| . 1 . 2 . >> |

| Author |

Message |

drb777

Member

|

# Posted: 13 Nov 2013 01:03pm

Reply

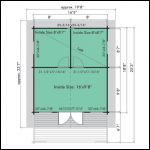

After several years of research, I was a bit apprehensive about cabin kits and just couldn't get excited about a panel kit or pre-built shell. But after finding that the largest supplier to the western euro market had a new US distributor, I went forward with their largest model. While awaiting shipment, I built a concrete pier & steel tubing foundation skid using surplus materials already on hand. When the kit was delivered in 4 large bundles last May, I was ready for assembly. As shown, it's a flat log, interlocking corner, artic spruce, double tongue & groove structure. So the walls are 45mm (1-3/4") thick, and has double pane windows & doors.

While I had a tractor w/ front loaded to help, I found it unnecessary, even though the entire construction was a solo build. For me it was a priority not to impose upon others any any way for this project.

I took my time to carefully consider each step, and choose to make several up-grades to make the cabin 4-season. I added R-Max insulation panels to the roof and under the sub-flooring. Also, I used composite decking on the front porch instead of the flimsy decking supplied with the kit.

I finished the structure/exterior in September and began interior and utility work. The 2 small rooms will be a bathroom/utility and a kitchen. The large room is for main living and the loft for sleeping.

I'll post interior photos if there is any interest, as I finish-out each room. I also have many photos taken during each part of assembly I can post as needed.

Lillevilla 220 Cabin Exterior Finished

|

floorplan

|  |  |

|

|

bldginsp

Member

|

# Posted: 13 Nov 2013 01:08pm

Reply

Very impressive looking. I'm curious-

-what R value do you now have for floor, walls and ceiling?

-what did the kit itself cost, and what was the delivery cost?

-cost of slab installation?

Looks like a viable, and fast, option

|

|

drb777

Member

|

# Posted: 13 Nov 2013 01:29pm

Reply

I'm not really sure what the resulting R values would be, but here are the components;

floor; 3/4" R-Max (5 R value)

3/4" t&g spruce sub-flooring

1/4" foam underlayment

7mm laminate

roofing; 3/4" t&g spruce

3/4" R-Max

7/16" OSB

30 lb felt + composite singles

walls are just the 45mm thick spruce logs

The kit cost about $17,000 delivered and unloaded.

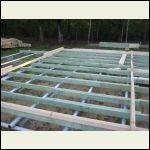

I built the concrete & steel skid foundation myself (no slab). The only cost was for concrete blocks and cement, about $200. (See photo)

concrete pier & steel tubing foundation

|  |  |  |

|

|

drb777

Member

|

# Posted: 13 Nov 2013 01:51pm

Reply

The foundation type was choosen for several reasons. First, the 25ft thick bedrock is very shallow at only 1ft down. Next, with solid walls, I needed underfloor space to run armored electric cable, insulated pex water lines, PVC drain lines and 3/4" steel natural gas lines. And lastly, I wasn't experienced enough to be able to predict placement of those utility lines before the cabin structure assembly. So the several inches of space below the sub-floor allowed me to locate all of the lines post assembly and avoid misplacement in a concrete slab. (see photo of bathroom sub-floor)

bathroom sub-floor utilities

|  |  |  |

|

|

rockies

Member

|

# Posted: 13 Nov 2013 04:59pm

Reply

Are you using public utilities for water, waste and electrical? What systems are you using and how are they connected? I take it you are building in a cold climate?

|

|

drb777

Member

|

# Posted: 13 Nov 2013 05:32pm

Reply

Water will be from a well directly behind the cabin. Waste will drain to a small septic system. Electric is from a extension of a 480v single phase underground system I own and operate. Natural gas is from a gathering system I own and operate (unlimited & free). Photo shows the electric (5 KVA transformer) and gas service next to the cabin. Note the lack of sales meters. The electric originates from the rural COOP, the cost is allocated to various accounts (by me) so amounts to almost nothing. I'll be installing a 5000 watt natural gas generator as a back-up, but wouldn't want the noise of a continuous run system. So, if things ever get really tough, I can be truly independent and comfortable.

The climate is moderate in NE Oklahoma, it can get down to single digits, but frost depth is almost never more than a few inches.

cabin utility service, elec & gas

|  |  |  |

|

|

lillevilla

Member

|

# Posted: 16 Nov 2013 11:22am

Reply

As the U.S. importer/distributor of Lillevilla cabins I can attest that the cabin featured by the user drb777 was unique. First of all, a solo built model 220 (or Lillevilla Getaway which is the U.S. model name) is an accomplishment itself. We recommend two people set-up even for smaller models. Secondly, the meticulous reports and feedback during the project were really impressive. Attention to detail was evident and the end result in the picture speaks for itself.

|

|

Jabberwocky

Member

|

# Posted: 31 Dec 2015 12:08pm

Reply

drb777: Hey you posted on a topic I had interest in a couple of days ago, as I too am looking at a Lillevilla kit as a permanent home. We would actually be considering their monster 837 sq. ft. kit. A little scared of them to be honest, just because I have no experience with log cabin kits. I'm greatly interested in your cabin as I too am in Oklahoma, and my primary concern is with insulation and staying comfortable year-round. Would you mind answering a few questions?

1) What was shipping cost roughly, or is it included in the kit price?

2) Have you spent any cold and windy days in the cabin, or extremely hot ones, and how does it do temperature wise?

3) Have you experienced problems with log separation? That seems to be a complaint I've read about by log cabin owners, but I don't know how valid it is. Do you have to re-seal every year?

4) What did you seal the logs with? (not stain, but meaning in-between them for weather-tightness)

5) Finally, since this would be a permanent home we would be hiring someone to pour a concrete perimeter foundation. Do you know how a kit such as this would be anchored to such a foundation? And what factors should be considered so as to avoid pitfalls of fitment to the foundation?

Thank in advance for any help!

|

|

|

drb777

Member

|

# Posted: 31 Dec 2015 09:02pm - Edited by: drb777

Reply

Jabberwocky, I can understand your apprehension towards investing in a such a pre-designed cabin kit. I had much the same concerns. Check and search Luoman Oy Industries of Finland to get more info. I had no significient issues dealing with their US distributor, they are also Finnish and well connected to the corporate powers for any support as needed.

Answers to your questions;

1) Shipping is not included in the listed prices. Mine was about $1000 for shipping from their stocking in NJ to my location in NE-Oklahoma. And that included unloading at my end. The maxie 837 sqft size would likely require 2 truckloads and therefore might double the shipping cost. And also might require a forklift for unloading. Contact the US distributor for details.

2) I've spent many weeks at the cabin, heating and cooling is not really an issue. I use a Vermont Casting gas stove for heat, and 12,000 BTU AC for cooling. And I supplement w/ a 5000 BTU unit in the loft during the summer, for short periods.

3) & 4) Log separation does not occur. The machined, double T&G logs fit together very tightly, no gaps whatsoever. No special sealing or re-sealing, and zero air infiltration. Vertical steel tension rods are used at each corner, but probably aren't really necessary.

5) The treated floor joists can be attached to your footing/foundation. (See pic below) Also, critical for easy assembly of such a tight-fitting structure is a flat, level (and square) base/foundation. The multiple interlocking corners and internal walls are machined to close tolerances, Out-of-square or an unlevel base will make assembly very tough.

6) As I said in earlier posts, insulation below the subfloor and in the roof sandwich is fairly easy to accomplish using R-Max foil-faced foam sheets, available at HD & Lowes. The 2" thickness is quite sufficient for the central US temps.

If you get to the point of seriously considering a Lilleville cabin and would like to spend a day w/ a tour of my cabin, let me know. I also live in the OKC area, but make the 75 mile one-way trip to the cabin nearly every week. Good luck.

|

|

OutdoorFanatic

Member

|

# Posted: 31 Dec 2015 09:06pm

Reply

Sweet! and different too! Live free or die.

|

|

drb777

Member

|

# Posted: 31 Dec 2015 10:24pm - Edited by: drb777

Reply

For interior photos go to URL

titled "Land Purchase"

Lillevilla US toll free (800) 985-8234

or email to info@allwoodindustries.com

BTW I have no relationship w/ them other than being a customer.

|

|

drb777

Member

|

# Posted: 31 Dec 2015 10:34pm

Reply

Also, see youtube videos such as;

https://www.youtube.com/watch?v=vFCvkmkDgNA

or search YouTube for "Lillevilla Cabin" for numerous ones of assembly, etc.

|

|

Jabberwocky

Member

|

# Posted: 3 Jan 2016 08:47am

Reply

^^^ Thanks very much for answering my questions, and the offer to see your cabin in person. After my wife got over the initial "sticker shock" she is starting to see the potential benefits of going this route. We have some more figuring to do. Even though it's virtually a 'house on a truck,' I realize that there will still be a lot of expense left to finish it out with plumbing, electrical, roofing, foundation, cabinetry, and appliances. But other than the foundation, plumbing, and electrical, at least with this option I will be capable of doing everything else myself. So I can definitely get behind the idea of only hiring 3 contractors!

I'm going to recreate the kit in SketchUp to determine if the layout will actually work for us. And I will contact the company to see if they can provide any more photos/information about the Eagle Point kit than what is available online. If I'm going to plunk $50K down on a house kit, I'm going to need a bit more information than what is currently offered, you know?  I get the impression that it is a brand new offering, because there are NO examples of one out in the wild yet. I get the impression that it is a brand new offering, because there are NO examples of one out in the wild yet.

Also, when you were shopping around, did you talk to Eagle Log Cabin co? They seem to offer the same thing, but a lot more designs to choose from. Their website sucks with broken links and no up-front pricing. So just wondering.

If we decide that a cabin kit is feasible for what we are trying to accomplish, we would very much like to come see you cabin in person sometime. Thanks again!

|

|

Don_P

Member

|

# Posted: 3 Jan 2016 10:23am

Reply

The thickness of the wall concerns me structurally as much as anything. I would want some form of engineering done to show that the wall is safe for the spans and loads. I think it would need an interior wall or post keeping it from buckling every 4-8' along the walls. I've built quite a bit with 6x and 8x milled logs and would put intersecting walls or wall stiffening posts in long walls.

Thinner boards dry better than heavy timbers. My experience with typical log home kits is that it is extremely hard to find a manufacturer of a dry log. Basic wood science, wood shrinks about twice as much tangential to the growth rings as it does radially, from heart to bark. When you dry a large timber this disparity in shrinkage typically creates convex faces, a pregnant rectangle, there's your gapping, and it opens up a large check, normally on the side where the heart is closest to the face of the timber. I would rather have the "log" machined after the timber is fully dried. For one I can hide the major check, and flat faces stay flatter. Hard to find truly dry in large timbers, easy in 2x dimension. So these should stay tighter. The stability of that thin wall is concerning as the building gets bigger. Pan Abode used to do a double wall, it looks like Eagle does too, $.

One solution I've seen is to laminate 2x material into a timber and then machine whatever profile they want on that glued timber. These are vertical laminations rather than horizontal as in a glulam beam. Cost is a problem, or educating a customer never worked for me. The Stoney cabin would be a DIY offshoot of that method.

Would applying regular 2x T&G over or inset into a post and beam frame accomplish the same goal while providing a stronger frame be visually acceptable and cost competitive?

|

|

drb777

Member

|

# Posted: 3 Jan 2016 11:26am

Reply

Jabberwocky, When I built, Eagle Log Cabin was not in existance. But from their website it appears part of their offerings are likely Louman Industries designs/products. Also, I am aware that Lillevilla (Louman) does now have some outlets that retail their various designs, such as www.bzbcabinsandoutdors.net

Don P, Actually, Lillevilla now offers wall thicknesses of 70mm (2-3/4") for longer spans and harsher climates, with stacked purlins for increased roof loads. And my particular model doesn't exceed spans of about 9' w/o an intersecting wall or corner.

http://bzbcabinsandoutdoors.net/shop/prefab-dyi-wooden-cabin-kits-for-sale/nordica-ca bin-kit-loft/

|

|

Jabberwocky

Member

|

# Posted: 3 Jan 2016 10:50pm

Reply

Yes Don_P, as drb777 said, the particular model I'm looking at uses 2-3/4" timbers rather than the thinner ones used for the smaller buildings. (Maybe you knew that and are still concerned about load bearings? - I dunno).

I've emailed AllWood and asked several questions... we'll see.

Eagle Log Cabins intrigues me, http://www.eaglelogcabins.com/residential-cabins.html they have a lot of designs to choose from, but their blasted web site is so incomplete I can't actually can't get a good look at anything beyond a tiny thumbnail image. It says a better website is coming soon, otherwise I would think that they aren't even in business anymore.

|

|

Don_P

Member

|

# Posted: 4 Jan 2016 07:35am - Edited by: Don_P

Reply

LOL, yes I did see the 70mm logs as well.

I would want someone other than their salesman saying it is adequate, a stamp should be part of the sale. I'll see if our engineer intern is done with my copy of the log standards but I don't think this will begin to hit the standards for a prescriptive design. Which would throw it into engineered design.

This is a newer company in the US it sounds like. This timber resource has been washing up on our shores looking for market share for about a decade. It looks like they are trying to move up from the garden shed category and enter the residential market. I sort of suspect they're gettin' ahead of their learnin'. I'd ask for a valid engineer's stamp on that design. I hope they can do it.

|

|

Jabberwocky

Member

|

# Posted: 4 Jan 2016 09:58am

Reply

I appreciate the heads up Don. I perhaps naively assumed that the very fact that they are selling such a kit means that some engineering has gone into it, only if to shield themselves from liability if nothing else.

|

|

Jabberwocky

Member

|

# Posted: 7 Jan 2016 01:25pm

Reply

drb777

Out of curiosity, how long did it take Allwood to respond to your inquiry? I sent them an email on Sunday and have yet to receive a response... do they want to sell these things or not?

|

|

drb777

Member

|

# Posted: 7 Jan 2016 02:44pm

Reply

I'd suggest you try the 800 number shown below, they told me that the main boss will be in tomorrow, and they will take note of your email inquiry.

(800) 985-8234

|

|

Jabberwocky

Member

|

# Posted: 7 Jan 2016 03:45pm

Reply

Thank you! I could've called myself, but it's difficult to make personal calls during work and I work 11 hours every weekday. That's why I went the email route. I appreciate your intervention

|

|

cscmtp

Member

|

# Posted: 9 Jan 2016 09:54am

Reply

drb777

drb777

Any chance I could email or call you with some questions? We are about to buy a cabin (or two) for our campground and I'd love to discuss a few things with you if you are willing! Not sure I know how to send a private message on here so I apologize for the public post!

|

|

drb777

Member

|

# Posted: 9 Jan 2016 11:15am

Reply

cscmtp

Sure, you can email me at drb777@email.com

|

|

Allwood

Member

|

# Posted: 9 Jan 2016 04:53pm

Reply

Dear Jabberwocky, this is Tapani @ Allwood. We show no inquiry related to Eagle Point cabins in our logs. I see an incorrect email to us address in one of the earlier posts and that may be the reason. Please send your inquiry to info@allwoodoutlet.com or info@allwoodindustrials.com.

|

|

Don_P

Member

|

# Posted: 9 Jan 2016 06:41pm - Edited by: Don_P

Reply

Quoting: Jabberwocky I appreciate the heads up Don. I perhaps naively assumed that the very fact that they are selling such a kit means that some engineering has gone into it, only if to shield themselves from liability if nothing else.

Tapani,

Have your habitable cabin kit designs been stamped by an engineer or can you provide this service as part of the sale?

|

|

Jabberwocky

Member

|

# Posted: 9 Jan 2016 11:09pm

Reply

Tapani: Yes, unfortunately it appears that I used an incorrect email address - thank you for clarifying. I have now sent the message to info@allwoodoutlet.com. Thank you.

|

|

Allwood

Member

|

# Posted: 10 Jan 2016 08:34am

Reply

Don, I am not sure what you mean by "kit designs stamped by an engineer". These kits are designed by in house architects and engineers to meet structural and other relevant requirements. Otherwise the manufacturers could face a huge general liability exposure. Our top three manufacturers combined sell annually over 100,000 cabin kits, in 30+ countries. Some of those require very thorough documentation; well beyond what is required here in North America.

|

|

Don_P

Member

|

# Posted: 10 Jan 2016 10:28am

Reply

These kits fall outside of our prescriptive (no engineer required) building codes (ICC400 in this case, standard for design and construction of log structures ), thus they are required to be designed by a registered design professional.

That is what I am asking for, and hopefully showing others how this properly works. I look for "Of course we provide that, the standard package is designed for X conditions (wind, snow, seismic, occupancy), do you require something outside of those design assumptions?"

In other words we are verifying first that the kit manufacturer has used a RDP, a registered design professional, for a non prescriptive design, and second that the RDP has used the right design assumptions for our locale. The same things we would do if site building without the kit manufacturer.

Tapani, I like what you're saying, however, you spoke in generalizations, go back and find those numbers. Jabberwocky, find those requirements for your location. You all coordinate that or do it here for all to learn. This is how a builder or inspector makes sure those liability issues are covered.

The liability here is potentially injury or death, it is proper to speak plainly with suppliers in these conversations and they understand this. This is how we cover our bases. When it is left to assumption and the fan lands I've seen everyone including the taco truck driver in the courtroom.

In the building official or builder's review of your engineering I look to see that the designer used the appropriate design loads for the build location, the local wind/snow and seismic loads plus our occupancy loads.

From hard won experience I've learned to "trust but verify", the requirement of a valid engineer's seal on the design is written into the contract with the kit supplier.

Another of our relevant requirements is the energy code, typically we do that through the DOE's ResChek program, a free download from their website.

drb777, I apologize for the thread drift, I sat on my hands until I saw this was turning into more than a one off.

|

|

Allwood

Member

|

# Posted: 10 Jan 2016 10:40am

Reply

David, just to clarify that the Eagle Log Cabins are not made by Luoman although some of the models look quite similar. Also, BZB Cabins and Outdoors is one of our dealers. I can heartily recommend them, especially if you need the assembly.

|

|

drb777

Member

|

# Posted: 10 Jan 2016 03:26pm

Reply

Don P You've made your point(s) and actually I do sort of resent you turning the topic about my cabin into your rant supporting regulatory governmental codes that mostly don't apply to small cabins. We all understand that General Contractors are hostile to the concept of cabin kits, for obvious reasons, but you seem to be addressing a problem that doesn't exist.

If you want to continue your Building Codes discussion, kindly start such a thread yourself. Be sure to include some verbage about all the members that have designed and built their non-coded, non-engineer stamped "habitable cabins", and how they are "liable to cause potentially injury or death". I doubt you'll find a lot of support in this forum.

In fact, I'm a degreed engineer w/ 39-1/2 years of hands-on experience. I spent almost 10 years working 60 hrs/week for a client cleaning-up behind a "certified & registered" engineer that was incompetant in every project he attempted. So I understand that "engineer stamped" proves and guarantees nothing in real life.

|

|

| . 1 . 2 . >> |