|

| Author |

Message |

hakalugi

Member

|

# Posted: 28 Nov 2012 08:44pm

Reply

Hi All,

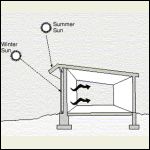

the more i think about some design needs***, the more I think i may end up with a shed roof, not even a single ridge line roof with gable ends.

*** (1) water catchment without perimeter gutters, just one gutter at the low side of the shed roof. (2) a taller wall at the south side for high clerestory windows to provide light "back into the space". (3) a single wall of windows on the south side with a properly sized overhang for passive solar in the winter months. (4) no ridge, no complicated roofing.

My county's design criteria are:

DESIGN CRITERIA

Ground Snow Load (pg): 35 lb/ft²

- Higher elevations (North Western parts of xxxx County) require 40 lb/ft².

- Section 1608 Uniform Statewide Building Code (USBC)/International Building Code (IBC) 2009. T1608.2 IBC lists Frederick County as 'CS' Case Study. Loading is based on historical performance and Figure 1608.3(1) of the BOCA Building Code as

published in the 1996 edition.

Basic Wind Speed (V) 3-Second Gust: 90 mph.

- Exposure Category: Exposure C, unless Exposure B definition applies. See USBC/IBC 1609.4.3.

Seismic Design Category: B, Section 1613.5.6 USBC/IBC 2009 edition.

Frost Line Depth: 24" below grade.

I'm thinking that a 20' x 40' rectangular footprint is where we'll end up, with the long axis east to west (so the long wall of windows is on the south wall) so, with a 20' span (forget wall thickness for now), and 6-7' of additional wall height on the south wall means my "hypotenuse" is about 20.9' long, say 21'. Add to this:

eave_width = Tan (latitude° - 23.433°) x wall_height

so for me, with an 9' wall + 6' of clerestory addition:

eave_width = 0.2817 * 15' = 4.22'

so that puts me at 25.25' that's some long solid timbers, if i can even find them, and likely can't afford them.

So.... I've seen posts here mentioning how people who build up "girders" (multiple 2x's sandwhich'd) should have the joints always line up above the non-perimeter posts. Yet here, I have no posts, i'm asking for a 21' clearspan and another 4+ feet of cantilever out the front.

Can site-built-up beams/girders/rafters be accomplished? (ie: meet code, be safe, etc). No chance i'm getting a crane up to my site, so i'd be building them and then build a winch fulcrum and use my truck's winch to pull them up there.

thoughts?

|

|

GomerPile

Member

|

# Posted: 28 Nov 2012 09:17pm

Reply

You can get 24ft microllam beams no problem at all. People do splice them using steel plates etc. it's something a structural engineer would need to figure out for you. The engineer could probably also guide you in a doing a built-up beam.

I'm using a 3.5 x 18 inch beam for a 17 ft ridge beam. It came in two sections and is screwed together. A helper and I just barely lifted each section into position. You will not be able to do a 21ft laminated beam with only one guy on each end. Two guys on each side should be possible....depends where it needs to go.

Here is a PDF that might help www.dickslumber.com/lumber_wood/documents/Microllam.pdf

|

|

MtnDon

Member

|

# Posted: 28 Nov 2012 09:50pm

Reply

IMO, a shed roof on a 20 ft wide in 90 PSF snow country is asking a lot, asking too much actually.

Without an engineer's official blessing you would never get a code official to pass built up rafters, unless all the splices occurred over a load bearing wall that was supported clear down to the soil/foundation. Then the rafters would be calculated in the supported segments.

The 90 PSF snow load is the killer. It would be impossible to clear span using dimensional lumber. Maybe using timbers, but you need an engineer for that calculation and blessing.

A gable roof built with rafters and good solid rafters ties could be build with dimensional lumber no problems. You could use #2 DF 2x12 for the 90 PSF and use 34" OC, though 16" OC gives more safety factor and a more solid roof deck.

How is the upper floor fitting into all this? Walls over 10 feet tall need lateral supports (like a floor or cross beams) or an engineer to bless the height.

|

|

hitanktank

Member

|

# Posted: 28 Nov 2012 09:52pm

Reply

I am doing same style as you are with the shed style roof but my area covered is much smaller, only 16 x 10. I am going to go with 12' 2x6 beams across on a 12/4 pitch leaving me an 8' back wall and an 11' 7" front wall. Like you I am going with just the one gutter on the low side for water catch from the tin roof. And putting the windows into the high space up front for more light.

Very similar design so I hope you do lots of updates that I can follow along.

Good luck

|

|

hakalugi

Member

|

# Posted: 28 Nov 2012 10:09pm

Reply

nice, thanks. I'd been googling 'parallam' since that's what i recalled seeing at a builder's show years ago, but seems the microllam does provide better hits. thanks for the link.

do you mind sharing what the ballpark cost of your single ridge beam was?

when you say 2 sections, do you have a post in the center under the joint?

thanks.

|

|

hakalugi

Member

|

# Posted: 28 Nov 2012 10:19pm

Reply

Don, i think you mis read:

"IMO, a shed roof on a 20 ft wide in 90 PSF snow country is asking a lot, asking too much actually... The 90 PSF snow load is the killer. It would be impossible to clear span using dimensional lumber. Maybe using timbers, but you need an engineer for that calculation and blessing."

It's 90mph **wind**. the max snow load is 40 #/sf. (this is Virginia, not NY  ) )

"How is the upper floor fitting into all this? Walls over 10 feet tall need lateral supports (like a floor or cross beams) or an engineer to bless the height."

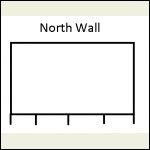

with 800+ sf of floor space, we'd be not building a loft of 2nd floor. I'd be bracing the "tall southern wall" with exterior pilasters for lack of a better term. Very small shear walls sticking out from the southern wall, like this in plan view:

_________north wall___________

| |

| |

| |

| |

| south wall |

_____ _____ _____ _____ _____

T T T T T T

But imagine the cross-bar of the capital T's being "on" the southern wall line. basically very short shear walls sticking out into the deck. These not only provide bracing to the 'tall wall face' but will house the side supports for my roll-down-metal doors.

|

|

hakalugi

Member

|

# Posted: 28 Nov 2012 10:20pm

Reply

^^^ crap, the site didn't like my empty spacebar spaces between the east and west walls.

|

|

hakalugi

Member

|

# Posted: 28 Nov 2012 10:24pm

Reply

Hitanktank, very cool.

I was originally thinking of starting with a smaller one - both as a proof of concept and to get 'something' up there, but being permanent, even if small, means plumbing and septic and all kinds of stuff i'm not ready for quite yet - so we're actually considering a Yurt on a deck platform as our "toe hold" structure. when the cabin is built, the deck platform would still be there for enjoying the view, but being a temporary structure (a tent basically) we're not required to do anything to/for it.

I'll look forward to any updates you provide as well.

Question: what's the spacing on your 2x6 beams? do you know your snow load? (just trying to get an idea of spacing vs. loading vs. span)

|

|

|

hakalugi

Member

|

# Posted: 28 Nov 2012 10:33pm

Reply

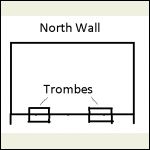

mtdon, like this, now attached.

i'm not sure it will be little shear walls for bracing the southern tall-wall and house the 'ends' of the roll down doors.

or if i'd do 2 boxes instead between 3 window sectoins, the boxes being Trombe walls as shown in the 2nd sketch.

planviewsm.png

|

planviewsm2.png

|

trombe.gif

|  |

|

|

hitanktank

Member

|

# Posted: 28 Nov 2012 11:11pm

Reply

Im just doing a standard 16" o.c. spacing,....I do not know the snow load at the moment but am actually trying to find out as I type this.

|

|

hitanktank

Member

|

# Posted: 28 Nov 2012 11:21pm

Reply

I cant find the translator so I'll just post this

Specified Snow Load

S = Is[Ss(CbCwCsCa)+Sr] [4.1.6.2]

Factors

Location: xxxxxxxxxxxxxxxxx

Ss = 1.5 kPa / Sr = 0.1 kPa

Importance Factor, ULS: Is = 1.0 / SLS: Is = 0.9

Roof slope = 18.4 degrees

Slope Factor

For slippery roof:

Slope between 15 and 60 degrees.

Cs=(60-18.43)/45 = 0.92

ULS:

S = 1.0[1.5(0.8*1.0*0.92*1.0)+0.1] = 1.21kPa

S = 1.21 kPa

S = 25.2 psf

SLS:

S = 0.9[1.5(0.8*1.0*0.92*1.0)+0.1] = 1.09kPa

S = 1.09 kPa

S = 22.7 psf

|

|

hakalugi

Member

|

# Posted: 28 Nov 2012 11:32pm

Reply

"S = 25.2 psf"

that seems low for a place that gets snow and sustained low temps to keep thaw in check. or maybe I'm just reading that wrong

canada and "translator" - are you in quebec?

i've skied mt. sutton, mt. glades and mt saint anne's hills too. nice area.

|

|

MtnDon

Member

|

# Posted: 28 Nov 2012 11:46pm

Reply

Quoting: hakalugi It's 90mph **wind**. the max snow load is 40 #/sf. (this is Virginia, not NY )

OOOPs!  I'll rethink and reiterate. I'll rethink and reiterate.

That comes out with 2x12, #2 DF on 16" centers being able to do 19'5". Right on the edge considering the calculation was made using only 10 PSF for the dead load. Using 2x12 the dead load should really be pushed to 15 PSF for safety. Then with 40 snow 15 dead the 2x12 on 16" only get rated to 18-6. Put the 12" OC and they're good to 21-4 (40+15 PSF).

|

|

MtnDon

Member

|

# Posted: 28 Nov 2012 11:53pm

Reply

A tall wall with no internal lateral bracing is really an area where an engineer is needed. It could be enough to build that wall with 2x8's and fully sheath it with 5/8 OSB. Lots of variables to consider and it is out of the realm of the prescriptive code book. The little buttresses could be the ticket but I would be guessing. The number and size of windows in that wall will also influence the stiffness of the wall.

|

|

hakalugi

Member

|

# Posted: 28 Nov 2012 11:56pm

Reply

thans mtndon. are those span figures for a shed like i'm saying (ie: clear span) or still gable/single-ridge as you were suggesting?

12" oc = 10.5" between, so the space between them would be deeper than wider  that's 41: 24' 2x12's that's 41: 24' 2x12's

when figuring the load, i assume one could double them up (two 2x12 bonded/screwed) and do 24" oc, as long as the roof deck material had the strength to handle the span? That would make the between-rafter insulation less insane to install as well as help the aesthetic in my opinion.

thanks.

|

|

MtnDon

Member

|

# Posted: 29 Nov 2012 01:09am

Reply

Quoting: hakalugi are those span figures for a shed like i'm saying (ie: clear span)

Clear span shed roof with the 40 PSF snow / 15 PSF dead load; DougFir #2, 2x12. Other species may vary some. What's your location normally have for sale? Varies widely around the country.

You could double the rafters in a sandwich and place those on 24" centers instead of separated on 12" centers. You could glue them but the issue there will be making tight intimate contact for an effective glue joint. Dimensional lumber is not quite as flat as furniture grade  An engineer will not count the glued surfaces for any extra strength because if the variables. If you want to glue don't bother with polyurethanes. They have low strength despite the ad claims and the product names. Myself I'd just use a few nails, every 32 inches and a couple inches in from their edges to help keep things together. An engineer will not count the glued surfaces for any extra strength because if the variables. If you want to glue don't bother with polyurethanes. They have low strength despite the ad claims and the product names. Myself I'd just use a few nails, every 32 inches and a couple inches in from their edges to help keep things together.

5/8 OSB would be a good choice of sheathing; 7/16 will usually be rated for 24". Depends on what you want to spend.

|

|

hakalugi

Member

|

# Posted: 29 Nov 2012 01:38am

Reply

thanks.

i'm going to spend some time at the local lumber yard(s) and see what they have. my primary residence is 90+ min away from the lower gate of this vacation spot we'll be putting the structure on, so "buying locally" with a shorter drive carrying lumber would make more sense, as does buying rural'ly vs. 'city pricing' where i live.

|

|

GomerPile

Member

|

# Posted: 29 Nov 2012 09:20am - Edited by: GomerPile

Reply

The finished beam came as 2pcs of 1.75 x 18 x 20 (ordered it a bit long). We placed one in the "saddle" then squeezed the second in next to it. There are some special screws that Lowes sells for screwing them together....i'm sure nails would have worked too. The cost was just under $300 for both.

The total span is just over 17 feet. I am supporting each end with a very beefy set of 2x6's. In this building its the main support structure for the house....no reason to skimp.

Quoting: hakalugi nice, thanks. I'd been googling 'parallam' since that's what i recalled seeing at a builder's show years ago, but seems the microllam does provide better hits. thanks for the link. do you mind sharing what the ballpark cost of your single ridge beam was? when you say 2 sections, do you have a post in the center under the joint? thanks.

|

|

hakalugi

Member

|

# Posted: 29 Nov 2012 03:18pm

Reply

gomer, thanks for the link.

|

|

|