|

| Author |

Message |

thbarnet

Member

|

# Posted: 27 Apr 2015 09:31pm

Reply

Hey,

first time poster here.

I've gotten permission to build a cabin on a remote island off the northwest coast of BC (my grandfathers land).

I want to build a pier and beam shed roof cabin with a loft section. I want it to be 18ft high, and 14 by 16.

This is basically exactly the cabin I want (minus timber frame, i figure that is probably pretty hard for a beginner) http://humble-homes.com/scott-newkirks-new-york-cabin-woods/

although, there the nearest neighbor has a homesteading cabin with an alaskan mill, and there's cedar tree's everywhere. But then, I would have to build with green wood, and I hear that's no good.

any help would be much appreciated!

Can I frame walls to do this without having any load bearing walls in the cabin? Or do I have to do a timber frame?

And if anyone has any plans or anything for something like this, that would be amazing!

|

|

rockies

Member

|

# Posted: 27 Apr 2015 09:43pm

Reply

No, it's not difficult, especially if you pre-cut all the materials to length and gather the lumber into labeled bundles before you head out to the land (one bundle is west wall, one is east, etc). That way you're not cutting anything at the site, and you know it all fits together.

Usually the most difficult places to insulate in a cabin like this are the floor and ceiling. You might want to look at 10 inch thick Structural Insulated Panels for the cabin floor and roof. The floor panels would rest on foundation beams and they are structure, insulation and vapor barrier all in one. You would not need many with that small size of cabin. Most likely the foundation would be piers.

The roof panels would just screw into traditional 2x6 walls. The main floor walls would be 8' high, about another 1 foot for a loft floor, and 8' on top of the loft floor for the front (south?) loft wall sloping back down to about 2 to 4 feet for the loft wall on the north side.

Do you want an indoor bathroom, running water, electricity?

|

|

thbarnet

Member

|

# Posted: 27 Apr 2015 09:51pm

Reply

nope, nothing like that. Just a basic cabin with a woodstove. I understand I would have to build an extra pier where the woodstove would go.

Also, would the two studded walls stacked on top of each other be structurally sound? would I need to put a support post beneath the loft? Or would floor joists across 14ft be good enough?

Also, the 18ft portion of the cabin is the one facing south, and naturally the one I want with the most windows. Is there some sort of limit where the windows take away the structural integrity of the walls?

And as I mentioned before, I have access to a mill out there, and I'm actually pretty good with a chainsaw/falling, if I were to season WRC for 3 weeks to 1 month, would that be ok to build with it?

Thanks for the quick reply!

|

|

rockies

Member

|

# Posted: 27 Apr 2015 10:33pm

Reply

You will probably need to put a post in the center of the room to support the loft. That's not a bad thing, since it will add a lot of stiffness to your floor. You do have to be careful about the number and size of windows across the front since the more wall you remove the less bracing you have against wind. People always think about snow load, but they hardly ever think about wind forces, and since your cabin will be tall and thin, the more cabin wall the better.

If you aren't planning on using SIPS for your floor, I would definitely use them for your roof. Roofs in a cathedral ceiling design (such as this) are very difficult to insulate since there is not much depth in the roof to allow for insulation and an air channel above it. A nice thick sandwich of foam and osb plywood sheathing makes putting on a roof very fast, and once it's on it's easy to finish.

If you had a couple of friends helping you could probably get the shell up and enclosed in a month.

|

|

Don_P

Member

|

# Posted: 27 Apr 2015 11:17pm - Edited by: Don_P

Reply

I was typing slow, rockies hit many of the points below;

Anything you get out of the wood moisturewise before you use it is a good thing. That won't get timbers dry enough to begin shrinking...WRC has the lowest fiber saturation point of any wood that I know of, it doesn't even begin shrinking till it's down around 19%, but it also has pretty low shrinkage to begin with. Longwinded way of saying your call on whether to use it green. Structurally it would be fine, fit and finish potentially suffers when using green timbers.

18' tall plus piers x 14' deep on a remote island off the coast, a good bit taller than wide. I'd charm an engineer somewhere. His south face would not meet prescriptive wind codes. To do that wall correctly I suspect it needs to be a rigid steel frame. If you can handle at least 16" wide wall sections in the corners and around the middle you can google "portal frame" to get some design links from apa on how to design it using conventional materials.

Pier and beam as typically built is a very weak foundation, it is really a "soft story". With that in mind think about using the same portal frame methods when building a pier and beam type foundation.

With what you have I think I'd frame the exterior walls with 2x6 and frame in beam pockets to insert heavy timber loft beams into. From there you could look at corner and loft posts up to roof beams... you can really pick any of several levels of how much heavy timber to use.

|

|

thbarnet

Member

|

# Posted: 27 Apr 2015 11:44pm

Reply

It's called porcher island just off the coast where I live in Prince Rupert. It's facing the mouth of the skeena river, so you don't get the crazy winds on the other side of the island facing the hecate straight, but the winters are sometimes described as severe because of the wind, so Don, I think you make a good point.

Milling 6 by 6 or 8 by 8 beams 18 ft long wouldn't be too much of an issue, and I can also let them sit for a month while everything else is cut and the foundation is set. What if I were to frame the exterior walls all with 6 by 6 beams, and then built stud walls within that? Does that make sense?

I've also heard that about pier and beam, but with pressure treated beams on concrete pads, i'm hoping i can make up for that by just having more piers.

poured concrete isn't really an option, can only get small boats in on high tide, so getting a truck would be pretty tough. So that's why I was thinking spot footings.

I think if structurally the cedar will be mine mostly green, then I'll go with that, large beams look great, and hopefully will be sturdier.

|

|

Don_P

Member

|

# Posted: 28 Apr 2015 06:55am

Reply

Bracing the posts will do more than putting many in. Another alternative, post frame buildings use 6x6 or 8x8 timbers that run from roof to footing and use the walls to brace the posts. They would need to be treated or a naturally decay resistant species, which WRC is... although I would go carefully there. Do you have rocks?

Yes, you can use heavy timber with stud infill. As the timbers dry they can leave gaps, so some thought needs to happen there. The loft support beam would probably need to be a good bit larger than 8x8 but that can evolve with the design.

|

|

Don_P

Member

|

# Posted: 28 Apr 2015 07:47am

Reply

The interior loft support beam would work as a 6x10 in #2 WRC for an 8' or shallower loft, an 8x8 has insufficient depth.

I've attached a sketch of a post framed barn, notice how the posts run from footing to top plate, the walls brace the posts from rotating and overturning. The footings need to be large enough not to overturn or uplift as the wind works on that tall lever arm of wall.

|

|

|

thbarnet

Member

|

# Posted: 28 Apr 2015 05:32pm

Reply

So I made a quick sketch of what I'm thinking. The first is a side profile and the second is a Front profile.

So side profile the foundation is three 8 by 8 posts, five feet long, and knee braves which extend 2ft down. I've heard that there is no frost line here, and I've also heard that its less than a foot. I figure if the post is 2 feet below ground, that should be alright. Also, if I add a 12" layer of gravel below the post and throw a few flat rocks or a 2" pad, it would make things fairly stable.

Should I have 2 rows of 3 spot footings, 6 spot footings in total, or do three rows of 3, 9 spot footings in total?

The sill beam would be an 8 by 8. The flooring would be 2 by 8's, fasted with metal joist hangers. The SIPS sound great, but getting them there would be really tough, also, maybe a little cost prohibitive. Going to try and get everything milled on site.

The two main sets of beams would be 16ft and 12ft. I would notch another 16ft 8by8 across this, with knee braces again.

The roof would be 20 ft long, that would include a 3ft overhang. Distance between beams would be 17.09ft.

Sould I be thinking of the beam in the middle to extend all the way to the roof, and then have 3 sets of horizontal beams to support the roof? Or would framing it as vertical 2 by 10s work?

Side profile

|

Front profile

|  |  |

|

|

rockies

Member

|

# Posted: 28 Apr 2015 07:02pm

Reply

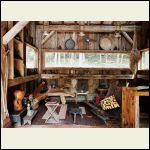

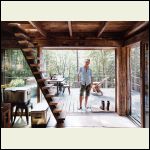

Well, this is the framing that the owner of the inspiration cabin did. It sounds like you can do a fair amount of post and beam up there with 6x6 or 8x8 timbers, so you might as well use them. Can you get "Techno Metal Posts" out there for the foundation? I know there are dealers throughout BC. They'll screw the post into the ground until they reach the desired depth, and you weld a "U" bracket on top to bolt in the foundation beams. Should be fine for any wind uplift, and they provide structural certificates for inspectors.

ScottNewkirkOffGR.jpg

|

ScottNewkirkOffGR.jpg

|

ScottNewkirkOffGR.jpg

|

ScottNewkirkOffGR.jpg

|

|

|

rockies

Member

|

# Posted: 28 Apr 2015 07:05pm

Reply

http://www.technometalpostbc.com/Contact.php

There's one in Terrace, BC

|

|

thbarnet

Member

|

# Posted: 28 Apr 2015 08:03pm

Reply

I don't know if that design would work. It's a 14 by 14 cabin in an area surrounded by trees, I don't think wind was a big factor in that design. My plan is 14 by 16, which will add an extra 2 feet of span to the roof.

It looks like his horizontal bracing is quite low for his main supports. So I think mine would need to be higher to account for the wind/extra footage. Is right on the ocean, so I think it needs to be very sturdy.

Thanks for the tip, I'll send the an email! I'm just thinking that treated wood piers might be more cost effective/will work good enough, I've heard that some last as long as 75 years!

Getting that equipment barged in and have a crew from terrace could easily run a few thousand dollars, and I don't have that kind of money. But I'll find out!

Thanks for the comments everyone!

|

|

thbarnet

Member

|

# Posted: 29 Apr 2015 03:41am

Reply

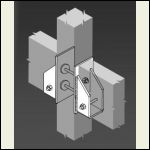

Anyone know of any metal brackets that can be used on the sill plate in the corner? That is, where the three posts meet in the corner? I found pics of how they do it the old school way, but I don't know if I have those skills.

|

|

Don_P

Member

|

# Posted: 29 Apr 2015 11:30pm

Reply

Worst first,

You are describing a high wind exposure site. In our tables they increase the design wind pressure 30% above the table values. That foundation isn't going to cut it if you get real wind. The treated wood we are using now came out around the turn of this century, just sayin.

Wander around on the timberframe guild's site, in their publications there should be a free download of Jack Sobon's "Historic American Timber Joinery". Excellent drawings of timberframe joints.

Simpson does make heavy timber steel hangers, connectors, etc.

Attached is a picture of one way of doing a corner also a pic of a steel post to frame connector.

oak_corner.jpg

|

beam_to_column.JPG

|  |  |

|

|

Rebel300r

Member

|

# Posted: 30 Apr 2015 12:30am

Reply

ctpostandbeam.com has some cool steel connectors that make it look like Timber Framing. I have not used them and can't get a photo to post.

Scott

|

|

thbarnet

Member

|

# Posted: 30 Apr 2015 12:38am

Reply

Right on! Exactly what I was looking for!

There's one neighbour that has an off the grid homesteading propert/their own mill, and they have a timber frame on a post and beam setup that's been there for 40 years or so, creosote piling and it's been fairly solid. So with some help and the right stuff, I think it can work.

The winter storms are what gets it, and the bay is mostly protected, the spot I'm thinking of has some good shelter, but wind is something I'm definitely thinking about, part of the reason why I want a solid timber frame with metal brackets. Think I might do a combination build.

|

|

thbarnet

Member

|

# Posted: 1 Mar 2016 09:19pm

Reply

Figured I'd post an update:

I've been back to the island a few times, the second picture is the site I've picked for the cabin. Spent a day falling a few trees and clearing a chunk of land. It's nestled up to a cedar tree that's about 10 feet wide at the butt, there's about 6 of those massive cedars close to the shore front. I've also cut about 900m of trail from the storefront to the cabin site and further along the ridge. This site is on a small plateau up the ridge and there's a gentle rise above it and a slightly steeper rise below it.

There's a seep I'm going to dig out for water not too far away, and the site is a good spot for wind protection.

There's lots of standing dead yellow cedar nearby. I'm going up this Sunday to dig holes for the piers, and if there's time, fall one of the yellow cedars, coat the ends in tar, and put tin caps on the end of them.

The only neighbor is an interesting couple that came up in the late 70s and have been living off grid. The catamaran sailboat was hand built by the guy some years back and that shop was built with block and tackle by the guy! Amazing craftsman, he cut the wood on his bandsaw and chainsaw mill, he salvaged massive logs by boat, inspiring character.

image.jpg

|

image.jpg

|

image.jpg

|

image.jpg

|

|

|

thbarnet

Member

|

# Posted: 1 Mar 2016 09:22pm

Reply

The first photo attachment is the cabin site before I cleared it out and that cedar tree is adjacent to the spot

|

|

|