revid

Member

|

# Posted: 3 Apr 2016 07:05am

Reply

thanks guys for the info,slot of interesting read.Going to try and find a copy of that book Redagain.I like that corner Toyota but guessing a lot of lifting up high in order to slid each log down the the groove.Wondering how to make a jig for my powersaw to cut the tenon and groove?Don't like vertical logs cause IMHO they don't look like a "normal" cabin either. I can't find that plazi beam saw thread,sounds interesting. The other thing is,I was planning on building 24x28' cabin.The longest my logs are is 20',so I will have to make joins.I was hoping to avoid this as much as possible but will have to make some.Where my inside walls meet and intersect the outside walls i am hoping to use alot of the shorter butt logs here . I guess where the logs joins together there will be some gaps develop.Thanks guys,my head is buzzing now with more ideas,lol.

|

|

toyota_mdt_tech

Member

|

# Posted: 3 Apr 2016 12:47pm

Reply

Revid, a tennon would be optional. All the ones I have seen that way with vertical corner log was just wall logs lag bolted into it. Much easier to set up. The tennon was just me thinking out loud to avoid gaps, allows shrinking when drying out etc.

|

|

Topper

Member

|

# Posted: 3 Apr 2016 10:34pm

Reply

Cache Lake Country!

Henry B. Kane is my favorite illustrator.

|

|

Don_P

Member

|

# Posted: 3 Apr 2016 10:52pm

Reply

This is the thread with the Prazi beam saw... and ZZ Top's roadies, pretty sweet rafter notching as well, well thought out;

http://www.small-cabin.com/forum/6_3673_0.html

I never just butt timbers together, there's your air leak.

Another good book that goes into the vertical log posts with horizontal infill logs is "The Craft Of Modular Post and Beam" oops my copy is loaned out, can't recall the author at the moment.

|

|

AK Seabee

Member

|

# Posted: 3 Apr 2016 11:14pm

Reply

I spent a couple summers building large log homes. The logs were 20 plus inches and were kits from BC Canada.They were scribe fit and drybut still settled about 1/2 an inch per foot of log. In addition to gravity keeping the logs tight we drilled and used 3/4 all thread with a lock nut on the top log and spring loaded locking device below the bottom log.

As the logs settle the all thread and tightening device keep the logs tight where spikes act to keep the logs in place and dont allow them to settle.

Also, in doors and windows we notched the logs and placed the angle iron attached to 2 x 12's in the openings. We then attached the doors and windows to the 2 x 12's leaving room at the top for settling.

Good luck with your build!

|

|

Malamute

Member

|

# Posted: 4 Apr 2016 01:16am - Edited by: Malamute

Reply

Quoting: AK Seabee Also, in doors and windows we notched the logs and placed the angle iron attached to 2 x 12's in the openings. We then attached the doors and windows to the 2 x 12's leaving room at the top for settling.

I groove the ends of the logs in the door and window openings and inlet a 2x4 into them on edge (the skinny side exposed for the frame to attach to). Need to leave enough room for the logs to settle down on them and the 2x4 not hold the logs up. The door and window frame were attached to the 2x4 splines. Its interesting chain saw work. Plunge cuts into the log ends, several kerfs, break out chips, and clean up with the tip of the bar. The little saws are good at this. Besides giving a little room in smaller windows, they are small enough to manhandle in tight spaces to avoid kickback. You pretty much have to get in the window space with the saw to get the cuts square and see what youre doing.

When using spikes, I drilled the upper log so the spike shaft wasn't tight, and countersunk the heads so the logs could settle.

I was building smaller places, and the logs were all dead standing, dry trees in a very dry climate. I left settling space, but it never amounted to much compared to wetter logs. The foam pipe insulation makes good compressible backer rod to chink over above doors and windows.

I also used allthread through the walls. I didn't go all the way down, the longest drill bit extension I had was 6'. I left the nut on the lower end exposed and snugged them up a year or two later then chinked over them. I think the most I got out of them was around 3/4" of tightening.

|

|

Nirky

Member

|

# Posted: 4 Apr 2016 07:32am - Edited by: Nirky

Reply

http://community.loghomebuilders.org/forumdisplay.php?37-General-discussion-about-log -homes-and-cabins&s=092f42afe1d932ec9eb5730638fbdc2a

This is a community of people who have actually built a butt & pass log home. They know the methods, tools, and potential problem areas to watch out for.

|

|

| . 1 . 2 . >> |