| . 1 . 2 . >> |

| Author |

Message |

SCSJeff

Member

|

# Posted: 19 Mar 2019 02:50pm

Reply

Hi all,

Bit of background... We use our cabin for hunting during the hunting seasons and ATV'ing during the summer. (We have direct access to about 80 miles of ATV trails).

It's becoming a real PITA loading up my trailer full of the family's ATVs/UTV and dragging it back and forth several times a year (sometimes not even worth the effort). I was thinking it would be nice to be able to leave the machines at the cabin.

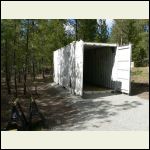

So... I have an opportunity to obtain a 20' shipping container from my work for free. It's in pretty good shape. Would just need to patch a few pin holes in the roof. My only cost would be moving it. My cousin has a roll back and would just have to pay him about $350 in fuel.

The drawback of course is that it is not especially esthetically pleasing

I guess in my mind, I thought I could paint it initially and then maybe, over time, clad it with wood panelling and build a timber frame roof over it to make it look more like a traditional shed.

It would be great secure storage for the machines and maybe more importantly be rodent proof.

Just wondering what everyone's thoughts were???

|

|

justins7

Member

|

# Posted: 19 Mar 2019 03:35pm - Edited by: justins7

Reply

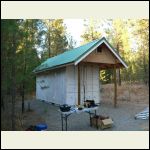

I was on track to get a 20' shipping container for my cabin land, but ultimately decided to go with a pre-fab mini-barn.

Two reasons: ventilation and aesthetics. Since this was going to be used for storage, I realized that the containers are a hot metal box that really needs to be vented well. (I've read many stories of people experiencing water inside raining down on their tools, if not vented.) This is not that big of a deal to do, but it adds to cost and time. Then there's the fact that I would need to do a lot to make it blend in with the landscape (thinking of future salability of the property). So I wound up buying a pre-fab wooden structure and decided to put more effort into security monitoring.

I do love the idea of a more secure steel building, though.

So obviously you have to balance cost, with storage temps/venting, and looks (and how much time and money you can devote to it).

Do a search on the forum for shipping containers — there's been a lot of discussion on the subject.

|

|

toyota_mdt_tech

Member

|

# Posted: 19 Mar 2019 03:41pm - Edited by: toyota_mdt_tech

Reply

Quoting: SCSJeff The drawback of course is that it is not especially esthetically pleasing

Then you are doing it all wrong. Oh, a Battery Tender solar charger will keep the batteries fully charged too on your ATV's.

The roof also keeps temps inside stable, I added 3 vents on each side, 3 down low on one side, 3 up high on the other side, stable temps and no sweat.

container_painted_fr.jpg

|

container_painted_fr.jpg

|

container_painted_fr.jpg

|

container_painted_re.jpg

|

|

|

justins7

Member

|

# Posted: 19 Mar 2019 04:52pm - Edited by: justins7

Reply

That's fantastic.

(Exactly what I wanted but I didn't have the time or resources.)

|

|

Princelake

Member

|

# Posted: 19 Mar 2019 04:59pm

Reply

Tons of people in my area have them as sheds. Quite a few ppl have 2 shipping containers apart from each other and build a roof typically trusses and have storage in between like a 3 bay garage. They do get hotter then a typical wooden shed but adding some type of whirly bird or vent could solve that from. Make sure they are well sealed cause bees love making nests in them and you have a bottom skirting cause rodents love living under them. If your in a snowy climate make flaps or covers for locks cause theres no protection for locks freezing up

|

|

Steve961

Member

|

# Posted: 19 Mar 2019 06:01pm

Reply

As toyota_mdt_tech has shown, sometimes all you need to make a shipping container more aesthetically pleasing is to add a roof. It also greatly helps in keeping the temperature down inside. And if you're going to add a roof, you might as well have it do double duty and provide some extra space to park your ATV's under when you are there.

|

|

toyota_mdt_tech

Member

|

# Posted: 19 Mar 2019 11:43pm - Edited by: toyota_mdt_tech

Reply

I might add, my total cost was around $5000, this was for the container, the move twice (from auction yard to cousins place, then lots of welding, filling holes, adding vents, welding on brackets to support roof, then to final resting spot) then building roof over it (no OSB, all plywood) and then metal roof and paint job.

It sets on about 6 yard of crushed rock as a foundation. All those forklift slots you see have a secure screen fitted inside to keep varmints out.

Also, no taxes as its just a container settign on the ground. And its 8'6" wide by 20' deep, that puts me under the 200 foot square footage max to avoid permit.

|

|

sparky30_06

Member

|

# Posted: 20 Mar 2019 06:47am

Reply

make sure you have a good level base to set it on, when they shift the doors are a pain to open.

For longer life raise it up so you can get airflow under it.

With a little creativity you can make it blend in very well.

|

|

|

SCSJeff

Member

|

# Posted: 20 Mar 2019 08:11am

Reply

Awesome Responses everyone!

Toyota, that looks great. I'm going to show that to my wife so she can feel a bit better about it

I am aware of the condensation issues. And I certainly don't want the inside of the container raining on my machines. I found this: https://360productsnorthamerica.com/node/164 was planning on installing these passive vents.

Do I need to care if critters can live under it? (I suppose it's possible they could eat through the floor???) Of course, we have lots of rattle snakes and they keep the mice at bay. But, surprisingly there are still lots of chipmunks running around.

I have a stone pad already where it can sit (just like Toyota's). Would I still need airflow under it then?

|

|

toyota_mdt_tech

Member

|

# Posted: 20 Mar 2019 08:23am

Reply

Jeff, critters under it wouldn't hurt anything unless they became DRT under it (dead right there) and the smell,. that was my concern.

Mine is vented nicely, never sweats, the roof has made the temps more stable, the roof is vented with 2 vents at each and (12"X12") and vents between each rafter (qty 3 2 inch holes in each) so the attic breathes nice. There is a crawlspace access to attic in the overhang area.

I laid out thick bed of gravel for base, about 8 to 10" thick, packed and leveled. When the container was dropped, a 6 foot level was dead center both ways. A 20 footer wont flex like a 40 footer does. Mine has zero movement, the thick gravel base keeps it stable.

P1020801.JPG

|

P1020807.JPG

|

P1020830.JPG

|

P1020870.JPG

|

|

|

toyota_mdt_tech

Member

|

# Posted: 20 Mar 2019 08:29am - Edited by: toyota_mdt_tech

Reply

And of course, the finish product in brown.

I welded brackets onto the roof then secured 4X6 on it with timberlocks, see the black paint, that is where it was welded. I also filled in holes witht he welder, had items bolted to skin and added the vents. The vents are baffled to keep from looking inside and a roof over it to keep water out. 3 low on one side, 3 high on the other. There is places that make vent kits for these. You could insulate the rafter ties to keep it even cooler, mine is pretty stable inside with never a drop of moisture. My might vary depending on humidity in your area. But proper venting and roof can cure it.

My support post for overhang was out enough for doors to clear, but if I open the doors flush with post,. gets me max room.

I certainly could of done it cheaper, but I am way to picky to just plop down a container. It had to look first class. Note, no OSB. I hate the stuff.

The ribbing along the sides allowed me to build a shelf area across in the back and key the support 2X4 studs on the back and sides inside the valleys, then once the shelves were added, it was locked in place and I did it with no holes drilled. There is anchor points all along the top and bottom for securing cargo, great to hang ladders off after making hooks to hang in the loops.

All the black spots is paint over a welded up area, it had a few holes in it. Along the top was welded brackets, no holes in the roof.

P1020872.JPG

|

P1020873.JPG

|

P1020880.JPG

|

P1030004.JPG

|

|

|

SCSJeff

Member

|

# Posted: 20 Mar 2019 08:58am

Reply

That's some great workmanship there Toyota!

Certainly beyond my skillset... But, this will get me storage on the cheap fast and I can work on making it look nice over time and as money permits.

BTW: I sent your finished pic to my wife and she replied: "Yes, Do it!!!"

|

|

Brettny

Member

|

# Posted: 20 Mar 2019 11:28am

Reply

I looked into a 20' for our property. Ultimately i can never get a 40' trailer to fit in the driveway and thats what it would be delivered on. Also im to close yet to far from the port so would have to buy site un seen. I also dont like the look and prob wont be an asset if/when i go to sell the property.

Yet for free and $350 delivery on your familys roll back i think you cant loose!

I chose to go with a 10x14 real wood shed. Roughly the same sqft and will pay $2800. A 20' delivered with a 40' trailer that wont make it on the property would be $2300. I cant set it in the proper place and make it not look like a shipping container for $500. This is alot of reason why i went the wood shed route. I will still need to spend some money making a shed more secure and rotent "proof"

|

|

SCSJeff

Member

|

# Posted: 20 Mar 2019 01:29pm

Reply

Brettny,

You nailed it... When I was originally looking into a shipping container, I didn't think it was going to save me any money over a traditional shed (in the end). However, for only the fuel costs of transporting, I don't think I can pass it up.

|

|

toyota_mdt_tech

Member

|

# Posted: 20 Mar 2019 03:37pm

Reply

Quoting: SCSJeff But, this will get me storage on the cheap fast and I can work on making it look nice over time and as money permits.

Jess, they make vents kits you can buy and sawzall in and and bolt them down as for the boards along the top to build roof too, just lay a 4X4 or a 4X6 like I did and you can drill and bolt them to the roof of container. I used 4X6 because of the gap of overhang to the support post.

Mine has 5 locks (American model 700 with 6 pin tumblers all keyed alike and hardened 7/16" hasp, 4 on doors and one 5th one in lockbox not accessible. You can buy all this stuff that bolts on too. So makes it super secure. I have other security features I wont mention in here.

|

|

justins7

Member

|

# Posted: 20 Mar 2019 04:57pm

Reply

Toyota, I am truly envious of the work you did. It looks amazing! And it looks like it will last into the next millennium. Bravo!

... And I want to know about the other security features!

|

|

SCSJeff

Member

|

# Posted: 21 Mar 2019 10:44am

Reply

Toyota,

What paint did you use for the container and how did you apply it?

Thanks,

Jeff

|

|

sparky30_06

Member

|

# Posted: 21 Mar 2019 11:40am

Reply

SCSJeff

Jeff, where are you located?

|

|

SCSJeff

Member

|

# Posted: 21 Mar 2019 02:12pm

Reply

sparky,

I'm in Central PA

|

|

toyota_mdt_tech

Member

|

# Posted: 22 Mar 2019 08:36am - Edited by: toyota_mdt_tech

Reply

Quoting: SCSJeff Toyota, What paint did you use for the container and how did you apply it? Thanks, Jeff

Jeff, it was covered already in a white epoxy paint, was super tough stuff, had to grind through it to weld and that was even tough, it was a green layer under the white. I used Behr Premium Ultra, we sprayed and rolled it. First coat was white primer. I rolled over it to hide the numbers/stickers that was on it and it filled in real nice and after several trips around it, all hidden. Color applied, was N150-7 Chocolate Therapy for you guys who want that USFS or state park look.

If it was bare metal, I'd probably of used an oil base, but it had a good undercoat and water base is a snap to clean sprayers and painting tools, especially way out off grid.

Quoting: justins7 And I want to know about the other security features!

Justin, drop me an email, my user name in here @ yahoo dot com

I check it once a month, not my normal email, but I will fill you in.

|

|

sparky30_06

Member

|

# Posted: 22 Mar 2019 10:34am

Reply

Central PA, you must have them timber buzz worms over there

|

|

paulz

Member

|

# Posted: 23 Mar 2019 10:06am - Edited by: paulz

Reply

I've had a 20 footer for about 6 years now next to my cabin. It now has a deck built on top of it.

It's well vented, in fact I usually leave the doors open, however all my tools inside suffer corrosion over the winter. Both my cabin and another wooden shed I built last year don't seem to suffer this condition. They are both sealed up fairly tight. Another prefab shed I have down the hill also is fine, and it has a metal roof and is well vented. Something about that storage container..

0713161013.jpg

|

0826181337.jpg

|

0404171255.jpg

|  |

|

|

toyota_mdt_tech

Member

|

# Posted: 23 Mar 2019 06:21pm

Reply

Add more vents, some high, some low on opposite site or add a whirly bird. You need more moving air and inside and outside temps close to the same.

|

|

SCSJeff

Member

|

# Posted: 25 Mar 2019 09:58am

Reply

Quoting: sparky30_06 you must have them timber buzz worms

I don't think so... At least not that I'm aware of. I had to Google what they even were  Never seen anything like that Never seen anything like that

|

|

SCSJeff

Member

|

# Posted: 25 Mar 2019 10:02am

Reply

Hah, nevermind  , Monday morning.... , Monday morning....

I don't know what Google was showing me... Some kind of strange bug...

Then I woke up and realized what you meant... Yes, lots of RattlerSnakes around my cabin. More than once was warned by the "buzz" as I approached my power shed to turn on the solar. That would be the only negative of having the shipping container elevated off the ground...

|

|

toyota_mdt_tech

Member

|

# Posted: 30 Mar 2019 07:25pm - Edited by: toyota_mdt_tech

Reply

For those who do not have access to a welder, you can set a 4X4 along the top, drill holes through the container and use large bolts with large washers to secure it in place.

I would imagine those square washers used for sill boards on top of foundations.

I would use the large square washers on the inside metal and on top of the 4X4. I would run the bolt up from inside the container, with the nut on top of the 4X4. This will work for those who dont have a MIG welder etc. The top is ribbed, drill bolt holes on the high spots (peaks not valleys as viewed from outside) and just use typical rafters with a rafter tie and collar ties.

I used 2X6 for ridge, rafters, rafter and collar ties and even fascia boards. Spaced at 24"

|

|

SCSJeff

Member

|

# Posted: 30 Mar 2019 10:15pm

Reply

Toyota,

Thanks for the info on using bolts.

However, can the pockets on each corner be used in some way to attach the runners to without drilling holes in the roof?

|

|

toyota_mdt_tech

Member

|

# Posted: 31 Mar 2019 12:17pm - Edited by: toyota_mdt_tech

Reply

Jeff, it would be tricky, the hole is large and no flange for a washer. With a nut welded onto flat bar sticking out the keyhole, its doable, but would be weak in design and no support for the top plate board mid way.

I did plug the top of my keyholes on mine inside on the top with a chunk of wood, but left the sides open, its a perfect spot for a nice secure birds nest or not so good, maybe a bees nest.

The reason I mentioned drilling holes into the peaks as viewed from the top would put the holes on the high spots, so even if you had a roof leak, water would not come though bolt holes. The roofline is ribbed, like the sides, smaller scale, they do this for strength. The sheer weight of the roof should hold itself in place and rafter ties would hold the top plate (as we will refer to it here) from bowing out. Maybe not hurricane forces.

|

|

SCSJeff

Member

|

# Posted: 31 Mar 2019 12:23pm

Reply

I see what you're saying now... Regarding the bowing. ie: Still need something in the middle to support it.

Thanks!

|

|

Steve961

Member

|

# Posted: 31 Mar 2019 04:52pm - Edited by: Steve961

Reply

I would avoid running bolts through any of the container walls/roof if at all possible. The best place to secure bolts to is the top box beam. As long as you only drill through the outside wall of the box beam, and keep the bolts short enough, the interior wall will remain intact and prevent any water from ever entering. I have a shipping container waiting to get a roof built on it this summer, and I plan to use plates similar to those in the picture below.

.

|

|

| . 1 . 2 . >> |