|

| Author |

Message |

jrbarnard

Member

|

# Posted: 13 Oct 2011 06:08am

Reply

Okay, here is a thought I had so please tell me if it would possibly work, sorry if I cannot describe it well enough.

Need: building a 16x28 cabin (altered design Toyota showed me.. heh).

Want: A loft for more sleeping room.

Concern: Trusses or rafters span

Option #1 - Pre-built trusses. Would probably go with scissors spaced at 24". Issue - I do not know if they will give me enough height to have a good loft. All I want is a sleeping area, not worried about standing up etc.

Option #2 - Make a 29' beam (maybe 30 ft, overlap each end by 1 ft..) out of 2x8's or 2x10's side by side to make one solid 2xwhatever beam that spans 30'

Then space the rafters 24" and use the next side smaller either 2x6's or 2x8's. Prob use 2x8's.

I will have a 4x6 post at each end of the beam as well as one 8ft in at the edge of the loft, for support.

If it works out well and does not take too much of the space, I might be inclined to make a loft at each end, just for storage etc. That would still give me 12ft in the middle of vaulted ceiling, right?

Either way, 1, 2, 3, or 4 4x6 posts...what would you think would be enough to support that roof?

Oh, and roof would have radiant barrier, felt, and then either a metal roof or shingles. I want metal, just gotta figure the costs as I do not want the really shiny galvanized ones as the Texas sun will blind me when outside.. heh

Thanks!

Russ

|

|

dvgchef

Member

|

# Posted: 13 Oct 2011 08:50am

Reply

If I understand your post, you are trying to decide on prebuilt trusses or hand built. I went for building my own because of the headroom issue. I installed them by myself, but if I do it again I would have 1 or 2 extra pairs of hands to make it easier. I included collar ties, but high enough so I could stand. With collar ties, one 4 by 6 post at each end should work, although I have never built anything as large as what you are doing. Good luck!

|

|

jrbarnard

Member

|

# Posted: 13 Oct 2011 09:22am - Edited by: jrbarnard

Reply

I will have about 6-8 guys out there helping me build this in a week, so having enough folks should not be an issue. I will look up collar ties to see what you are referring to, Thanks!:)

Okay, I see what you are referring to. Yea, I will add those too!

Russ

|

|

MtnDon

Member

|

# Posted: 13 Oct 2011 10:54am - Edited by: MtnDon

Reply

A picture is worth a thousand words... collar ties, rafter ties....

A roof needs both. Collar ties keep the peak together, keeps high winds from peeling it apart. Metal straps over the top connecting each rafter is good too. Rafter ties keep the wall tops from being pushed apart by the down and outwards force from each rafter. Rafter ties should be at each rafter pair. Note that many builders do this wrong. A loft floor, when dropped down the wall studs is not a rafter tie anymore. It is difficult to get headroom in a loft on a narrow building.

If you do a ridge beam with a support at each end the beam must be stout enough to hold 1/2 the total expected load of the roof including forces from high winds, etc. Then the support posts must be sized to be able to hold that and transmit it down to the foundation.

What is your foundation??

How tall are the side walls?

|

|

jrbarnard

Member

|

# Posted: 13 Oct 2011 11:00am

Reply

Side walls will be 8ft.

Foundation is solid cement blocks.

The base will be double 2x8 with beams every 8' that are also double 2x8's. The joists will all be under 8' long spaced 18" apart made of 2x6's.

The collar tie needs to be low enough to be effective, but I will make sure those are 2x6's and leaves just enough space to make a little room for a futon type bed.

Thanks for the input!

Russ

|

|

trollbridge

Member

|

# Posted: 13 Oct 2011 11:07am

Reply

Russ,

I will try to explain what we did but it may be helpful to look at pics of our cabin. We are 24' wide and 26'long. We made a main beam 26' long out of 2x12 LVL's sandwiched together. I think it was 2 12'and 2 14' staggered when put together-following me? Our rafters we made ourselves out of 2x12 x18's. We have a 12/12 roof pitch but we have snow loads that I don't think you would have to worry about. They are spaced 24oc. We have a 3/4 loft(L shaped) and it is supported by some interior walls that enclose the bedroom below and we used more LVL's to achieve the span we needed in other spots where it is more open below. Make any sense? Our side walls are 10' high. Our roof is shingled and I had seen on another post that you did not think you could collect water off a shingled roof. Not true-just need to filter, it's not for drinking correct? Hope this helps!

|

|

trollbridge

Member

|

# Posted: 13 Oct 2011 11:17am

Reply

MtnDon,

If there are 10f walls and a loft floor at 8' doesn't it more or less act as a rafter tie? I wouldn't think the walls would be able to bow out. Thanks.

|

|

jrbarnard

Member

|

# Posted: 13 Oct 2011 11:42am

Reply

Troll - I understand completely. You are right, we do not have snow, but ICE can be an issue.

I think I have a good handle on what needs to be done, but I may want to show pictures on here as I go along to get input.

R

|

|

|

MtnDon

Member

|

# Posted: 13 Oct 2011 02:17pm

Reply

Quoting: jrbarnard The collar tie needs to be low enough to be effective,

If it seems like I'm nit picking, so be it. A collar tie is in the upper third. The higher they are the better. Rafter ties have to be in the lower third to be effective. Also rafter size may have to be increased as the rafter tie is raised. There are tables in the IRC, with footnotes that address this.

more of an answer to come for troll bridge

|

|

MtnDon

Member

|

# Posted: 13 Oct 2011 03:04pm - Edited by: MtnDon

Reply

Quoting: trollbridge If there are 10f walls and a loft floor at 8' doesn't it more or less act as a rafter tie? I wouldn't think the walls would be able to bow out.

When a rafter tie in located in the lower third we have a triangle. If a load (wind) is applied to the roof face the triangle will not change shape as long as the materials are strong enough. We could use a large single pin at each of the three connections and this would still be true, although absolutely not advised. When the rafter tie is dropped below the top of the wall studs we now no longer have a triangle. We have a 5 sided shape whose strength against deformation now comes from the mechanical fasteners, solely. These shapes are much more easily deformed, so it is more than the simple matter of holding the wall tops in place that must be considered.

There will probably not be any catastrophic failure, and many of the cabins built with 10 foot tall walls and a dropped loft floor at 8 feet or so may not develop problems. However there is potential for problems. As the width increases and the snow and wind load become higher the risk increases. A steeply pitched roof helps as there is less outwards horizontal force with a 12/12 pitch than a 6/12 pitch.

A big potential problem comes from the usual technique of notching the studs for the 2X ledger. That turns a 2x6 into a 4 inch stud at that point. The floor joists will hold the walls together at that connection to the stud, if nailed with sufficient nails. Then the entire horizontal force from the rafter is acting on that stub of a stud. That upright stub will act the same as a cantilevered floor. The notch in the stud is a weak point. Any failure will almost certainly occur at the back of the notched area. If the grain slope is outward at that point that increases the likelihood of a split.

Stud grade material is not graded to have great strength with a bending moment applied to one end, like in such a wall and loft connection. It is graded for compressive strength, axially down its length. If the notch is made close to a knot, there is even greater concern. Stud grade material is permitted to have more grain slope. This is the angle of the grain across the width of the stud. It is expressed as a ratio. Stud grade is allowed to have as much as 1:4 slope. That is the grain can move as much as 1" across the width for every 4" of length.

If anyone wants to pursue building a wall/loft like this they would be advised to buy at the very minimum #2 grade. There is less allowable slope; 1:8. Select grade is allowed only 1:12 slope. This is one reason the #2 and higher grades can be used for floor joists, rafters and headers; they have greater resistance to bending.

Another thing that could help the survivability of a dropped loft floor would be to reverse the location of the notch. That is place the notch in the outer face of the wall. The joist would then extend to the full building width and rest on that ledger. The joist would also be nailed securely to the stud. That way the stud bending force would be trying to bend/compress over the ledger and the ledger would help resist that. This will not be found in any code book but an engineer I have talked with agrees it might be better than the usual way. Again though, knots in the wrong place could greatly weaken the stud.

I have run some calculations in the past using notched 2x6 wall studs. Even with higher grade lumber once the building width gets wider than 12 feet the forces add quickly, especially when local snow loads are accounted for. All it takes then is for mother nature to do something unusual, lots of wet snow or exceptionally high winds, maybe some seismic activity, and there could be a calamitous event.

Most failures, on the other hand, will occur slowly over time, sometimes many years. If you have ever seen a roof ridge line that sags in the center, that is outward horizontal rafter thrust at work on an insufficiently braced wall.

I have not met an engineer yet who looks favorably on such loft floors with raised upper kneewalls. I have talked with a couple, corresponded via email with another and read a few papers on the subject. None would sign off on the typical wall/loft thing we are discussing here.

Of course as long as there are no code officials to be dealt with anyone can build whatever they want. And in most cases it will not come crashing down. As I've said many times " Just because something has been done and has not failed, that doesn't make it good design." Likewise, "Just because something has been seen or done someplace on the internet, doesn't mean it's good/wise/smart/true...."

Just an extra informational note: Let's say we rip a 2x6 out of a number 2 grade 2x10. It does not necessarily follow that the 2x6 is still grade #2 material. A lot of the grading criteria comes from allowable knot size per width. Ripping a #2 can result in having two pieces of utility grade material.

|

|

jrbarnard

Member

|

# Posted: 13 Oct 2011 03:16pm - Edited by: jrbarnard

Reply

With all due respect, and not to be argumentative, but every source on the internet that I have seen states that a common issue of rafter downward thrust, and subsequent high wall cracks or splits, occur due to a collar being too high to be effective.

Take an example of trying to lift a large boulder with a 12ft 2x6. You place a smaller rock close to the boulder and leverage the larger one with it. The applied pressure, while being in the opposite direction, allows the longer end of the 2x6 to exponentially gain a better thrust on the other end.

If you move the smaller rock further away from the larger one, it takes a heck of a lot more pressure to get leverage.

The same principle applies to downward thrust in relation to the collar. The lower the collar, the greater amount of thrust required to affect the rafter further away from the crest.

Now, if your goal is to hold the top of the roof together, then yes, higher is better, but my goal is to prevent outward thrust at the base, which should in turn keep the top together as well.

And, btw, I think that in the situation of most cabin builders, the idea of the collar is to take the place of a rafter tie, to allow for more loft room. So, that being the case.. I think we may both be right, just using the same tools for different goals.

Russ

|

|

MtnDon

Member

|

# Posted: 13 Oct 2011 04:00pm - Edited by: MtnDon

Reply

Quoting: jrbarnard With all due respect, and not to be argumentative, but every source on the internet that I have seen states that a common issue of rafter downward thrust, and subsequent high wall cracks or splits, occur due to a collar being too high to be effective.

That should read the problem is because of the missing rafter tie.

You can believe and do what you wish. I choose to believe structural engineers and they say a proper rafter roof has both collar ties and rafter ties as illustrated above. There are also other solutions, attic trusses and the use of ridge beams (not a ridge board) and suitably sized support columns at each end alonmg with the required foundation support.

From what I have seen there is much confusion over the terms collar tie and rafter tie; hence the image.

You are right that many cabin builders eliminate the rafter ties because they want a habitable loft. I understand that. I also understand that placing the "rafter ties" lower in the wall as loft floor joists, and lowering the collar ties and then hoping the structure will withstand whatever mother nature throws at it does not take the place of engineering.

We're all free to do as we please.

|

|

trollbridge

Member

|

# Posted: 13 Oct 2011 05:56pm - Edited by: trollbridge

Reply

Thank you MtnDon for all your research,knowledge and time put into responding to my question. I really appreciate it. Of course we would like our cabin to "stand the test of time" that is why I asked. I should have mentioned that our loft is tied into the wall differently. It is not notched and sitting on the 2x6 wall. It is joined to the wall by joist hangers. The joist hangers are actually attached to a 2x10 that is attached to the walls. I'm not sure if that makes things better or worse. We have talked about putting in rafter ties and are not opposed. It,of course, would be easier now than later. Thank you for letting me "pick your brain". I should also mention we have a ridge beam that is supported by 4 2x6's.

|

|

toyota_mdt_tech

Member

|

# Posted: 13 Oct 2011 06:44pm

Reply

Ok, I'd use the rafter system. If you splice, I think you need a few feet ov overlap on the ridge beam or you could get an engineered unit. Then rafters from that down to the top of the walls. What I did was cceiling rafters on top of the wall, then my roof rafters set on each side of the ceiling rafters. I anchored the roof rafters down in addition to tying them to the ceiling rafter. This will act as a rafter tie. I sheated my atic floor to just make building the roof easier (walk on flooring instead of 2 inch wide rafters) I did add a collar tie on the top. My attic is all open, except the collar ties every 4 feet (every other radfter at 24" OC)

|

|

MtnDon

Member

|

# Posted: 13 Oct 2011 06:58pm - Edited by: MtnDon

Reply

Quoting: toyota_mdt_tech Ok, I'd use the rafter system. If you splice, I think you need a few feet ov overlap on the ridge beam or you could get an engineered unit.

If you build your own ridge beam the lengths need to be continuous or supported by a post or bearing wall directly under any splices.

A factory made, engineered beam is different.

As long as those ceiling rafters (joists) are sufficiently nailed to the wall top plate, and the rafters themselves have sufficient nailing that sounds like a good strong roof/ceiling/wall.

|

|

MtnDon

Member

|

# Posted: 13 Oct 2011 07:58pm

Reply

Quoting: trollbridge I should also mention we have a ridge beam that is supported by 4 2x6's.

With a ridge beam the game changes. As long as the beam is sized properly and supported all the way down to the foundation that is perfect. The rafters then exert no horizontal outward force on the wall tops and kneewalls are fine. Totally different from having a ridge board, which is actually just a spacing device, carries no load. That puts half the roof load on each wall, some vertical and some horizontal.

In your case hanging the loft floor joists on metal hangers is fine, that's the type of thing they are made for. On the other hand joist hangers used where the rafters are exerting a horizontal force out on the wall, hangers are a very bad idea. In that application the hangers offer no restraint to outward movement.

However, that raises the question of what is holding the 2x10 to the studs? All the weight of the loft materials and content (people) is beinmg held by mechanical fasteners by the look of it. If we use conservative values and assume the 2x10 and studs are typical spruce-pine-fir the calc. comes up with 16D common nails (0.135" dia X 3.5" long) each capable of supporting 88 lbs. (That's for true 16D nails not necessarily smaller dia and maybe shorter as some(many) air nails are.)

Ideally adding some studs under the 2x10 that can carry the load down to something solid in the floor, as in a floor joist. You could add a stud flat against the wall stud under the 2x10 as long as there is more than just sub floor material to support it.

Lags screws can increase the mechanical strength. A 3/8 x 4" lagscrew with washer would have a shear strength of about 180 lbs. Note: lag screws must have the side member (the 2x10 in this case) drilled through with a shank size hole and the main member (stud) must have the proper size pilot hole (15/64) for that strength value to be valid.

For future reference, when working with wood it is better to stack one piece on another instead of using mechanical fasteners to carry the vertical load. Fasteners are best used to hold things together, while the load is carried by stacking. Properly installed hangers are okay though. One of the reasons for this is that if there is a flaw in the wood, say a knot or a split, that obviates any strength of a nearby fastener. Sometimes splits can develop later if the wood contunies to dry a lot after the initial installation.

|

|

trollbridge

Member

|

# Posted: 13 Oct 2011 08:39pm

Reply

Thank you again. Well, we fastened the 2x10 to the wall with 5 16D nails each. Our building inspector's only concern was that we use the joist hanger nails in the joist hangers. Approved it all when we were done so hopefully we will be okay. Yes, in the future we will keep in mind to stack the wood for vertical strength. Once again, thank you for your help answering my questions and explaining it so clearly.

|

|

MtnDon

Member

|

# Posted: 13 Oct 2011 08:43pm

Reply

You are welcome. There are many ways to skin a cat, as they say, but there are some methods that do a better job. As I also said somewhere back there, most of us will never run into a problem. I do believe it is best to use the best methods to help assure that we continue to be lucky souls.

|

|

jrbarnard

Member

|

# Posted: 13 Oct 2011 08:48pm

Reply

Toyota: Pictures or it is all hearsay! ;)

Russ

|

|

raisadan

Member

|

# Posted: 14 Oct 2011 11:08am

Reply

There are 3 options for your roof: metal, metal or metal. It's more expensive up front but in the long haul it will be cheaper.

Best,

Dan

Kazan,Russia

|

|

toyota_mdt_tech

Member

|

# Posted: 14 Oct 2011 01:23pm

Reply

Quoting: jrbarnard Toyota: Pictures or it is all hearsay! ;)Russ

I have lots of pictures of the place, but never taken any of the attic. I wont be back till spring now. But I will take some pictures. I did add seveal ridge beam supports, even though the plan didnt call for it, the ridge is right over a load bearing wall, I also added an extra concrete pad in the crawlspace to transfer all that load if a tree did fall on it. I only did it incase a tree or large heavy branch blew on it in a windstorm etc. I dint want my roof to cave in or not as easily anyway. (I'm an HD type of person on everything) My rafters are all 16" OC, I went was overbaord on my design and they are nailed at the tails to the ceiling joist (nailed in the side) and they are strapped to the top wall plate. (a mental picture is as close as I can do now)

|

|

toyota_mdt_tech

Member

|

# Posted: 14 Oct 2011 01:27pm

Reply

Quoting: jrbarnard Toyota: Pictures or it is all hearsay! ;)Russ

Russ, I take it back, I do have pictures of it frames before sheating. I'll post up the one that shows the most. At work now, no access to my files. Stay tuned! :D

|

|

jrbarnard

Member

|

# Posted: 14 Oct 2011 02:29pm

Reply

roger! will do!

R

|

|

toyota_mdt_tech

Member

|

# Posted: 14 Oct 2011 10:51pm

Reply

Ok, you can see my walls, ceiling joist and rafters are all 2X6. Floor was 2X8. The ceiling joist lay right over top the wall stud, on the double top plate, the rafter lays just beside it, the rafter is nailed tot he top plate, also nailed in sideways to the ceiling joist (so I guess this would make for my rafter tie and the rafter is also anchored down with metal strapping from Stimpson ties using the special nails (Tikko) with the "10" on the nail head.

I sheeted the attic area. Reason was for the sheer easy of laying out the roof and rafters. Much easier to walk on a flat floor than a 1.5" steps 15 1/2" inches apart. Also, I knew I would have much nicer storage that way anyway. I insulated the ceiling from underneath, then sheeted the ceiling after insulation.

Framed walls and ceiling joist

|

Rafters at 16" OC

|

Day one of construction

|

9 days later

|

|

|

toyota_mdt_tech

Member

|

# Posted: 14 Oct 2011 10:52pm

Reply

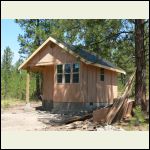

And where it sets today.

|

|

|