|

| Author |

Message |

Rifraf

Member

|

# Posted: 30 Mar 2012 02:23pm - Edited by: Rifraf

Reply

My backup plan is to use 2 inch rigid foam with 1.5 inch air gap in my vaulted ceiling.. but the cost of rigid foam is pretty high for me.. so my other thought was this.

Do as I was going to and apply a 1.5 inch spacer on the sides of the roof supports, but instead of placing rigid foam on that, put up a radiant barrier film and maybe use some great stuff, or seal tape on the sides to get a good seal, then apply 2 inch batt insulation , then of coarse my finish ceiling material.

Do you think this would work well ? It would certainly be cheaper>

Thanks

|

|

Just

Member

|

# Posted: 30 Mar 2012 04:42pm

Reply

2 in foam =R 10

2 in BATT = R5

pay me now or pay me later

|

|

JoshG

Member

|

# Posted: 30 Mar 2012 04:59pm

Reply

From what I gather, with a 2inch insulation and 1.5inch air space, you are using 2x4's for rafters? Is the cabin already constructed? What is the span of the 2x4's? If you could upsize to 2x6's or better, you would have a stronger structure, allow for more insulation and still have your air space. However, if you already have it built and are settled on the 2x4's, my advice would be to use styrofoam vent chutes from eave to ridge, and then use standard R-13 Kraft faced batt insulation. You will lose a little R-value because of the venting, but I believe this is your best option given your situation.

|

|

MtnDon

Member

|

# Posted: 30 Mar 2012 08:05pm

Reply

I would NOT go with only the radiant barrier, especially in a roof where it will get dusty over time. Dust reduces the ability to reflect the radiant energy. That happens in walls too but it's a slower accumulation.

When you have limited space to use for the insulation XPS foam is about the best. Polyisocyanurate is a bit better (higher R-value per inch) but is more pricey than XPS. But some polyiso has a layer of aluminum foil as a reflective (radiant) barrier. That's what I'm using in my remodel / reinsulate of our home. I figure the radiant portion is costing me very little extra and will probably help in the hot sunny summer. Air space between the foil and the lap siding.

|

|

Rifraf

Member

|

# Posted: 30 Mar 2012 08:50pm

Reply

Thanks for the replies.

Yes the cabin was preconstructed using 2x4s for the ceiling

MtnDon. I wasnt going to put up only the radiant barrier, but put it above the batts, ill look into XPS foam too, thanks!

|

|

MtnDon

Member

|

# Posted: 30 Mar 2012 09:26pm

Reply

I missed that I guess... Radiant barrier above the batts with air space above can help when the sun is beating down. But the radiant barrier does very little, if anything, when it's a cool night and the inside heat is wanting to escape.

|

|

Rifraf

Member

|

# Posted: 30 Mar 2012 10:09pm - Edited by: Rifraf

Reply

True, but my ac should have an easy job transfering the hot air out once the sun goes down right ? (through the wall 14k btu, rated i think around 700-800 sq ft mine is 350 ish)

If money is a problem, would you say that my idea is would work out ok, or still recommend saving until I can pop down 400.00 for the spx foam boards needed to cover my 32 x 12 ceiling.

only ones i could find here here

HOME DEPOT LINK

Thats also another 150lbs load on the roof with foam boards.. wow i didnt realize that item would be 10lbs  , i dont think thats an issue I was just surprised by it, i thought it would be pretty light.. a few lbs maybe. , i dont think thats an issue I was just surprised by it, i thought it would be pretty light.. a few lbs maybe.

|

|

MtnDon

Member

|

# Posted: 31 Mar 2012 01:37am

Reply

JoshG's idea of running the styrofoam vents eve to ridge has merit. That would keep a vent path open. You'd have to see how much the vent chutes compress when squeezed by the batts. I've only used them with cellulose blown against them.

I understand it's a balancing act between money and insulation. I like the most insulation I can afford, just like you and most other folks. The hard part for me sitting on the sidelines so to speak, is that I am familiar with my financial situation but not that of you and others. Not sure I can help on that part. You will have to figure that one out.

Hope I've been some help

|

|

|

Rifraf

Member

|

# Posted: 31 Mar 2012 11:29am

Reply

Hey guys,

Thanks again, yes all the replies are so very helpful. Im sure I sound like a child on these boards, I certainly feel like one most of the time and everyone has been very patient and willing to give me as much info as they have.. I really do appreciate it.

-Jeff

|

|

JoshG

Member

|

# Posted: 31 Mar 2012 07:32pm

Reply

The chutes I use have reinforcing nipples (for lack of a better term) in them, so they should withstand compression issues.

|

|

Rifraf

Member

|

# Posted: 4 Apr 2012 11:01am - Edited by: Rifraf

Reply

Thanks Josh and MtnDon,

About 2am on Friday morning im heading to the cabin.. have all my materials ready. I was pondering this part again though.. would it be useful to help r-value to cut the insulation thinner where the baffle will compress it most ? my crude illustration below shows what i mean.. or so you think compressing the 3.5 insulation by over half in some spots is still better rvalue ?

My little sketch doesnt represent any real scale , the baffle is about 1.5 inches deep , and my rafter cavity is a 2x4 so 3.5 inches deep there

|

|

MtnDon

Member

|

# Posted: 4 Apr 2012 02:16pm

Reply

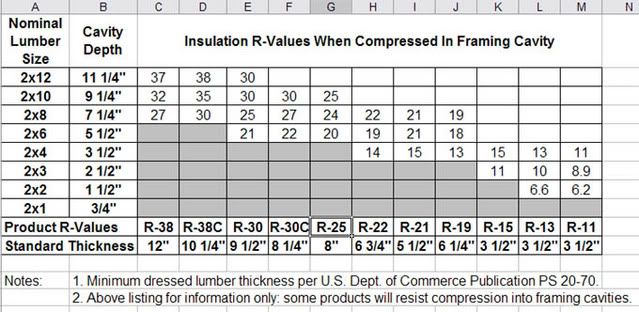

Hmmm. ??? If we take an R13 batt / 3.5" = an R-value of 3.7 per inch. I.m not sure that R is linear though. But for arguments sake lets say so. The chart indicates that compressing that one inch the R-value becomes 10, a loss of three. If an inch was to be cut out you might lose 3.7. So maybe it's better to compress? Easier, less work too.

|

|

Rifraf

Member

|

# Posted: 4 Apr 2012 03:37pm

Reply

Easier works for me, thanks

|

|

Rifraf

Member

|

# Posted: 10 Apr 2012 05:13pm - Edited by: Rifraf

Reply

my foam baffles arent going to work on my ceiling, they wavy pattern is a problem, fortunately I got these second hand for about 20 bucks. soo cost effective idea #2

line the edge of each cavity with 1.5 inch deep, x 1 inch wide foam liners, then use this product

home depot link

to stick up there bridging the foam liners and making a 1.5 inch air channel.. then install some r-11 3 inch faced bats slightly compressed to about r-9 (giving me a total of r-10 with the super thin foam board)

What do you think of this idea ? should only cost about 75 dollars more than bats alone.

|

|

yankeesouth

Member

|

# Posted: 10 Apr 2012 08:30pm

Reply

Rif

I used "used" 2" rigid foam I found on c-list in my walls. works fine. kept 1100sqf cabin 70 degrees when temp was in teens with uninsulated floor.

|

|

|