| . 1 . 2 . >> |

| Author |

Message |

Mushroom Man

Member

|

# Posted: 16 Apr 2017 12:54pm - Edited by: Mushroom Man

Reply

I'm ready to move on from the foundation to the subfloor. However I was hoping to get some advice regarding the floor insulation. Doing insulation UNDER the subfloor can be very labor intensive. I have heard about laying the then insulation on top of the subfloor then laying your floor boards on top of it.

Flooring underlayment protects against moisture and reduces cold floors with thermal insulation. The one I'm looking at is 2mm thick with an R-Value 4 per inch.

If I do go with this underlay then it will insure no critters can climb up into my subfloor insulation.

Can I get some real life experience advise???

Thank you.

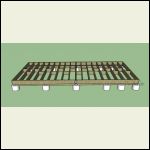

measurement_6.jpg

|

measurement_7.jpg

|

measurement_8.jpg

|  |

|

|

bldginsp

Member

|

# Posted: 16 Apr 2017 04:46pm

Reply

Underlayment goes on top of the plywood, the insulation is under. It won't stop critters. It reduces moisture that gets to the flooring

To keep critters out of the insulation, you either have to make a tight perimeter or cover the bottom of the joists.

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 04:50pm - Edited by: Mushroom Man

Reply

bldginsp

Oh...what I was saying is;

Instead of using insulation between the floor joist could I just use underlayment as the mane insulation that goes ON TOP of the subfloor but under the wood floors. Bypassing the risk of critters crawling into the insulation and saving time and $?

|

|

Just

Member

|

# Posted: 16 Apr 2017 05:17pm

Reply

I am leading a small 9 x 12 on skids next month . Our plan is to build joist frame first then cover it with P T 1/2 in plywood then flip the whole thing over and add the insulation and subfloor could be a

fun we are 4 strong..

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 05:47pm - Edited by: Mushroom Man

Reply

Just...sounds cool. You are lucky to have help. I'm doing this by myself. I'm thinking I will put screening, like chicken wire, under the floor joist (staple) while I place each 2x4x10' joist into their brackets. If I take my time it shouldn't be too taxing on me.

|

|

DaveBell

Moderator

|

# Posted: 16 Apr 2017 05:53pm

Reply

What is the R-Value required for your location?

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 05:55pm - Edited by: Mushroom Man

Reply

DaveBell

I have no idea. I'm close to Cincinnati, Ohio though.

However I did find the insulation that I will propably use: Owens Corning R30 31.25-sq ft Unfaced Fiberglass Roll Insulation with Sound Barrier. It is also a vapor barrier.

|

|

DaveBell

Moderator

|

# Posted: 16 Apr 2017 06:00pm

Reply

Quoting: Mushroom Man I'm looking at is 2mm thick with an R-Value 4 per inch

2mm = 1/16 inch.

R Value of 0.25.

Not sure that is money well spent.

|

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 06:02pm

Reply

DaveBell

I don't think so either. I'm going with a full insulation. No I have to find out how I'm going to lay it between my floor joist. I have to make sure it stays in place and protect it from critters getting into it.

|

|

DaveBell

Moderator

|

# Posted: 16 Apr 2017 06:11pm - Edited by: DaveBell

Reply

Foil faced insulating board, foil down, on 1x1 PT strips nailed inside joists. Expanding foam to seal. Trapped air is your friend. The foam spout clogs up so do all the strips first, cut all the boards, place and squirt. Wood is the poorest insulator, so lean towards pic 1 spacing above.

Your on the cusp of zone 4 and 5.

Ceiling 49

Walls 20

Floor 19 zone 4, 30 zone 5.

Start reading the 2009 IRC online.

If you rip PT 2x4's, you can get a ripping blade for your table saw. (wear a mask, try to stay up wind) PT dust is poisonous.

A cross cut blade has angled teeth left to right, a ripping blade teeth are straight across, left to right.

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 06:14pm - Edited by: Mushroom Man

Reply

DaveBell

EXCELLENT ADVISE!

Wow! Thank you very much!

|

|

rockies

Member

|

# Posted: 16 Apr 2017 06:25pm - Edited by: rockies

Reply

Insulating a floor over piers is a big pain. You typically have to crawl under the cabin to nail sheathing against the bottoms of the floor joists or else find some way of laying plywood on top of your beams and building the floor system on top of that (and still crawl underneath to fasten the plywood in place). Then it's vapor barrier, insulation and then subfloor.

Are you planning on putting any plumbing in the floor system because that will indicate how much insulation you'll need (and even then there is still the risk of pipes freezing).

Would you like to know a simple method of building the floor? Contact a supplier of structural insulated panels and buy some that are at least 10 inches thick. Have them cut out the foam at the edges so you can install the edge framing lumber on site. Lay the panels on top of your beams, screw them down and then seal the seams between the panels. it's a fast, easy solution because it's structure, insulation and vapor barrier all in one product.

If you do want to add plumbing to your cabin build a false floor on top of the panels and within your exterior walls. That way all the pipes are contained inside the building envelope and have a much lower chance of freezing.

The price of floor panels should be around $8 a square foot.

|

|

DaveBell

Moderator

|

# Posted: 16 Apr 2017 06:31pm

Reply

Two inches is R-10. Why 10 inches Rockies? He only needs four inches.

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 06:32pm - Edited by: Mushroom Man

Reply

DaveBell

I'm having a hard time finding Face insulation board. Any suggestions?

Well this work? https://www.lowes.com/pd/Kingspan-Insulation-R1-Faced-Polystyrene-Foam-Board-Insulati on-Common-0-25-in-x-4-ft-x-50-ft-Actual-0-25-in-x-4-ft-x-50-ft/999972970

I would do as you suggest but place the Wool Batt Insulation on top?

|

|

rockies

Member

|

# Posted: 16 Apr 2017 06:34pm - Edited by: rockies

Reply

Because the panels are also structure. You'll have much less flexing of the floor (depending also on the spacing between the support beams) but if he chooses to also use batt insulation inside the false floor system then he could go to an 8 inch thick SIP panel.

Try contacting these guys in Columbus Ohio. The panels you'd need are probably the simplest design for them to make, just square 4x8 panels. You might as well get a quote.

http://www.lamitindustries.com/

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 06:36pm

Reply

rockies

Researching info.

Thank you!

|

|

DaveBell

Moderator

|

# Posted: 16 Apr 2017 06:42pm

Reply

https://www.menards.com/main/building-materials/insulation/insulation-panels/johns-ma nville-foil-faced-polyiso-foam-insulation-2-x-4-x-8-r-13/p-1444438919949.htm

Google foil faced rigid insulation.

Both HD and Lowes can get stuff not on the floor.

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 06:44pm - Edited by: Mushroom Man

Reply

DaveBell

I was trying to stick with Lowes however....Menards will do nicely!

You just saved me time and $$$ with this insulation idea.

PS...WOW! That is expensive!

Thank you!

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 06:54pm - Edited by: Mushroom Man

Reply

DaveBell

I am confused about one thing. Does Floor R-value 30g mean R-Rating 30? Just want to be on the same page.

Thank you.

|

|

DaveBell

Moderator

|

# Posted: 16 Apr 2017 07:02pm - Edited by: DaveBell

Reply

Floor R-19 for zone 4, R-30 for zone 5.

From the map is depends on which county the cabin is in. Zone 4 or 5? But since the wall requirement is 20 for both zones, I don't know why you couldn't meet a 20 for the floor. Call your county inspectors office and tell them your in the planning stage and ask.

Expense. Yep, but there are long term rewards for doing it better. Like not having to stuff the wood stove four times a night. You may be able to put in a medium size wood stove, burn it down to a bed of coals, re-stuff it, and dial down the vents to get an all night burn. Search for wood stoves here and read the discussions.

I'm planning on the Englander 1800 one at Home Depot that has the external air vent for a 36x22 cabin. Contact the manufacturer for smaller. The external air vent draws outside air into the airbox instead of cold air from around doors and windows.

Also, I have never heard of any good stories about that horizontal tube stove. JulieOregon didn't have much success with it. My friend in GA either. I think its a flawed design in that its dimensions are counter productive to having a good bed of coals and enough box volume to keep it burning.

Here is a redesign for hunters, looks more stout and dimensional improved. http://survivorcampstoves.com/

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 07:07pm - Edited by: Mushroom Man

Reply

DaveBell

I am definitely doing this! I just found a great price on Craigs list.

2.5 inch 4x8- $18 each with R-Rating of 16. However, it is not Faced. Is that an absolute must? Would I be able to adhere something to it?

The person selling it states that it has a white felt paper backing?

|

|

toyota_mdt_tech

Member

|

# Posted: 16 Apr 2017 07:09pm

Reply

IMHO, to keep critters out and have it well insulated, after the floor joist are all in place, I would tack a metal mesh on the underside of the floor joist. You can use an air powered crown stapler and tack it on, either from the direct underside or just inside the joist bays. If you go underside, you can cover many bays with a roll, or just cut strips, tack them just inside the bottom of the joist bays. Cut them long enough to cover the ends of the bays also. This will also hold your floor insulation in place, install it with faced side down. You will have great insulation and great critter barrier. Then lay floor sheeting on over top of joist to cover it all in.

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 07:13pm

Reply

toyota_mdt_tech

I'm thinking about going with the Board insulation. Cut 1x1 PT strips nailed inside joists. Expanding foam to seal. No Rock Wool insulation at all. I think that is my plan.

|

|

DaveBell

Moderator

|

# Posted: 16 Apr 2017 07:16pm

Reply

Quoting: Mushroom Man Would I be able to adhere something to it?

Don't know. Call the manufacturers like Johns Manville and ask them what adhesive they use for the foil face. Then I imagine you could use the 4-inch roller/pan, and heavy foil from the store.

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 07:20pm

Reply

Thank you DaveBell and everyone else that assisted me with this.

I'm going with DaveBell for sure! I have found good board insulation as low as $9 on Craigs list. I'm set!

Thank you!!!!!

|

|

toyota_mdt_tech

Member

|

# Posted: 16 Apr 2017 09:46pm

Reply

What are you doing to keep the mice out?

|

|

Mushroom Man

Member

|

# Posted: 16 Apr 2017 10:01pm

Reply

Hey toyota_mdt_tech

I'm only going to be using board insulation (no wool insulation). The first board, which only has an R-3 rating, has an aluminum face...which will be facing down to the ground. On top of that will be another insulated board with a R-17.5 rating. These will be 'edged' with a foam spray insulation from a can from within the floor joist. All of this is elevated about 2' off the ground.

I feel good that mice will not be able, or want, to get in via the insulated boards.

I should have an R30 for my area so I will keep and eye out for more cheap board insulation from Craigs List. All of this insulation I found for a total of $170!!!!

|

|

Mushroom Man

Member

|

# Posted: 17 Apr 2017 10:28am - Edited by: Mushroom Man

Reply

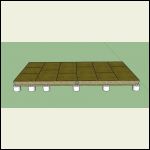

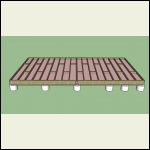

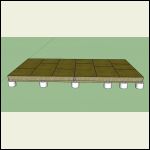

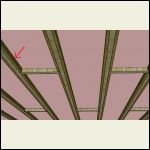

Done with the foundation and subfloor insulation!

I'm nailing 1x2 strips to the bottom of the floor joist to hold the board insulation and sealed down with can spray foam.

I've located board inulation with aluminum face. Total of R20. I'll watch on craigs list for more to raise it another R5 to R10.

Thank you everyone for your input and advise!

Mushroom Man

measurement_10.jpg

|

measurement_9.jpg

|

measurement_11.jpg

|  |

|

|

ICC

Member

|

# Posted: 17 Apr 2017 11:40am - Edited by: ICC

Reply

Rodents can go through foam, foil faced or not like a hot knife. At least the deer mice that live around me can. They can also chew through ordinary chicken wire sized wire, though they don't have to because the holes are large enough for them to walk through.

FYI, mice can slip through a 1/4" space. Mice will be stopped by 23 gauge or thicker mesh with a 1/4" mesh size, or smaller. If you have rats you need 19 gauge mesh. Wire mesh link here https://www.twpinc.com/wire-mesh-by-project/pest-control/rat-mesh and there is a link there to a good exclusuion manual

You're learning about some of the limitations of pier foundations and we haven't even talked about where or not they are stable in the long run, many are not. Maybe I missed that discussion as I haven't been round here for a while but recently. If you must do piers make it high enough off the ground so the bottom of the joists are at least 18", even that is difficult to crawl under. But too tall and they are more unstable, no end of problems.

Build the cabin, get it dried in, the stuff fiberglass or rockwool batts up in there. There are spring wires made to retain the batts up against the floor. Then sheath the bottom with 3/8 or thicker plywood, air nailer comes in handy as does a couple of young men you pay to do that.

And in the second picture above, you have the 4x8 subfloor panels turned the wrong way. Turn them 90 degrees so the long dimension of the panels are parallel to the long sides of the floor. Stagger all the joints, never have a point where all 4 corners meet. When you do that remember the T&G thing

|

|

drb777

Member

|

# Posted: 17 Apr 2017 12:15pm

Reply

I used 1" R-Max (HD/Lowes) between the floor joists, as shown in the picture. 'Takes quite a bit of time to fit each piece, but well worth the effort. BTW, I simply used 12 penny galvanized brad nails below the R-Max to keep it flush to the top edge of the joists.

To complete, my flooring consists of 3/4 T&G (as shown), then 20 mil PE, 2mm foam underlayment and laminate. Very solid, quiet and practical.

floor insulation, subfloor T&G

|  |  |  |

|

|

| . 1 . 2 . >> |