|

| Author |

Message |

bnichols1961

Member

|

# Posted: 20 Mar 2016 03:02pm

Reply

Can anyone give me some advice here

I am going to be building a Log Cabin building for a shop (24x18)

using logs I take down from out Property so trees will not be dry and i am not removing bark from trees

once construction is up what is the best method to chink between the logs using Mortar of something that wont cost me an arm and a leg

|

|

Don_P

Member

|

# Posted: 20 Mar 2016 04:20pm

Reply

Don't waste your time chinking it if you aren't going to debark it. The bark beetles will remove the bark and the chinking in short order.

|

|

bldginsp

Member

|

# Posted: 20 Mar 2016 05:35pm - Edited by: bldginsp

Reply

You really need to debark, time consuming as it is. Don is right about the beetles but also the remaining bark will gradually begin to peel and look bad, as well as promoting rot by holding moisture.

The whole thing about chinking is flexibility, because your logs will shrink as they dry, but even after they dry to the extent that they will, they will expand and shrink enough with yearly moisture variations to put cracks in any brittle, hard chinking.

There are amazing chinking products for sale that fix the problem, but cost a lot of money. You could just use a simple mortar mix, or a daub mix which is a simple lime/straw mix, and then be prepared to do some sealing later after everything settles in.

One poster here, named Sarahax I think, had a log cabin built in southern England by Polish builders using their traditional techniques. For chinking, one of the Poles actually went to Poland to get shavings of a particular type of tree which they balled together and stuffed in for chinking. That particular material had what they considered to be best characteristics of flexibility and workability. I think they used the shavings alone with no additives.

For a garage I'd just try balling up straw straight off the bale and cram it in there with a stick. You could add a small amount of water proof woodworkers glue (aliphatic resin, common yellow) to each ball, just enough to make it tacky not soggy. That glue retains some flexibility. Never tried this- just a guess.

|

|

Smawgunner

Member

|

# Posted: 20 Mar 2016 07:51pm

Reply

We chinked our logs on the inside with type S mortar. The logs are very dry and over 100 years old though. We looked into Permachink but WAAAAAAAAY too expensive. You could try mortar and see what happens. You'd just have to caulk or patch the cracks. Use a stucco mesh behind it and make sure the chinking isn't but a 1/2 inch thick at most. Good luck!

|

|

toyota_mdt_tech

Member

|

# Posted: 20 Mar 2016 08:43pm

Reply

I agree with everyone in here. Debark them. First, cut the trees in the winter, you wont have the sap leeching out. You can debark them by using a spud bar and a pressure washer too. I knew a guy who was a member of the log home builders assoc and this is how he debarked his logs for his home. I guess it went pretty fast. Once logs are all in place, then let them dry, shrink etc. Chink afterwards when settling/drying is all done. If you want to save time, then use the "butt/pass" method to offset time spent on debarking it. I like the looks of that white stuff you pump in, but hears is spendy.

When I was a kid, my dag and all us kids built a log toolshed. We did the typical saddle notch and fit all logs in real tight, so chinking was minimal. We used peeled cedar bark and packed it in tight. Cost was free.

|

|

MtnDon

Member

|

# Posted: 20 Mar 2016 09:51pm

Reply

Trees have sap in the wood all year long, about the same amount no matter the season. Lots of references to this on the forestry forum and woodweb.com. A very common misconception. There are certain other seasonal issues but a live tree contains moisture. Period.

|

|

Don_P

Member

|

# Posted: 20 Mar 2016 10:54pm - Edited by: Don_P

Reply

More than most want to know  , conifers keep their needles year round for a reason, if the sap can flow it is photosynthesizing. Well, scrape the twig bark back on a cherry, or many hardwoods and you'll hit a green chlorophyll layer, the winter solar collector. They are definitely idling, this isn't a productive time, winter would pull too much moisture from the leaves for the moisture and light available so the tree drops them, but it doesn't drain down or stop. Their cells cannot survive an embolism any more than ours, they must be full. Sap antifreeze properties define the forest as you drive north. Conifer needles transpire less and have a waxy cuticle to help protect them, so they hold their needles, and they input through the young bark as well. I don't know but suspect that the starch/sugar content varies through the seasons, but we have bugs and fungi that love both so don't see an advantage there. , conifers keep their needles year round for a reason, if the sap can flow it is photosynthesizing. Well, scrape the twig bark back on a cherry, or many hardwoods and you'll hit a green chlorophyll layer, the winter solar collector. They are definitely idling, this isn't a productive time, winter would pull too much moisture from the leaves for the moisture and light available so the tree drops them, but it doesn't drain down or stop. Their cells cannot survive an embolism any more than ours, they must be full. Sap antifreeze properties define the forest as you drive north. Conifer needles transpire less and have a waxy cuticle to help protect them, so they hold their needles, and they input through the young bark as well. I don't know but suspect that the starch/sugar content varies through the seasons, but we have bugs and fungi that love both so don't see an advantage there.

Our trees just woke up for the spring, the sap flow is strong and full of sugar, converted from stored starch... the third molecule a tree can make from those building blocks is cellulose. Anyway, in a month or two the bark will slip. As the cambium layer rapidly divides to form the lighter earlywood growth ring the bark is loose and easily peeled. I can roll a poplar log right out of it's skin at the right time. This is also the time of year of bugs and fungus... that is the real reason for winter cutting. It is easy to peel through spring and early summer but the borers and bluestain work fast as it warms up.

|

|

Jebediah

Member

|

# Posted: 21 Mar 2016 07:04am

Reply

Bark left on.....some people like the look

120photos2012017.jpg

|

images5H0HS7IM.jpg

|

Log_siding_3.jpg

|  |

|

|

|

Steve_S

Member

|

# Posted: 21 Mar 2016 08:22am

Reply

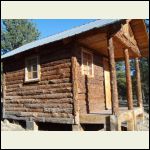

The type of chinking and method of installation is dependent on the method that you are using to build with. For example, if your using a Butt & Pass method, the spacing between your timbers will be minimal and shrinkage / shifting also minimized. An example of that posted by Jebediah.

As other's have mentioned... de-bark ! Bark's only purpose is to house bugs, most of which are happy to feast on the wood and live high & dry while doing so.

It would likely also be prudent to at least "treat" your bottom 2' of logs with a Borate Solution to further enhance the bug repellency. 2 REF articles below: borax.com wood-protection-and-biocides. and askthebuilder.com

|

|

skootamattaschmidty

Member

|

# Posted: 21 Mar 2016 08:51am

Reply

Although more time consuming during the build, a Scribed fit requires no chinking which may actually save time in the long run. Especially when you factor ongoing maintenance. Definitely de-bark. A good draw knife makes easy work of it. Plan a good overhang with your roof to keep the logs dry and it should last you a long time.

|

|

bldginsp

Member

|

# Posted: 21 Mar 2016 02:11pm

Reply

Even with a scribed fit most log builders will put in a gasket of sorts to avoid drafts- I think they make a roll out of some soft material that you lay down like tape. Might be butyl

|

|

skootamattaschmidty

Member

|

# Posted: 21 Mar 2016 04:03pm

Reply

Some use foam insulation that is on a roll and staple it to the log prior to setting in place. I used fiberglass when building mine.

|

|

creeky

Member

|

# Posted: 21 Mar 2016 08:47pm

Reply

Couple years back I talked with a graduate of a wood log and antique building program: he recommended, and showed me examples of, his technique.

He spray foam insulated between the logs. Fast. Insulated. Flexible. And then chinked over the spray foam. This protected the foam and gave the traditional appearance.

He said the advantages were savings on chinking material and time. He said it was a very quick technique.

I don't remember what kind of chinking he used. It was grey. Not concrete. But that sort of idea.

Good luck.

|

|

Don_P

Member

|

# Posted: 21 Mar 2016 11:51pm

Reply

I've used the white beadboard type foam, EPS, to fill the bulk of the gap and sprayfoam to lock it in place. A small flexible Japanese saw cleans up the sprayfoam nicely. Then one of the synthetic chinks over that. There are also a number of backer foams, grip strip is a nice one. The blue and pink foams, XPS, are supposed to cause bubbling trouble... a good idea to talk to the supplier about how you intend to do it. All of those are pricey.

|

|

bnichols1961

Member

|

# Posted: 23 Mar 2016 01:31pm

Reply

i do like the Bark left on so that is what i am doing - I like the look of your building did you use any chinking or just the logs down so there was no gap

|

|

Virginia Highlander

Member

|

# Posted: 23 Mar 2016 09:04pm

Reply

We used a chainsaw attachment called a log wizard.It makes skinning the logs a breeze. We also are using a chinking mixture of Portland cement, sand and lime in our cabin build.

IMG_20160220_122549..jpg

|

IMG_20160220_132308..jpg

|  |  |

|

|

MtnDon

Member

|

# Posted: 23 Mar 2016 09:16pm

Reply

Quoting: bnichols1961 i do like the Bark left on so that is what i am doing -

Every old log or log section that we've left bark on has had the bark come loose after a year or so. Some sooner than others. Some later... just saying...

|

|

Don_P

Member

|

# Posted: 23 Mar 2016 09:49pm

Reply

VA Highlander. when it is thumbprint hard try using a well wrung out soft sponge to smooth/blend and bring out the sand texture... I like the effect anyway. I generally did 2 coats over lath wire nailed in the gaps, a fast scratch coat and then a final coat. Seems to help with cracking.

|

|

Jebediah

Member

|

# Posted: 24 Mar 2016 07:15am

Reply

Quoting: MtnDon Every old log or log section that we've left bark on has had the bark come loose after a year or so

The homes and out buildings I have seen made of cedar logs with the bark left on will come off, but people nail and wire the bark to the log... The cedar has to be cut late Oct- Nov for the best bark adhesion. There is a video on utube of an abandoned log mansion in states, I think in New York, built in this manner, I was surprised to see the amount of work they went through to wire the bark to the logs...I was watching a video on metal detecting and came across the video, can't locate it now....

|

|

Virginia Highlander

Member

|

# Posted: 24 Mar 2016 07:45am

Reply

Thanks Don_P, this is definitely trial and error. I am going to go back over the sections with a second layer. I'll try the sponge trick for the finished look. we are using closed cell pipe insulation as backer rod and galvanized finish nails to give the mortar mix something to hold to.

|

|

|