| << . 1 . 2 . |

| Author |

Message |

DRP

Member

|

# Posted: 18 Feb 2025 04:50pm - Edited by: DRP

Reply

It takes about 1000 btus per pound to vaporize water.

There are around 8500 btu's per pound of dry (0%) wood.

Hmm try it with a pound of say 50%mc wood

1/1.5=.666 lbs of dry wood x 8500 btus=5666.6 btus available.

1-.66=.34 lbs of water x 1000= 340 btu's to vaporize the water.

5666 btus available - 340 tied up flashing off water =5326 btus heat.

The big thing we feel is it is hard to get the stove above steam heat initially until the water is gone. Once you have a good hot coal bed it doesn't hurt as much to throw on some green wood as trying to get some heat going with green wood.

I forgot to mention why the thermometer was in my pics. I knew the wood was cool and there would be a temp correction to the meter reading. For ~50F the correction was ~2% and when I let the wood warm up and checked it again it read 3% above the original reading. Not huge but another factor. At zero F the correction would have been +6 degrees, so it does get pretty far off as extremes. Likewise at 120 a 12% meter reading would actually be -3%, 9% mc wood. Just stuff to keep in mind as you meter away from room temp.

|

|

paulz

Member

|

# Posted: 19 Feb 2025 07:52am - Edited by: paulz

Reply

Quoting: DRP The big thing we feel is it is hard to get the stove above steam heat initially until the water is gone. Once you have a good hot coal bed it doesn't hurt as much to throw on some green wood as trying to get some heat going with green wood

Yes! Lighting a days cold stove takes dry kindling. I have a stack of old fence boards I split into half inch pieces, along with the used paper plates we eat off of. Then add aged branches until a nice red bed of coals. After that just about anything thrown on will burn. Here’s one of the wettish pieces I just threw on, it will go just fine in a bit.

In fact it can have an advantage. If a dry night log is put on before bed, it will roast the place for a few hours, then cold in the morning. A wetter log will burn more slowly and keep going until morning with a nice even temp.

IMG_4398.jpeg

|

IMG_4399.jpeg

|  |  |

|

|

gcrank1

Member

|

# Posted: 19 Feb 2025 10:23am

Reply

The joys of learning how to keep your fire stoked

|

|

paulz

Member

|

# Posted: 19 Feb 2025 11:12am

Reply

See what you’re missing not having a wood stove at the new place?

At least I don’t have to think about the LP heater dying out. I did run the Williams the other day to make sure it still ran, in case I run out of 10 acres of wood.

|

|

DRP

Member

|

# Posted: 19 Feb 2025 11:17am - Edited by: DRP

Reply

Since we're talking about it...and its snowing again.. more meter trivia.

The main thing I use the meter for is to check the condition of wood in relation to the environment it will go into. Shrinkage and the warps (bow, twist, cup and crook) are all a result of moisture content change. Whenever possible and especially with finish materials we try to match the moisture content with what it will be in service. When the wood is no longer drying to the environment nor adsorbing moisture from it, it is considered to be at "equilibrium moisture content" with its surroundings. Obviously the surroundings are always changing in temp and humidity, so wood is always trying to reach emc. But it does work. Look at the table posted and the thermometer/hygrometer and meter readings... mighty close. The table is from chapter 4 of the "Wood Handbook" from the USFPL;

https://www.fpl.fs.usda.gov/documnts/fplgtr/fplgtr190/chapter_04.pdf

|

|

paulz

Member

|

# Posted: 19 Feb 2025 12:33pm

Reply

Supposed to be rain over here but just went out to take this photo and a brief shower going on.

I built my deck out of logs I milled here, some I cut the trees down to build the road, others were already lying around. Here is one edge today, obviously was a straight cut back when (didn’t drink That much!). Why that one shrank so much I don’t know, freshly cut?

IMG_4402.jpeg

|

528.jpeg

|

IMG_2830.jpeg

|  |

|

|

DRP

Member

|

# Posted: 19 Feb 2025 02:38pm - Edited by: DRP

Reply

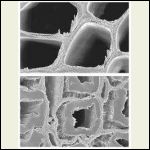

It is from green wood drying, but also from a certain green wood drying. Take a look at the pic below.

Normal, mature, easy living cells, have the microfibrils that make up the S2 layer(the thick part of the cell wall) running vertical, with the length of the cell.

"Reaction wood", whether it is juvenile wood from the first ~25 yrs of tree growth, compression or tension wood in response to a lean, or root or branch wood, has microfibrils making up the cell wall on a bias to the axis of the cell. If you've ever messed with cloth, bias weave orientation is more flexible.

Shrinkage is moisture leaving those microfibrils and them moving closer together. If they are normal the wood shrinks in thickness and width but not length. If the "MFA" microfibril angle, is at an angle to the length of the stick and those fibers get closer together... the board gets shorter as it dries. I've had it break screws when deck boards shrink in length.

That board contained a lot of reaction wood, I'll venture a cleaned up end pic will show it is near the juvenile core. It seems to have shortened uniformly.

Many warps in drying are a result of unbalanced reaction wood in the stick.

If there is reaction wood along one edge and not the opposite edge, then the board will crook (hockey stick) as it dries. If it is on one face and not the other the board will bow (boat side).

|

|

DRP

Member

|

# Posted: 19 Feb 2025 03:29pm - Edited by: DRP

Reply

Juvenile wood is one type of reaction wood.

In order to right themselves softwoods put on compression wood on the underside of a lean and try to buttress under the load, that unique cell structure in the sketch above is infilled with lignin, the cement of wood and is unusually stiff but because of the bias MFA it breaks weak and unpredictably. Its that dull peanut butter looking grain on the board in the middle pic, hey that was a southern pine log home job, we're ot. The biology takeaway, softwoods prop up leans.

Hardwoods throw a strap over the top of the lean and pull... hardwoods make tension wood. Somewhere they took 2 different paths to solve the same problem. There's a pic below of normal wood and tension wood with the central G, gelatinous, layer hanging out. That is the kevlar winch cable. If you are a woodworker and have had a hardwood board that could not be sanded smooth, it was always kind of fuzzy. That is those rubbery G fibers. I've been told thst Native Americans would gather bow stock from ridgetops where the windblown trees are. The takeaway, hardwoods throw a cable over and pull leans.

I also dug up some pics of compression wood. That deck board sheared 2 rows of screws and will lay back down flat after a long wet spell. One of these days I'll make her happy but I think it is cool to watch it shrink and curl, wet and lay down

tensionwoodop.jpg

|

compwood2.jpg

|

reactionwood.jpg

|  |

|

|

|

gcrank1

Member

|

# Posted: 19 Feb 2025 05:01pm

Reply

Nice ski ya got going there

|

|

DRP

Member

|

# Posted: 2 Mar 2025 06:19pm

Reply

I took another pic today of one of our fine deck boards. The pic is showing "cross grain checking" near the center of the board. Notice it is in the juvenile heart zone. This is showing what I was talking about above with that graphic showing juvenile vs mature cells. As the wood dries and shrinks the mature cells shrink in width and depth but not length. The juvenile cells where the microfibrils are laying at an angle to the axis also shrink in length as they dry. The mature cells on either side of the core restrained the juvenile wood as it tried to shrink in length. When the tension in the juvenile wood exceeded its strength, it checked across the grain. "RED" is a grade stamp you will often see on radius edge decking and it is a special set of rules/lower grade that allows more defects. We know it will not be spanning more than 24" so it isn't structurally necessary to have a higher #2 or #1 grade... but you see the downside. "Stud" is another one of those special lower grades. A stud is a #3 defect-wise with #1 edge restrictions so that sheet goods have good edges to break on. Fine in compression but not a good beam. You should never see a stud stamp on a horizontal, bending, member.

|

|

MtnDon

Member

|

# Posted: 2 Mar 2025 08:35pm

Reply

|

|

paulz

Member

|

# Posted: 3 Mar 2025 09:20am

Reply

Interesting DRP. I’m sure I’ve seen that checking around here somewhere, maybe on boards I milled vs. store bought. So that deck was already there when you got the place?

|

|

paulz

Member

|

# Posted: 21 Mar 2025 06:14pm

Reply

Just picked up some branches laying around and cut into firewood in the jig just behind the cart. Some had been on the ground awhile, some not I’m guessing because the chainsaw would get stuck halfway through on some, even though well supported. My understanding is this a wet wood phenomena. Why is that?

|

|

FishHog

Member

|

# Posted: 21 Mar 2025 07:55pm

Reply

if i understand your question right, simply because wet wood provides more resistance. Like pouring wet sand compared to dry sand. Makes the saw work harder when its wet.

|

|

MtnDon

Member

|

# Posted: 21 Mar 2025 08:34pm - Edited by: MtnDon

Reply

Hmm. In general I find green, wet wood chainsaw cuts easy, with a sharp chain. The moisture seems to act as a lubricant. Sawdust, especially with (sticky sap) pine, may build up more readily with wet wood and need more frequent cleaning. Maybe it is also species dependent??? Or depends on holding the saw straight so it does not cause binding???

|

|

paulz

Member

|

# Posted: 22 Mar 2025 08:55am - Edited by: paulz

Reply

Looks like two schools of thought on the internet. Mine seems like the swelling the wood pinching the bar thing. It goes through very dry wood, like the old fence boards I also cut up for kindling, no problem.

Why Chainsaws Stick in Wet Wood:

Swelling and Binding:

Wet wood can swell, causing the cut to close in on the chainsaw bar, leading to binding and sticking.

Sawdust Buildup:

Wet sawdust can stick to the chain, reducing its cutting efficiency and potentially requiring more effort to cut.

Increased Friction:

Wet wood can increase friction between the chain and the wood, potentially causing the chain to dull faster.

Sap and Resin Buildup:

Fresh, wet wood from some trees, like pine, can release sap that may stick to the chain, requiring more maintenance and cleaning.

Kickback Risk:

Cutting wet wood, especially with a mini chainsaw, could sometimes cause kickback if the blade binds.

|

|

gcrank1

Member

|

# Posted: 22 Mar 2025 09:14am

Reply

I cant believe water creating more friction, ever take a slide on a wet deck board? The liquid provides a boundary layer between the surfaces.

|

|

MtnDon

Member

|

# Posted: 22 Mar 2025 02:30pm - Edited by: MtnDon

Reply

We're at our cabin, but I don't have any wet wood to experiment with. But---

Disclaimer. I am a bit OCD on using sharp cutting tools and that includes chainsaw chains. I touch up every time I need to gas up. Sharp cuts cleanly when dull does not.

I could be wrong but this is my opinion formed after many years of felling trees, bucking fire wood and clearing up deadfall. A sharp chain cuts wet or dry better.

If the wood is wet, hasn't the wood already swelled up as compared to dry. A sharp chain should then cut the wood fibers cleanly, throwing nice sized chips. I don't think the wet wood is going to suddenly swell some more and pinch the chain or bar.

When cutting wet or dry I see similar sized wood chips, the cain pulls into the wood about the same I think. But that is not a side by side test. If I don't see the good chips, don't feel the chain pull or have to press the saw into the cut the chain is not sharp.

Oh, I remember that last week at home I trimmed some pine branches. Both dead and green..I used one of those curved blade extendable pole pruners. Nice sharp fairly new shiny blade. I don't recall a difference in pull required though I must admit I was not watching for differences.

Cutting logs I have had bar pinches; usually caused by the work shifting be ause the log was not properly supported, I believe.

Green wet logs or trees are also more flexible than dry. So the wood could flex a little that could cause the cut to close and pinch. Ah ha! But the cut could also open up, depending of other factors such as support or wind caused movement. So, I guess we could say wet wood could cause pinching but only if other conditions become factors.

Those are my thoughts. Now to go and split some of the pieces I cut last fall.

|

|

paulz

Member

|

# Posted: 22 Mar 2025 04:40pm

Reply

I bucked a couple of redwood spurs right off the main tree this morning.. No problem sectioning those. And I remembered I cut down a 6” laurel last week and bucked it no problem. These branches that gave me trouble had been sitting on the wet dirt for who knows how long, maybe that has something to do with it. Anyway all good, I’ll take some moisture readings next time..

|

|

DRP

Member

|

# Posted: 23 Mar 2025 09:19am

Reply

Going back to, if the wood is above fiber saturation point, it is already swollen, it isn't swelling more. The shavings, dust, whatever out of a kerf is several times greater in volume than the kerf from which it was removed, wet or dry. The reason for the gullet on a tooth is to give the shavings somewhere to be while they are removed from the kerf. On my circular sawmill it is possible to "hang the saw". That is when it is fed fast enough that the gullets fill with chips before exiting the cut and it can stop the mill in a really bad hurry.

Green wood is about half as strong as dry, remember mechanical properties change around the FSP. The reason timberframers and log builders prefer to work with green timber has nothing, at all, to do with quality. It is far easier to work with green timber. A big summer beam back in the day might have a temporary post under it for the first few years as it dried and gained strength in order to avoid a sag in the floor later.

But, what you were describing earlier sounded like a pinch to me.

I was making a planter in the shop yesterday for a Chestnut trial project and managed to turn off the bandsaw and trip over the generator that was in there for repairs. If I didn't break a rib or 2 they sure feel bent this morning. We took delivery of 34' 180 lb trusses at work last week and planned on setting them this coming week. It's gonna be a long week.

|

|

paulz

Member

|

# Posted: 23 Mar 2025 12:03pm

Reply

Thanks DRP and all. That must be what was happening. Laying those 20’ branches across my 4 support jig must have created the binding. I just cut a 2’ section of the same branch in half, no problem. Guess the full days of yard work are really starting to catch up to this old fart.

At least I haven’t tripped over a generator. Yet this week. Good luck with the rib recovery.

Funny story, thinking of which. Some years ago we went on a river rafting trip with friends. We put my disabled wife in the center of the raft. Down the river a piece we hit rough water. The guy piloting fell and knocked her into the water. No emergency situation but he did crack a couple of her ribs when he fell on her. She’s well over it but won’t let him ever forget!

|

|

| << . 1 . 2 . |