|

| Author |

Message |

Made in MT

Member

|

# Posted: 30 Jan 2019 01:58pm

Reply

Hi, I'm very new here so please be kind if I'm not using the correct terminology. I am adding on to my cabin this summer with a 11x14' foot print. After hours and hours of educating myself have decided on flat log anywhere form 8" to 16" high and 6" thick wall construction and dovetail corners.

My question: I have a sawmill that only allows 11' long logs and I need as mentioned 14' but cant seem to find a good way to join the logs end to end. Can someone help please, thanks in advance!

|

|

darz5150

Member

|

# Posted: 30 Jan 2019 02:57pm - Edited by: darz5150

Reply

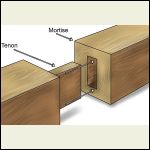

Scarf joint. Mortise and tennon joint.

Scarf joint

|

Mortise and tennon

|  |  |

|

|

ICC

Member

|

# Posted: 30 Jan 2019 03:25pm

Reply

Can you redesign the 14 foot wall length to have a window or door to break up the 14 foot length? I would hate to try to end join two wall heights worth of logs. Seems like an overabundance of work for something that will likely look like a patch job forever. Cut and add in a section of bed for the sawmill? That has been done before. Some mills have bed extensions made for them.

|

|

rockies

Member

|

# Posted: 30 Jan 2019 07:50pm

Reply

I take it you mean that the logs are flat on all four sides?

You're going to have a weak wall if you include splices in the length of the log. The strength comes from the interlocking of the dovetails at the corners.

What you may consider is the "Swiss technique" sometimes called Bohlenbau.

The principle, however, is very simple. You have a vertical post in the middle of the wall with a vertical groove cut in it that then receive tenons on the end of the infill timbers. It is important that these horizontal timbers be free floating, and also that they not be relied on to bear structural loads due to the different shrinkage rates of vertical and horizontally oriented wood.

An update to the technique would be to instead cut the grooves on the ends of the horizontal timbers, and have them join to a "cross shaped" post. This allows the posts to retain more structural integrity, as cutting grooves in them can lead to excessive splitting.

|

|

w8n4rut

Member

|

# Posted: 31 Jan 2019 08:08am

Reply

Hi Montana-

Sounds like you are building very similar to me. I am limited to 10'-6" for my log length because of my sawmill. Also I am working alone a lot of the time so I had to keep the logs manageable. I am also milling my logs square mostly 9" tall by 6" wide.

I have lots of windows and doors to keep horizontal joints to a minimum but will still have some. Just make sure to stagger joints in the wall so you can anchor the joints good with your logs above and make sure to distribute the bearing points throughout the wall. Much like in conventional framing when you would stagger your top plate over your lay-out plate joint. Also make sure to span over the window and door headers with your log so you don't have a joint above just like in conventional framing.

For the horizontal joints that I do have I am incorporating a type of a dovetail joint in the wall to tie it together and to shed water/ air. I don't have a pic handy but will try to post a pic later for reference.

Just curious what you're using for a mill?

Good luck with your build and post pics/ updates if you can!!

Tim

|

|

w8n4rut

Member

|

# Posted: 31 Jan 2019 12:32pm

Reply

This is just what I came up with because I am in a similar situation looking to eliminate water/ air issues when the log shrinks and moves.

Here is a mock up of what I am doing. Wide end down so any moisture that gets in outside joint will flow out. The logs will shrink minimal in length as opposed to height and width. Also not shown in the pics is the gaskets and caulking between coursed used when installing the logs.

*Disclaimer*

This is a scrap piece of log with holes and punky in places that I would of used in interior application or ripped into 1x stock not used in exterior wall.

horizontal log joint 1

|

horizontal log joint 2

|  |  |

|

|

w8n4rut

Member

|

# Posted: 31 Jan 2019 12:36pm

Reply

A couple of more pics.

horizontal log joint 3

|

log course profile

|  |  |

|

|

Old and Slow

Member

|

# Posted: 31 Jan 2019 01:50pm

Reply

First question- is this a butt and pass using D logs? Which means logs lay directly on top of the next lower log as shown in w8n4rut's pictures or is this a traditional cabin build with logs only touching in the corner?

For butt and pass this is not a problem. Butt them together at different places, drill a hole in the butt joint and insert a dowel with caulking.

If this is a traditional notched cabin with logs only touching in the corner Rockies's vertical post is one answer. Otherwise logs can be joined with a scarf joint by cutting to half thickness and overlapping with fasteners. This seems to me to be a weaker approach.

|

|

|

w8n4rut

Member

|

# Posted: 31 Jan 2019 02:33pm

Reply

Quoting: Old and Slow Which means logs lay directly on top of the next lower log as shown in w8n4rut's pictures

Yes this is what I assumed.

Tim

|

|

rockies

Member

|

# Posted: 31 Jan 2019 07:16pm - Edited by: rockies

Reply

The one thing you are forgetting is lateral movement. The strength in a log wall comes from the corners being interwoven with the side walls. If you create a seam in the middle of the log wall from using shorter log lengths the wall could bow out at that point.

In the old days people would "jog" the wall over (by maybe 2 or 3 feet) so that the perpendicular wall between the two could act as a brace (it creates a "Z" shaped wall on the plan). If you don't want to do that then you will probably have to brace the center of the wall from the inside using a beam or maybe a floor joist.

|

|

old243

Member

|

# Posted: 31 Jan 2019 09:22pm

Reply

Is there some one in the area ,with a mill with a longer bed , that would square the logs for you. Would save a lot of patching and joining. Or at least do your logs that are longer than your bed. I have a bandmill, have found that as the logs dry . they tend to twist especially if the heart of the log is in the middle. I cut a bunch of spruce 8x8 . Let them sit stickered and well covered for 2 years. I had to remill them and true them up. , mostly twist. probably lost 1/2 inch per face. You might want to consider this , as a possibility.. I ended up resawing them , and built with stick framing. A mill extension would also work. My mill will do 20 feet, if necessary. Have fun with your project. old243

|

|

|