| . 1 . 2 . 3 . >> |

| Author |

Message |

paulz

Member

|

# Posted: 1 Jul 2022 09:26am

Reply

I have the carport I'm building out of left over lumber almost ready to sheath the roof, 10 manufactured 2x4 trusses I got free a long time ago on 4' centers. I have 1x pine boards for sheathing, and metal roofing to go over that.

The pine boards are 10" wide. If I use them like that, I have only enough boards for a 12" space between them. I can rip them in half and cut the spacing in half. Thinking it doesn't matter much once the metal roofing goes over it, or does it?

Also thinking I'll use up the leftover rolls of tar paper I have over the sheathing.

|

|

Tim_Ohio

Member

|

# Posted: 1 Jul 2022 09:51am

Reply

I know this is a carport, but you may still have condensation form on the underside of the tin where it is exposed (if I understand your construction completely). I'm under the impression you will have spaces between the 1x pine boards to be used like purlins. The problem with the tar paper is that it may sag between the boards or space between the purlins.

You might consider a rigid foam board as thin as possible to put under the tin first.

If there were no spaces, tar paper would seem to be the right thing to do.

Tim_Ohio

|

|

paulz

Member

|

# Posted: 1 Jul 2022 10:06am

Reply

Thanks Tim. Yes you understand correctly. I've been thinking the stapled tar paper would keep from sagging, maybe not. Smaller gaps between the boards (purlins I guess) would reduce that at least.

I thought my old house, years ago, had skip sheathing with tar paper and shingles. It might have had wire running under the tar paper but too long ago to remember.

|

|

Brettny

Member

|

# Posted: 1 Jul 2022 10:37am

Reply

Typical metal roofing only needs a perlin every 2ft and it definitely dosnt need to be 10in wide. I may even rip those 10in boards into 3 pieces.

|

|

paulz

Member

|

# Posted: 1 Jul 2022 10:58am

Reply

Thanks Brett. I'm envisioning having to walk on it, either while screwing down the metal or later on to make repairs etc..

Do they typically walk on this type of roof, or maybe lay down a sheet of plywood over the perlins while installing the metal?

Thinking back again, I'm pretty sure my old house roof had wire running over the perlins to support the tar paper. I could do that, but being a carport regular bailing wire would probably rust, maybe some galvy wire.

|

|

Tim_Ohio

Member

|

# Posted: 1 Jul 2022 11:20am

Reply

I think I'd just give up on the idea of tar paper, if it's not supported somehow. You will be happier. Since air can get to the underside and it will be the same temperature for the most part, on both sides, you will have little trouble with condensation. However, there might be a "perfect storm" of weather that might cause a bit, but not very often. I'd not install it since it's open on both the top and bottom.

Tim_Ohio

|

|

Tim_Ohio

Member

|

# Posted: 1 Jul 2022 11:23am - Edited by: Tim_Ohio

Reply

Also, it's best to stay on the perlins when you walk it. The tin will support you, but at the possible cost of denting it or damaging it. Also, I hate to bring this up, but there is an ongoing argument as to how to fasten it. Some will say on top of the rib, some will say on the flats-next to a rib. I've always done it on the flats, next to a rib. The rubber washer under the screw seals really well. The ones I used actually had a cupped washer that contained the rubber one, and the screw was only to be torqued enough to take the cupped washer to the surface....stop!

|

|

paulz

Member

|

# Posted: 1 Jul 2022 11:54am

Reply

I have a bucket of those rubber washer screws, plan to put them in the flats. It's been really satisfying using up all this leftover material, haven't bought a thing yet. Lumber, joist hangers, hurricane ties, lag bolts..

If I can get the perlin spacing down to under shoe size I can walk on it without missing a perlin. I have no other use for the boards, might as well use all of them.

Tiring work for this 65 year old. Half day of ladder work about does it. Still lots of summer left to finish.

|

|

|

Tim_Ohio

Member

|

# Posted: 1 Jul 2022 12:07pm

Reply

I moved to a new/old house recently and those "65 year olds" I've befriended have been kicking my butt.

We all run and bicycle in serious ways and I'm impressed with them. The 70's crowd around me is in on it too. I'm 58, and they are all just staying in such good health, I'm just envious. I'm still working and, and "so it goes", and trying to stay fit for all of the projects on the "to do list". Good luck on your project.

|

|

paulz

Member

|

# Posted: 1 Jul 2022 03:27pm

Reply

Same here, there's a group of runner/cyclist health nuts older than I that go all day. I've never had that kind of endurance. Years ago when I did that sort of exercise it just made me more tired the next day.

I'm subscribing to the David Crosby school of longevity:

https://www.youtube.com/watch?v=ZoehKrQ95Iw&ab_channel=jerbilvideo

|

|

paulz

Member

|

# Posted: 2 Jul 2022 10:41am

Reply

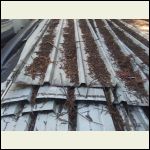

Here's the mess I'm making. So the metal roofing has a full rib on one side, with a small flat edge, and the other side not quite a full ridge. The partial ridge overlaps the full ridge I take it. At the gable ends, do I run the purlins (and the outermost truss, which I can move) just to the end of the last flat part and let the last ridge hang free?

These panels are 25' long, half will go on each side. I have this crazy idea that instead of cutting them fully in half I will just cut through the ridges and flop them over the top and let them bend at the flats, still connected.

20220701_180814.jpg

|

20220701_104707.jpg

|  |  |

|

|

toyota_mdt_tech

Member

|

# Posted: 2 Jul 2022 05:29pm

Reply

Paulz, yes, the small section overlaps, do you have an anti siphon groove on there on either side of the area where it overlaps? How steep in the pitch? Some require a sealant and small stitch screws, these are the short hex headed ones. Pay attention to the high wind direction, you want that overlap section to be pointed in same direction as wind is going, not coming from to it wont lift. I doubt with those tall trees if you see high winds, but I'm certain you will see heavy rains.

|

|

paulz

Member

|

# Posted: 2 Jul 2022 06:08pm

Reply

I haven't measured the trusses but not much pitch, 3 or 4 in 12. Good point on the direction, although very wind sheltered there, good rain which the tree canopy turns into large drops. Had to come to the city today to fix a flat tire, will check tomorrow for the siphon grooves.

These used panels do have sealant on them, gooiest, stickiest stuff you ever saw. White colored. Guess I should get some. Thanks TMT.

|

|

Shadyacres

Member

|

# Posted: 2 Jul 2022 06:23pm

Reply

putting extra purlins on is fine. I dont think I would screw to every one if they are close, (foot) fastening on two foot spacing is common. Have fun.

|

|

gcrank1

Member

|

# Posted: 2 Jul 2022 08:16pm

Reply

Imo, the more 'purlins' the better even if it is skip sheathed. I like the idea of as much support as possible in case I need to go topside.

|

|

paulz

Member

|

# Posted: 2 Jul 2022 09:17pm

Reply

I'm not sure what the difference is between skip sheathing a purlins. Maybe skip sheathing is more of a term for a shingled roof, and purlins for sheet roofs, spread farther apart.

|

|

Brettny

Member

|

# Posted: 3 Jul 2022 07:41am

Reply

Quoting: paulz Thanks Brett. I'm envisioning having to walk on it, either while screwing down the metal or later on to make repairs etc.. Do they typically walk on this type of roof, or maybe lay down a sheet of plywood over the perlins while installing the metal?

I have a wood shed with 3/12 the lowest pitch roof useable on metal roof. I used 1x3 every 16in and walk on it. You feel things flex a bit though so I stay to walking on the perlins. Since your building a car port in an area with no snow I would build it like what it is...a sun/rain shade. 1x3 on 24in centers will be fine.

|

|

paulz

Member

|

# Posted: 3 Jul 2022 09:43am

Reply

I think mine is 3/12 also. What's the spacing on your rafters Brett?

|

|

paulz

Member

|

# Posted: 3 Jul 2022 01:05pm

Reply

What nails would be best for this 1x pine into the rafters?

|

|

toyota_mdt_tech

Member

|

# Posted: 3 Jul 2022 08:07pm

Reply

Quoting: paulz These used panels do have sealant on them, gooiest, stickiest stuff you ever saw. White colored. Guess I should get some. Thanks TMT.

Yes, you can get it in rolls. You will need it at the end of the metal roofing where the gable trim wraps around and seals to it also.

To town to fix a flat? I alwasy fix my own flats now, never even go the the cabin without flat repair gear and my 6 gallon compressor.

Tire repair kitURL

And replacement gooey ropesURL

You can get full kit and spare plugs from walmart too.

|

|

toyota_mdt_tech

Member

|

# Posted: 3 Jul 2022 08:10pm

Reply

Paul, pay attention to screw pattern. Get fatter screws, they are in 2 foot spacing from each row. Get them perfect, or if you stand back, its so noticeable.

You need the flatter pan head screws if you do flashing over the rafter tail ends, stitch screws for the overlap and stitch screws are also used for the ridge cap.

|

|

paulz

Member

|

# Posted: 3 Jul 2022 08:39pm

Reply

Quoting: toyota_mdt_tech To town to fix a flat? I alwasy fix my own flats now, never even go the the cabin without flat repair gear and my 6 gallon compressor.

It's a split rim, inner wheel on a dually, my fire truck, going in the parade tomorrow. My fault, I neglected to check, hard getting the gauge in there. So it went flat, the tire spun on the rim and pulled the tube stem in. Like wrestling a bear getting it apart and back together but the tube was fine. I have a tire machine back at my city house to break the bead.

Yeah I plug tires here, no problem.

20220702_180924.jpg

|

20220701_1810311.j.jpg

|  |  |

|

|

Nobadays

Member

|

# Posted: 4 Jul 2022 08:06am - Edited by: Nobadays

Reply

Quoting: toyota_mdt_tech Paul, pay attention to screw pattern. Get fatter screws, they are in 2 foot spacing from each row. Get them perfect, or if you stand back, its so noticeable.

I know you are using re-claimed metal so the existing screw pattern on those will guide the placement of your skip sheathing. If you will be drilling new holes.... I've found that if I stack the sheets even on the ends then pre-drill to match my sheathing spacing you can get really straight screw lines, plus it makes starting the screws a piece of cake when you're up there on the roof.

|

|

paulz

Member

|

# Posted: 4 Jul 2022 10:04am

Reply

Thanks Nobs, yes it's time to lay all these panels out and check how big and where the screw holes are so I can make sure to have wood underneath them.

I'm thinking I need 8D galvy nails for the 1x perlins. Hopefully i can get the Passlode gun to work one more time, finicky thing. Sure don't want to hand nail or drag an air hose around up there.

|

|

Nobadays

Member

|

# Posted: 4 Jul 2022 02:34pm

Reply

Quoting: paulz I'm thinking I need 8D galvy nails for the 1x perlins.

Definitely galvanized.... I always use ring shank on skip sheathing. Might be over kill but I feel safer.

|

|

paulz

Member

|

# Posted: 4 Jul 2022 04:58pm

Reply

Sounds good. Spent some time ripping boards this morning, then off to the 4th parade. They were only 9" wide, not 10", so I cut them in half. I have 7 more boards that are 11" wide, might go thirds on those depending how far these get me. Not sure I ever worked with pine before, cut like butter on the table saw.

20220704_103233.jpg

|

Screenshot_2022070.png

|  |  |

|

|

Brettny

Member

|

# Posted: 6 Jul 2022 06:45am

Reply

Quoting: paulz hink mine is 3/12 also. What's the spacing on your rafters Brett?

16in rafter spacing and 16in perlin spacing. I screwed the perlins down. It's only a firewood/tractor shed but I screw everything that's not studs or sheet goods. Part of this shed was a wood shed at family members house that was screwed together 20yrs ago. Because it was screwed together it's easy to take appart.

|

|

paulz

Member

|

# Posted: 7 Jul 2022 07:23pm - Edited by: paulz

Reply

Yeah on 16" rafter centers walking on it would be much safer than my 4' centers. I laid out a test today, looks like I'll be somewhere between 12 and 16" perlin centers, 4.5" wide perlins.

I'm going to cut my 25' metal panels in half. They are galvanized steel, maybe 20 gauge.

What is the usual way, carbide wheel on a circular saw?

|

|

paulz

Member

|

# Posted: 7 Jul 2022 09:32pm

Reply

Just watched a video where the guy put a carbide tipped wood blade on backwards and cut metal roofing.

|

|

darz5150

Member

|

# Posted: 7 Jul 2022 11:34pm - Edited by: darz5150

Reply

Quoting: paulz Just watched a video where the guy put a carbide tipped wood blade on backwards and cut metal roofing.

I've done it with air shears, nibblers, snips, cut off wheels, concrete saws and with a carbide blade turned backwards on a worm drive saw. Don't know what you saw on the tube.

All will work. If you had just a few cuts or harder cuts, like for stove pipes/vents, the cut off wheel works pretty good. But if I have a lot of cuts. I grab the worm drive. It will chop it in short order.

You have a concrete saw. That might work best for you.

We used to cut metal soffit on a jig, all the time with the reverse blade method.

|

|

| . 1 . 2 . 3 . >> |