| . 1 . 2 . >> |

| Author |

Message |

alex_rousseau

Member

|

# Posted: 24 Jul 2023 12:01pm - Edited by: alex_rousseau

Reply

Hi.

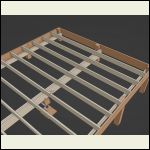

Inspired by Bushradical's Off Grid Cabin in the Woods videos, we decided to build a cabin of our own on a lot we own in SE Quebec (similar climate to Northern Vermont).

Some specs:

- base (rim/end joists) dimensions : 16' x 12'

- wall heights: 10' (front) / 8' (back)

- posts : 6" x 6" PT

- rim/end joists : 2" x 10" PT

- floor joists: 2" x 6"

- studs: 2" x 4" 16" OC

- roof rafters : 2" x 8" 12" OC

- roof covering : sheathing + membrane + metal

- wall covering : sheathing + isoclad + smartside wood panels

In the videos, the PT posts are buried in soil. We preferred to not do that to prevent long-term rot.

Instead, this is what we have ...

The terrain is sloped (see side view #2).

Post heights are 39" (front), 25" (mid), 19" (back).

The 3 front posts sit on a 24" x 24" flat stone resting on 12" of gravel. The other posts (mid and back) are supported by square concrete blocks, each block also resting on 12" of gravel (see close-up #4).

However, this stuff is clearly heavy (I am guestimating the no-load weight of the completed project at a minimum of 5,000 lbs) and all sorts of questions come to mind, self-doubt has set in and I wish I had planned this better.

Questions such as ...

- Are eight 6" x 6" posts strong enough to support that much weight, given that the rim and joist supports are all nailed sideways into them?

- Also, aren't untethered front posts and concrete block supported mid and back posts a recipe for eventual disaster (sliding, lifting, toppling, etc) ?

So I'd like to solidify things a bit. I thought I could begin by adding 2 piers (sonotubes) in front that could be support and tie the bottom of the front rim joist but am not sure that this would be enough. Also, for all I know, sturdier, easier to install solutions might exist.

So I turn to this forum : what would you do?

|

|

Nobadays

Member

|

# Posted: 24 Jul 2023 01:18pm

Reply

The first thing that jumps out at me is the rim joist.... is it just fastened to the outside of the 6x6's or are they notched so they bare the weight of the structure and not the fasteners holding the rim joist?

If notched... great! If not a concern. On first glance the rest looks pretty nice.

|

|

alex_rousseau

Member

|

# Posted: 24 Jul 2023 01:38pm - Edited by: alex_rousseau

Reply

The rim and end joists are indeed just fastened to the outside of the posts. No notches of any kind. It all rests on spiral galvanized nails hammered through the joists, into the posts.

So yes, a concern ... or ... not ?

The post tops also act as partial support for the wall frame corners (see image #8 corners and what lies beneath them => rim and part of post).

|

|

Nobadays

Member

|

# Posted: 24 Jul 2023 03:41pm

Reply

I like the way the floor joists rest on top of the "internal rim joist?" A bit unconventional so unsure what to call that. Unfortunately it seems to rely solely on nails as well to supply our floor... are the joist end nailed on the rim joist and hangered?

As built yes the corners would be well supported by your posts but that won't keep the center span from settling, bowing.

There are others on here with A LOT more experience with proper, code compliant building methods.... ICC being the real go-to guy! He will hopefully chime in.

|

|

Brettny

Member

|

# Posted: 24 Jul 2023 03:45pm - Edited by: Brettny

Reply

Its prety difficult to build on 6x6 posts and have them ontop of blocks. You end up needing alot of cross braces going every wich way. Have you thought about just building on filled blocks upto a girter ontop of the block? Then just lay the floor joists right on the girter. No notching needed and no cross braces needed.

Also bushradical dosnt really properly make a foundation when he builds them like that. Hes also typicaly on flat sandy ground.

|

|

alex_rousseau

Member

|

# Posted: 24 Jul 2023 07:01pm

Reply

Nobadays and Brettny, thanks for writing.

Quoting: Nobadays Are the joist end nailed on the rim joist and hangered?

The joists are end-nailed into the rim but they are not hangered. I could hang them -- internal rim joist might be in the way; I'd probably have to use a compact right-angle drive -- and that was in my list of "improvement options".

...

Quoting: Brettny Have you thought about just building on filled blocks upto a girter ontop of the block? Then just lay the floor joists right on the girter. No notching needed and no cross braces needed.

If I understand correctly, you would consider using concrete (2-hole) blocks, stacking them vertically if need be, above the frost line, possibly resting on gravel, with a couple of vertical rebar stems, and then building a girder that would rest on said blocks, the girder in turn supporting the rim and end joists?

Picture = 1,000 words ... brb ...

|

|

ICC

Member

|

# Posted: 24 Jul 2023 09:26pm

Reply

Quoting: alex_rousseau The rim and end joists are indeed just fastened to the outside of the posts. No notches of any kind. It all rests on spiral galvanized nails hammered through the joists, into the posts. So yes, a concern ... or ... not ?

Yes. IMO a big concern.

The first thing that popped into my mind was that the entire vertical load of the building and contents are being supported solely on the nails.

A 16D Common Nail (3-1/2" x 0.162" diameter) has a shear strength of about 140 lbs. If it's a Sinker (3-1/2" x 0.148" diameter) shear is 115 lbs. A Box Nail or the usual Nailgun nail (3-1/2" x 0.135" diameter) has a shear of 100 lbs.

Notches into the pier sides would be much better. The rim would then be supported directly by the post and the nails would just be holding the rim flat against the post. Beams sitting on top of the piers would be even better.

That 16 foot center 2x10 (is it a 2x10, same as the rims??) with a post at either end is not going to support much floor weight. That floor could very well have some unwanted bounce.

The joists that are end nailed without any hangers are a very weak point. Having the second inner rim helps with that but again, everything is hanging in the strength of the nail shear.

The piers sitting on top of the grade level are also a weak point. If there is a stiff wind blowing against one of the sides what is keeping the building from being pushed sideways? A few nails. Piers set into the ground can resist such lateral forces. What you have cannot resist much. The nails you have are again a weak point.

|

|

Brettny

Member

|

# Posted: 25 Jul 2023 06:24am

Reply

Quoting: alex_rousseau Picture = 1,000 words

Like this but you can use concrete blocks and not sono tubes if your not going below frost and building on blocks. If useing blocks I would use two per level. You can also see how the girder is on the top of the concrete and the floor joists are ontop of the girder. This means the strength isnt hardware dependant.

|

|

|

Malamute

Member

|

# Posted: 26 Jul 2023 08:32pm - Edited by: Malamute

Reply

You can improve your rim joist to post fastening with lag screws or machine screws (bolts) and nuts with washers to pinch/clamp the rim to the posts better.

Im not an engineer or deal with code specs, but 1/2" or larger diameter hardware is probably appropriate.

|

|

alex_rousseau

Member

|

# Posted: 26 Jul 2023 11:58pm

Reply

Thanks everyone for this. You have given me much to think about (and a slight case of the frights...) . I'll be posting the corrections I am thinking of making in the hope that they will be sufficient to lower the red flags.

Thanks again.

|

|

alex_rousseau

Member

|

# Posted: 26 Jul 2023 11:58pm

Reply

Quoting: ICC That 16 foot center 2x10 (is it a 2x10, same as the rims??)

Yes it is.

|

|

alex_rousseau

Member

|

# Posted: 28 Jul 2023 03:20pm - Edited by: alex_rousseau

Reply

Thanks to your advice, am about to :

1. notch down-slope rim joist support posts and attach with through bolts (see rim support image)

2. hang (with Simpson or equivalent joist hangers) all floor joist extremities on their respective rim joists

3. still not sure how to best do this : add support for mid-slope 2x10 (the one supporting the middle of the floor joists) as there was some bounce -- at this early stage -- when jumping on subfloor.

|

|

Brettny

Member

|

# Posted: 28 Jul 2023 04:33pm - Edited by: Brettny

Reply

Bolting into vertical 6x6 posts will still allow them to rack.

You typicaly get rid of a bouncy floor by adding more supports. In this case more blocks. With only useing 2x6 for a 12' span you will need to add a whole other support beam under all the joists. If you want a solid floor I would beef up the 2x6 joists to a 2x10.

|

|

alex_rousseau

Member

|

# Posted: 28 Jul 2023 05:39pm

Reply

The 2x6 floor joists did+do have a mid-length 2x10 under them. That cross joist is screwed into the mid-slope posts.

Would supporting that in its middle (hence at middle-center position under the floor) with a post and footing be necessary ?

|

|

alex_rousseau

Member

|

# Posted: 28 Jul 2023 05:40pm - Edited by: alex_rousseau

Reply

I can't seem to be able to upload images.

|

|

alex_rousseau

Member

|

# Posted: 28 Jul 2023 06:06pm - Edited by: alex_rousseau

Reply

v2 of base

|

|

alex_rousseau

Member

|

# Posted: 28 Jul 2023 06:20pm - Edited by: alex_rousseau

Reply

Quoting: Brettny Bolting into vertical 6x6 posts...

Actually the bolts are only there to attach rim to posts. The bolts do not have anything to do with the floor joists. My illustration misled you. Sorry.

The floor joists would be hanged (via joist hangers) on the rim joists, hence would be supported by both hangers _and_ the 3 cross members.

|

|

ICC

Member

|

# Posted: 28 Jul 2023 06:53pm - Edited by: ICC

Reply

I have a problem with a few things. Take that center 2x10 that is supposed to help support the floor and whatever contents and people there are present.

That center 2x10 will be bearing 50% of the total floor load. IF this was a normal home we would use 40 PSF as the load and build to prevent sag and bounce. That would make a 3880 lb load on the center 2x10. But this is a cabin and maybe we can assume no piano, no huge refrigerator. I arbitrarily dropped the load from 3880 lbs to 2500 lbs. (26PSF).

Then I calculated deflection on a 2x10 #2 S-P-F 'beam'. I come up with a deflection (sag) at the centerpoint of 1.66". That is over an inch more of the desired deflection of 0.53". And that is not even looking at the strength of the fasteners used to connect the ends of that 2x10 to the two posts.

A good solid center post and footing would reduce the deflection for that 26 PSF reduced floor load to 0.21",( in the center of each of the resulting 8 ft spans) even less than the calculated desired minimum of 0.27". So that would be great, but how will that support be adjusted if/when the soil shifts?

|

|

alex_rousseau

Member

|

# Posted: 29 Jul 2023 12:03am - Edited by: alex_rousseau

Reply

Quoting: ICC A good solid center post and footing would reduce the deflection for that 26 PSF reduced floor load to 0.21", even less than the calculated desired minimum of 0.27". So that would be great, but how will that support be adjusted if/when the soil shifts?

I am tempted to replace the 2x6 floor joists by hanged 2x10s but ...

I am worried that removing the cross supports -- necessary to make way for the new joists -- would place too much of a burden on the end-nailed 2x6s waiting to be replaced.

I could always pre-hang the 2x6s, then remove the 3 cross supports, then:

1. unhang one 2x6

2. replace it with a 2x10

3. hang the new 2x10

4. rinse and repeat (11 times)

It's probably safer but it _is_ a lot of work and I am wondering if that is not overkill.

|

|

ICC

Member

|

# Posted: 29 Jul 2023 09:03am - Edited by: ICC

Reply

What species of wood are sold as the common construction lumber where you are? That affects sizing vs loads..

If you have hem-fir grade 2 available 2x10 can span the 12 feet without a center beam.. using 40 PSF 2x10 hem-fir can span 15'2" with proper support at each end.

Doug fir 15'7". Southern pine 14'

IMO center beams should and can be avoided in 12 ft wide buildings , especially those that will likely need releveling.

It is all a lot of extra work at this point because the design has flaws, IMO

|

|

Nobadays

Member

|

# Posted: 29 Jul 2023 09:05am

Reply

Maybe double up a center 2x10 to support the 2x6 joist, then dig in a center support concrete pier.... with an adjustable bracket to account for shift/settling. One way or another it seems you need to support the floor joist. You appear to have enough crawlspace to get under there and dig a hole for a center support. Expense wise this would be more cost effective.

|

|

alex_rousseau

Member

|

# Posted: 29 Jul 2023 09:24am

Reply

Quoting: ICC It is all a lot of extra work at this point because the design has flaws, IMO

It sure does. I should have done more research. Yet another life lesson ...

This cabin is in SouthEastern Quebec (adjacent to Northern Vermont). Lumber is typically SPF #2.

The CMHC's span tables indicate that 2x10 SPF 16" OC lumber can span a maximum of 13 feet, which has me covered. However, no indication of deflection is indicated. Is there a (online) tool you would recommend for such calculations?

|

|

alex_rousseau

Member

|

# Posted: 29 Jul 2023 09:47am

Reply

Quoting: Nobadays Maybe double up a center 2x10 to support the 2x6 joist, then dig in a center support concrete pier.... with an adjustable bracket to account for shift/settling. One way or another it seems you need to support the floor joist. You appear to have enough crawlspace to get under there and dig a hole for a center support. Expense wise this would be more cost effective.

I would like that but the ends of that doubled-up joist would only overlap with the side joists by 4 inches.

Now, the single joist ends are nailed into the mid-slope posts. Doubling them up would probably require some other means of connecting doubled-joists to frame.

doublesupport2x10.jpg

|

base4.jpg

|  |  |

|

|

ICC

Member

|

# Posted: 29 Jul 2023 02:54pm - Edited by: ICC

Reply

I am not aware of any online deflection calculator, however there is an online solution.

But first, if the table data is for floor joists, then the deflection factor that is being used should be L/360. That is standard and is the minimum required for installing ceramic tile (over a min of 3/4" sub floor and a 1/4" layer of cement fiber backer board.) L/360 should result in a satisfactory floor. However, at times with longer spans resonance can enter the picture as people walk across a floor. A bounce can sometimes occur but is hard to predict as that can vary between a lightly loaded and a heavier loaded floor.

That L/360 means we take the span distance of the floor joist, in inches, and divide it by 360. The result is the expected deflection at the joist center, with the PSF load spec's in the table. Load is 40 PSF in all rooms except sleeping areas, which can be 30 PSF.

So, 144/360 = 0.4".

The AWC joist & rafter span calculator indicates 15'5" as max span for #2 S-P-F 2x10 @16" OC and LL 40 PSF. Canada and US values could vary a bit in the data they use for the timber commonly available.

The AWC calculator is very handy with versions for PC, Android and iOS. It has two modes; max span for a single member and span options in which you can enter several species and desired span with the results displaying the joist sizes that will meet the requirement.

https://awc.org/resource-hub/?gcat=calculators-tools

Their Connection Calculator is also quite good.

There is a tutorial from AWC. https://awc.org/publications/tutorial-for-understanding-loads-and-using-span-tables/

And a handy deflection limits table available for download here... https://www.google.com/url?sa=t&source=web&rct=j&opi=89978449&url=https://www.iccsafe .org/wp-content/uploads/bcac/IRC-R3017.pdf&ved=2ahUKEwj_4O7OyrSAAxVxhe4BHZNlAaAQFnoEC BMQAQ&usg=AOvVaw10Ua8PZvVEISYiNevpYmry

Screenshot of results screen of Android span calculator...

|

|

Grizzlyman

Member

|

# Posted: 30 Jul 2023 08:01pm - Edited by: Grizzlyman

Reply

Thinking through your options… if I had to either dig a new footing, possibly pour a footing, post, etc… or just swap the 2x6s for 2x10s. I’d do the 2x10s. That seems much easier… would take an afternoon to get done.

Maybe more expensive but I’m sure you’ll be able to reuse the 2x6s somewhere else throughout the project

|

|

Brettny

Member

|

# Posted: 31 Jul 2023 07:31am

Reply

I would also use 2x10s for the floor joists. 2x6 just have no business being a floor joist. They need so much support that it's more worth while to just get taller lumber.

|

|

toyota_mdt_tech

Member

|

# Posted: 31 Jul 2023 08:43am

Reply

How about leave it all as it is and just run a girder down each end to hold the ends of the floor joist up, girder large enough with post going down to footers. So the load will go through the girders rather than the screwed down inner joist support. Add a midway girder too for the deflection.

With floor underside all sheeted, this seems to be a simple solution.

|

|

gcrank1

Member

|

# Posted: 31 Jul 2023 09:16am

Reply

Its a 12x16 cabin, not unlike a 12x16 prebuilt shed.

How about you put down some cement pads (ie, silo blocks) and stack some blocks up to that center beam.

From time to time you can crawl under and re-shim if needed.

|

|

alex_rousseau

Member

|

# Posted: 2 Aug 2023 02:32pm - Edited by: alex_rousseau

Reply

Thanks again for all your feedback. It has been really helpful.

I have decided to switch to or supplement with 2x10s PT floor joists and I have considered 2 options.

Option 1

Note : I estimate weight of floor and current loads (ladder, some scaffolding, a few tools, subfloor panels) at 500 - 1 000 lb.

Hang the existing 2x6 floor joists (they are presently only end-nailed into the rim joists). Because each joist is end nailed to the rim joist with two 16d galvanized ardox (spiral) 3.5" nails, my calcs (22 nails, 1000 lb. of floor load) indicate that hanging the 2x6s might be superfluous. Does this make sense?

Then, remove the cross joists that were supporting them from underneath.

Then, next to each 2x6, hang a 2x10. Because each joist hanger is appr. 3.5" wide, the 2x10s would be appr. 4" (leaving a bit of space between adjacent hangers) away from the 16" OC marks (over which the 2x6s are currently centered).

This option can be done relatively quickly but it adds appr. 150 lb. of dead weight (132 linear feet of 2x6) to the structure.

Option 2

Replace the 2x6s by hanged 2x10s.

This requires a lot more work :

- removing subfloor screws,

- slicing adhesive present between subfloor panels and 2x6s to avoid damaging the panels,

- removing cross supports safely,

- replacing each 2x6 by a 2x10 while trying to minimize damage to the glued subfloor panels,

- etc.

I will go for option 1 unless someone can spot a risk with that approach.

Thanks !

|

|

alex_rousseau

Member

|

# Posted: 2 Aug 2023 02:58pm - Edited by: alex_rousseau

Reply

Quoting: ICC The AWC calculator is very handy with versions for PC, Android and iOS. It has two modes; max span for a single member and span options in which you can enter several species and desired span with the results displaying the joist sizes that will meet the requirement.

Sadly, the app is buggy (crashes upon calculate button action). Will signal this to the devs.

Thanks for the other info, too. It's been very useful.

|

|

| . 1 . 2 . >> |