|

| Author |

Message |

Josh8880

Member

|

# Posted: 16 Jan 2014 04:34pm

Reply

Hi out there..I'm planning a 10 by 14 shed style cabin for my property in NY. I picked the dimensions to maximize the 140 square foot I'm allowed to build permit/inspection free. My plan is to have an 8' side and a 10' side, (each would be the 14' sides). How do I calculate the angle I need to cut the top of my studs on the 10' sides? Also if anyone has any advice for how to frame the roof out, that'd be great! Thanks, josh

|

|

rockies

Member

|

# Posted: 16 Jan 2014 05:07pm - Edited by: rockies

Reply

I used an "angle calculator" on the web and entered a height of 2 feet (for your difference in height from an 8 foot wall to a 10 foot wall), and the width of the cabin at 10 feet, and it says an angle of 11.31 degrees. You can look at the construction process used by this websites moderator which is listed by headers on the left of the main page for how to build the roof. Bear in mind that you will have to use a wider piece of wood for your top plate and then trim the edges to the same angle (11.31 degrees) as the width of the studs so that the top plate doesn't stick out past the studs. The top plate will look like a trapazoid once you trim the sides.

|

|

MtnDon

Member

|

# Posted: 16 Jan 2014 05:13pm - Edited by: MtnDon

Reply

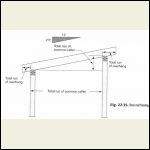

Do not cut the wall framing at an angle at the top. make them square just like any other wall. You cut two bird's mouths in the rafter, one for the upper end and one for the lower end. That saves messing around with making angled rip cuts on the top plates. Use H1 hurricane ties on each to make it easier to do and stronger.

Build the two walls and set them plumb. Use the rafter laid across the wall tops to mark the required angles and position. Do not cut too deep.

shed roof framing rafters

|  |  |  |

|

|

MtnDon

Member

|

# Posted: 16 Jan 2014 05:20pm

Reply

What is the snow load for the location? That will help determine what sizes the rafters need to be.

|

|

Gregjman

Member

|

# Posted: 16 Jan 2014 05:26pm

Reply

To help mark your rafters like mtndon is explaining you can pull a string from your high wall top plate to your low wall top plate (following the same plane as the bottom edge of the rafter in his picture)

From that string you can measure up to the top of the plate and transfer those measurements to your rafter. Cut one, fit it, then trace the notches in the rest of your rafters. Use the joist hardware he described.

|

|

rockies

Member

|

# Posted: 16 Jan 2014 05:37pm - Edited by: rockies

Reply

If you look at the picture provided by MtnDon, another option would be to keep the lower top plate on top of the studs flat like in a typical wall so that all the studs didn't have to be cut at an angle, but to bevel the top of the upper plate at 11.31 degrees all along it's length. You'd have to do that with a table saw, but this would require the least amount of calculating and cutting in the long run since all the studs would be cut at a regular 90 degree angle, and you could then just lay the rafters on top of the beveled upper top plate before fastening them down with hurricane ties. You also wouldn't need to cut any birds mouths in every rafter, just lay them on top of the walls and toenail nail them down.

|

|

bldginsp

Member

|

# Posted: 16 Jan 2014 05:52pm

Reply

I've never seen a beveled top plate. Unique idea, not common practice. It is very easy to cut all the birds mouths in the rafters all at once by ganging them together and cross cutting notches with a circ saw.

Since a beveled top plate is not level, in extreme circumstances downward force on the plate from the roof will force the wall outward. Best to keep all forces going straight down to keep all your forces geometry simple and plumb.

|

|

MtnDon

Member

|

# Posted: 16 Jan 2014 06:16pm

Reply

Yes, the idea is to build the walls and roof to have the weight act in a downward vertical manner. If the top plates are slanted there is a sideways moment that is being promoted and only restrained by the mechanical fasteners. Seriously doubt that would pass code. Yes I have seen it done and have always wondered why... birds mouths and gable raftered roofs are not that hard to make, but do scare off some folks.

|

|

|

rockies

Member

|

# Posted: 16 Jan 2014 06:22pm - Edited by: rockies

Reply

I don't think bevelling the upper top plate will affect the forces placed on the walls or cause them to bow outwards. The rafter being nailed to the opposing walls (plus hurricane straps) will tie it all together sufficiently and be more than strong enough. Just use a strong rafter, probably a 2x8, or a 2x10 depending on the snow loads. The practice of bevelling upper top plates comes from structural analysis' done by structural insulated panel (SIP) manufacturers, who use it precisely because birds mouths can't be cut into their panels in order to set them on top of the walls. If Josh8880 is out in the middle of nowhere or doesn't have a lot of building experience, the least amount of calculating, measuring and cutting possible is probably his best and easiest choice.

|

|

bldginsp

Member

|

# Posted: 16 Jan 2014 06:57pm

Reply

I can see a beveled top plate in an engineered situation such as you describe. And at 2/12 pitch the sideways forces won't be much. But if someone out in the middle of nowhere tried a beveled top plate on a steeper pitch and didn't know what they were doing, they could make some serious problems for themselves. Not a good idea to use an engineered design out of the context of its original engineering, unless you know exactly what you are doing. There are good reasons to stick with the program with conventional framing, it is the culmination of over a century of trial and error, and wisdom from others much smarter than me and the few of us.

|

|

rockies

Member

|

# Posted: 16 Jan 2014 07:31pm

Reply

I would agree that at a steeper angle there could be an increased risk of heavy loading on the roof causing problems with downward loading on the walls, plus as the angle increased there may be a danger from high winds pushing against the roof and causing trouble as well. However, at a 2:12 pitch or less I think that any "sideways" forces from a slightly beveled top plate would be minimal at best. Do check with your local building department first to see what they recommend. Another question I have is how are you going to finish the roof? At such a low angle you are limited as to the types of roofing allowed. You may have to do a membrane roof, either torch down or some other kind. Most shingles need a minimum 3:12 pitch, although some manufacturers make metal roofs for a 2:12 pitch or lower.

|

|

MtnDon

Member

|

# Posted: 16 Jan 2014 07:43pm

Reply

Quoting: bldginsp Not a good idea to use an engineered design out of the context of its original engineering, unless you know exactly what you are doing.

My thoughts as well. Many techniques do not transfer from one field to another.

|

|

bldginsp

Member

|

# Posted: 16 Jan 2014 08:48pm

Reply

I agree, Rockies, that at a low pitch it's far less an issue. I also think that in a remote build situation trying to bevel a 2x4 along its width would be harder than a birds mouth to accomplish, but maybe it's 50-50. And you are wise to caution about roofing on a low pitch. Comp shingles can be used at 2/12 if you double the paper, and metal roof is good at low pitch. But ice dam issues are more likely with any roofing on low pitch, so more and better underlayment is wise. Peel and stick over the whole roof is a good idea.

|

|

Josh8880

Member

|

# Posted: 16 Jan 2014 09:51pm

Reply

Thank you guys! What is your opinion of the pitch?(10' to 8' over 10' span) This is in Oxford, ny. There will be a good snow load.

|

|

MtnDon

Member

|

# Posted: 16 Jan 2014 10:32pm

Reply

45 to 50 PSF snow load if I have the location correct. 2x8 #2 SPF works, but I would go at lest to 2x10 and insulate it as good as you can. Problem is if you do heat it in winter there is a very good chance that will cause melting and then icing. It can be an endless circle of potential problems.

Any particular reason for a a low slope shed roof? Moderate to steep gable would stand a chance of shedding the snow load rather than providing a place for snow to accumulate. If the sun shines and then the snow forms a frozen crust it won't even blow off in a good wind.

|

|

bldginsp

Member

|

# Posted: 17 Jan 2014 08:43am

Reply

I agree- the only advantage to a low pitch is ease of construction and less building materials, but in all other respects it causes problems. And, with a gable, you can have a loft, which though small, may be large enough to sleep someone or give you storage.

You really want the snow to fall off the roof if possible. If the weight of the snow stays on for a long time, even if the rafters are rated for it, they gradually suffer from the weight and can sag. Steel doesn't do that, but wood is very complex structurally (not that I understand it all) but I do know you don't want a span to stay loaded with a lot of weight, such as snow.

But, that said, we are talking about a small building here, and if you do as MtDon says it will probably be fine, except for the ice dam problem. But, the ice dam problem can occur on steeper pitch roofs as well, particularly on the East Coast where there are constant freeze/thaw cycles. It's just less likely on a steeper pitch.

As I suggested before, peel and stick underlayment over the whole roof may protect the roof plywood from occasional water climbing under the roofing. It's expensive stuff, but on a small roof you don't need much.

|

|

rockies

Member

|

# Posted: 17 Jan 2014 03:13pm

Reply

This poor man. One little question and a flood of responses lol! Ice dams can be a problem if you do have snow melting occur from either heat escaping through the roof, or you have a very warm patch of weather in between two cold periods. Ice dams can be minimized by building a "cold roof". After you sheath the roof put 4 inch strips of peel and stick membrane about 16 inches apart across the roof (like vertical stripes running from the high side down to the low side). Mark the locations of the peel and stick pieces on the eave boards and then cover the entire roof with a layer of heavy building paper. Next nail 2x3 furring strips on top of the locations where you placed the peel and stick. The membrane will seal itself around the nails. Next add a second layer of 5/8 plywood on top of the furring strips and then another layer of building paper on this layer before putting on your finished roofing material.

This is more labor intensive than just a "single layer" roof, but the air flow under the top layer of sheathing really helps stop the heat coming from inside the cabin from melting any accumulated snow, you get air flow under the top sheating to help evaporate any moisture that might get in, and the air space also minimizes any heat gain into the cabin through the metal roof from the sun.

|

|

squidkid

Member

|

# Posted: 24 Jan 2014 04:01pm

Reply

FWIW,

We built a 14x14 with a shed roof with a pitch very similar to yours.

We added a (2) 2X12's glued and screwed together, as a main beam that ran perpendicular to the roof rafters. We simply doubled or tripled up some cripple studs in the outside walls and set the beam on them. With this beam placement, the roof rafters are only supporting a 7' span. This made us feel more comfortable with the potential snow load and the cost was minimal for the piece of mind given.

|

|

creeky

Member

|

# Posted: 24 Jan 2014 06:42pm - Edited by: creeky

Reply

Hey Josh, I built something similar for my solar shed a few years back. I did 10' to 8' over 8'. so a bit narrower. It came to 3/12 slope.

I used this calculator to find my rafter size

http://www.awc.org/calculators/span/reversecalc/reversecalc.asp

choose "roof rafter w/ snow load" and put in the span and the snow load and you'll be set. I ran the calculator with a 10' span and 50 lb snow load. It came up with 2x8 on 24" centers.

then google "how to cut shed roof rafters" for the birds mouth. The math is pretty simple and it works. I actually did a trigonometry refresher and then did the math old school on paper with a pencil. So hey. If I can do it...

I completely covered the 1/2" plywood roof sheathing with waterproofing underlayment and then put metal over that. I'm in a similar area to NY, maybe a bit less snow, and its worked out fine.

As Rockies mentions: I also did a breathing channel under the roof sheathing. I left a one inch gap in the siding at the top of each long wall. I protected the gap with wire bug mesh. Wasp and bat proof.

To insulate I put 6" roxul between the rafters. So I have a two inch gap between the roxul and the roof sheathing. The slope and the air channel allow for excellent air movement.

I closed with 1.5" foil covered styrene sheet which I nailed to the rafters for the ceiling. This gives a vapour barrier and additional insulation. I would use 1" foil polyiso insulation now. Less flammable. This would give you about an R30 ceiling/attic.

good luck.

|

|

Josh8880

Member

|

# Posted: 25 Jan 2014 03:02pm

Reply

Thanks creeky, very helpful. Where'd you build? I looked at your pics, nice spot!

|

|

toyota_mdt_tech

Member

|

# Posted: 25 Jan 2014 07:09pm

Reply

Quoting: MtnDon Any particular reason for a a low slope shed roof? Moderate to steep gable would stand a chance of shedding the snow load rather than providing a place for snow to accumulate. If the sun shines and then the snow forms a frozen crust it won't even blow off in a good wind.

Not to mention, if the snow is deep, then it turns to rain, then the snow becomes soaked with rain water, this is a scenario for may collapsed roofs, the weight becomes to great. What is water a gallon, about 8.33 lbs.

|

|

creeky

Member

|

# Posted: 26 Jan 2014 09:09am

Reply

Hey Josh, thx.

I'm posting more pictures today. And the solar shed build is in year two. Should go up this week. So drop by. There's a pic that shows the air channel a bit better too that'll I put up for you.

|

|

Sustainusfarm

Member

|

# Posted: 26 Jan 2014 12:40pm

Reply

Just use these: https://encrypted-tbn2.gstatic.com/images?q=tbn:ANd9GcTk_XQr0zkMZEg48bFb2REAuptkL3XD7 Aff1LhnsvaPrT2tQCkO4A

|

|

creeky

Member

|

# Posted: 26 Jan 2014 09:41pm

Reply

what he said.

|

|

|