|

| Author |

Message |

Cedar Fever

Member

|

# Posted: 10 Sep 2022 06:11pm

Reply

So my cabin is close to the top of a hill. It get a lot of wind. It has already moved, and I need to get it secure. Its super super rocky terrain.

My best bet so far has been to get these oil pipes shoved four feet into the ground. Now I need to attach some chains to them.

I was going to bolt an eye bolt to the pipes. I am not good at drilling metal and am not sure that is feasible.

I dont know how to weld at the moment.

Anyone have any ideas? See anything I am missing or is it time to read up on drilling metal or welding?

cabin_pipes.JPG

|

tie_down.JPG

|  |  |

|

|

ICC

Member

|

# Posted: 10 Sep 2022 06:46pm - Edited by: ICC

Reply

Drilling metal requires good drill bits and possibly a lubricant. It might help if you told us what your past problems were in order to best help.

Drill pipes are often thick walled enough to be drilled and tapped for bolts can be threaded into the walls. Drilling through and using long bolts is okay too.

If you don't weld and have no real reason or desire to learn how to weld just skip that.

Pipe hanger clamps would work. link to an example They have a threaded boss that is used to thread in the hanger bolt. Use that for an anchor point.

I would have placed the pipes closer to the walls and angled them with the bottom ends directed under the cabin.

You have discovered why a foundation should be securely fixed into the ground, not simply sitting on the ground. Plus the building beams, them joists should have all been secured to one another and the foundation.

|

|

toyota_mdt_tech

Member

|

# Posted: 10 Sep 2022 08:06pm

Reply

Are you saying the ground is erroding or is the wind sliding it on the blocks?

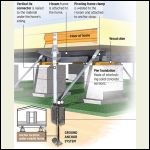

Get those mobile home anchor metal straps.

mobilehome1.jpg

|

tiedown2.jpg

|  |  |

|

|

Irrigation Guy

Member

|

# Posted: 10 Sep 2022 08:14pm

Reply

Maybe use these

|

|

Cedar Fever

Member

|

# Posted: 10 Sep 2022 10:20pm

Reply

Thank you everyone for the advice so far.

I know this foundation is a hot mess. I will spend more time improving it than it took to build the entire cabin. Live and learn. I am planning out sistering the floor joists. And the skids could be better. Tried to find someone to put it on I beams, no luck so far.

I am not to keen on trying to get new spikes into the ground until I use these pipes first. These pipes are drilled three foot into bedrock. From what I have seen digging around I would not get more than 10†trying to get an auger into the ground.

When I drilled that hole I broke 1 bit, and dulled two more. Was getting some binding that was twisting the drill badly. I’m looking at some kind of better drill bit but I am sure my technique of drilling metal like it was wood did not help.

|

|

travellerw

Member

|

# Posted: 10 Sep 2022 10:53pm

Reply

If you are drilling just mild steel (like oil pipes), then let me suggest cobalt bits. Grainger and Amazon sell cobalt bits. They cost more, but chew through the material at a shocking rate.

Be careful and drill as straight as you can as cobalt bits are more brittle. However without a drill press its the best way to drill mild steel in situ!

|

|

paulz

Member

|

# Posted: 11 Sep 2022 12:23am - Edited by: paulz

Reply

Drilling through curved surfaces frequently sticks and breaks bits as the cutting edges break through unevenly. I'd use a unibit (stepped bit) with small increments. And keep the pressure on, overheating will work harden the metal.

You could also cut a slot in the top of the pipe, drop the chain down inside and slide the proper link into the slot.

|

|

Irrigation Guy

Member

|

# Posted: 11 Sep 2022 07:09am

Reply

I am assuming that it is 1†pipe and that all the pipes are threaded at the top. Thread a coupling on the pipe, get 1/2†threaded eye bolt with two nuts and washers, get 1â€x3/4†threaded bushing, put eyebolt through the bushing and install washers and nuts to hold it tight, thread the bushing into the coupling on top of the pipe. Now you have an eye firmly attached to the top of the pipe with no drilling.

|

|

|

Cedar Fever

Member

|

# Posted: 11 Sep 2022 08:57am

Reply

The pipe is in the 2-3 inch range. The outside diameter increases where the threads are.

|

|

Cedar Fever

Member

|

# Posted: 11 Sep 2022 09:04am

Reply

Quoting: paulz You could also cut a slot in the top of the pipe, drop the chain down inside and slide the proper link into the slot.

That is an outstanding idea. Not sure how to pull it off but that would simplify this build.

|

|

gcrank1

Member

|

# Posted: 11 Sep 2022 09:28am

Reply

Less 'elegant' but you can make a chain loop around the pipe and use a repair link to join it to itself.

|

|

rpe

Member

|

# Posted: 11 Sep 2022 09:29am

Reply

Quoting: Cedar Fever That is an outstanding idea. Not sure how to pull it off but that would simplify this build.

Yes, slotting that pipe sounds like a great idea. A cordless angle grinder with a thin metal-cutting abrasive disk will do the job easily. I'd suggest slitting it so the chain sits below the threaded area. Then clean up the threads a bit with a file, and thread a pipe cap on top to secure the chain and reinforce the top a bit.

|

|

paulz

Member

|

# Posted: 11 Sep 2022 12:10pm

Reply

Quoting: rpe Then clean up the threads a bit with a file, and thread a pipe cap on top to secure the chain and reinforce the top a bit.

Good idea. If you don't have an angle grinder just make two cuts with a hack saw the width of the chain, bend the middle down and hack off at the bottom.

|

|

toyota_mdt_tech

Member

|

# Posted: 11 Sep 2022 12:37pm - Edited by: toyota_mdt_tech

Reply

Quoting: Cedar Fever The pipe is in the 2-3 inch range. The outside diameter increases where the threads are.

Pipe and tube are measured differently, tubing is outside, ie building a roll cage for a car, while pipe is measure on the inside. So a 2" pipe will measure 2" on the inside and larger on the outside depending on wall thickness. So a 2" pipe with 1/8" wall or .125 wall will measure 2 1/4 OD

|

|

spencerin

Member

|

# Posted: 11 Sep 2022 03:46pm

Reply

ICC's idea is great. Probably the easiest and cheapest solution, not to mention the least likely to screw up.

|

|

Bruces

Member

|

# Posted: 12 Sep 2022 07:17am

Reply

Using a grinder ,grind a hole an inch or so down the pipe ,and another on the opposite side .Drop your chain down the middle ,then place a bolt through one hole ,through a chain link ,through the other hole and stick a nut on it .Same can be accomplished with a drill but you seem to have difficulties drilling and a grinder will make quick easy work of the job .

|

|

|