| . 1 . 2 . >> |

| Author |

Message |

TomChum

Member

|

# Posted: 12 Feb 2011 12:30pm - Edited by: TomChum

Reply

I'm on the lookout for a "guest cabin" because my little family completely fills up my 12x16 cabin (in the winter). We could tolerate more people but not their "stuff'', like coats, bags, food, books, toys, boots, gloves, helmets,,,,,,,, or pets.

It's more tolerable in the summertime when you can spend most time outside. But anyway, friends always feel more welcome when they can close the door on "their own stuff" or their own mess.

It's solid wood, except the floor is plywood, and it does use GluLam beams.

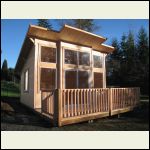

Check this out, $7520 kit for a 12x16 (deck is extra). http://www.mighty-shed.com/

I'd be very interested to hear if anyone has this kit, and how it went. They also do a gable roof version. This company is part of "Pan-Abode" which has been making cabin kits for many years.

============

Here's the materials list:

Price Includes Treated Floor Joists. Plywood Floor, Skids

Pre-cut 2x6 T&G SPF Solid Walls Timber w/ Glulam Columns, 36" Roof overhang,

2x6 T&G SPF Roof Decking on Glulam Wood Roof Beam

30 Year Black Composition Roof Shingles

Vinyl Sliding Glass Door System & Vinyl Windows per Plan

Western Red Cedar Exterior Trim Package, Glue & Fasteners

============

Also this is a pretty economical, and FAST way to get a livable cabin.

Mighty Shed 12x16 "CABANA", with deck (extra)

|  |  |  |

|

|

hattie

Member

|

# Posted: 12 Feb 2011 01:26pm

Reply

That is a beautiful cabin. I like the sloping roof and lots of windows. Face that south and you'd probably never have to heat it on a sunny day. *S*

|

|

TomChum

Member

|

# Posted: 13 Feb 2011 11:24pm

Reply

Quoting: hattie Face that south and you'd probably never have to heat it on a sunny day.

Hey now there's an idea - Cabin on a TURNTABLE foundation. I wonder what it would take to rotate a cabin into-or-out of the sun, based on the season. Maybe rotate it with a come-along (or winch). It might take less effort to turn the cabin than to gather and cut firewood, and in the summer, the shade would be welcome.

|

|

MikeOnBike

Member

|

# Posted: 14 Feb 2011 11:40am

Reply

Rather than turning the cabin it would probably be easier to build a pergola out front and cover it with greenhouse cloth as need to control the solar gain on the windows.

|

|

TomChum

Member

|

# Posted: 14 Feb 2011 07:13pm

Reply

Quoting: MikeOnBike Rather than turning the cabin it would probably be easier to build a pergola out front

party pooper! ..... ;-)

More detail in a reply from Mighty Shed. I asked them the size and weight of this kit ---->1.5 tons.

=============

Weight on the MC1216 is around 2900#. The kit is about the size of 2 chords of wood. 4x4x14 feet, and the large sliding glass door is in a separate box.

=============

|

|

MikeOnBike

Member

|

# Posted: 14 Feb 2011 07:31pm

Reply

Quoting: TomChum party pooper! ..... ;-)

Sorry, being too practical. I have made many design/style compromises because of fire/theft/utilities/weather issues that it drives me mad sometimes. I really want to build something with distinctive design but I keep getting beat down by practical issues.

It does look like a cool building. If you can get by without insulation and won't get too much solar gain from the windows it could be a winner.

|

|

goatworks

Member

|

# Posted: 15 Feb 2011 12:12am

Reply

I've seen these... They have a solid wood system made from car decking. All the pieces come pre cut like a big erector set. Better than sticks and plywood

|

|

MikeOnBike

Member

|

# Posted: 15 Feb 2011 12:56pm

Reply

I like sticks and plywood. It creates cavities to put insulation in. We have too much temperature variation, both hot and cold to have an uninsulated cabin.

If you don't need the insulation it could work well.

|

|

|

goatworks

Member

|

# Posted: 16 Feb 2011 12:23am

Reply

add some rigid foam insul and furring. rigid is way better than batt. I think the idea is that the cabin kit is designed for easy assembly with all the pieces precut. walls are finished done when you put it up. sticks and plywood are passe

also who wouldn't heat a cabin in the woods with out a wood stv. Infiltration is more important than insulation unless you heatin w/ sterno

|

|

TomChum

Member

|

# Posted: 16 Feb 2011 12:30am

Reply

Quoting: MikeOnBike If you don't need the insulation......

Maybe just use a bigger stove?

Quoting: goatworks walls are finished done when you put it up.

That is a cool benefit too.

|

|

MikeOnBike

Member

|

# Posted: 16 Feb 2011 01:53am

Reply

Quoting: TomChum Maybe just use a bigger stove?

Yes, it really is climate and season of use dependent.

Quoting: TomChum That is a cool benefit too.

Yep, major time saver. My wife and I were just talking about how to finish our shed/cabin. Probably a mixture of tile, sheetrock and wood.

Are you considering the loft version? Those look like they would be fun to put together.

|

|

TomChum

Member

|

# Posted: 16 Feb 2011 11:12am

Reply

Well for me, at this point I am trying to avoid adding another project. This is difficult to do because I like projects and should probably try to relax.

While it would be great to have room for guests, the main reason i posted this is just to show it to other forum members. It looks like it would go up quickly, and seems to be pretty good quality and looks for the price. I would definitely add a loft!

|

|

seattle_bill

|

# Posted: 28 Mar 2011 10:59am

Reply

Wondering whether the stacking horizontal timber wall construction might be less resilient than stick-built in case of a sloping slight that settles a bit.

|

|

TomChum

Member

|

# Posted: 28 Mar 2011 12:03pm

Reply

Yes I bet that could skew all the window openings and doors. You're right that with no shear walls in the structure it would be wise to be able to jack/adjust the foundation to straighten it. And you would have to know how to do this.

|

|

seattle_bill

|

# Posted: 28 Mar 2011 02:56pm

Reply

Yep I was concerned because Mighty Shed told me that they wouldn't build on a sloped site (with their construction services that is). Sure jacking/shimming is always possible (and could be optimized with a supports like mobile homes have) but the question remains whether this style of construction is optimal for a sloped site vs. sticks & plywood. In my case it's an off-grid boat-accessed site where I'm trying to minimize cost and hassle.

|

|

TomChum

Member

|

# Posted: 28 Mar 2011 03:06pm - Edited by: TomChum

Reply

They won't do it because of the risk that you will take them to task if it settles. You can add shear strength to it by putting a sheet of plywood on every wall (in the right places, of course).

If you can build it directly on bedrock that would be pretty safe. If the main floor/foundation could sit on 4 posts it would be fairly easy to make the 4 posts good and strong, If only 4 posts it would be easy to adjust jacks over time if necessary.

|

|

seattle_bill

|

# Posted: 28 Mar 2011 07:32pm

Reply

TomChum,

I realize their concern re: construction is liability not feasibility, but the question remains whether this design is the best choice in sloped-site situation. If you are going to add a sheet of plywood to each wall then that is more overhead than stick-built, where the plywood is there to begin with.

In my case it's the opposite of bedrock - what is commonly called unconsolidated glacial till.

|

|

cabinman

|

# Posted: 8 May 2011 01:54am

Reply

I was just told an idea of making your own glulam logs. Take three two by eights and stack them side by side. Then take the middle one and make it an inch higher. You then have a 4.5 inch thick giant tongue and groove. Glue them together with marine adhesive 5200, like construction adhesive but completely waterproof. Make up a bunch and you have insulation, siding, interior, moisture barrier, framing, etc. All in one. Seems expensive at first, but it's super cheap in the long run. And don't worry about doug fir rotting, doug fir is used for boat hulls. Just don't let it touch the ground and wick up water.

Build up a bunch of glulam tongue and groove logs one day, then stack them together the next. As you glue them together just use galvanized finish nails, because the glue will hold everything together. If you don't believe me, try pulling two boards apart that have been glued together with the marine adhesive, you destroy the boards. A friend made all the logs in 5 hours one day, (already had stemwall built) and the next day framed, glued, and screwd the whole 12 x 16 cabin together in six hours. If you don't have floor joists for the longer span, you have to to a little shear wall brake, like you see every 8 ft of a ban abode so your walls don't bow out in the middle( they would only do this if you had a roof with no ridge, causeing horizontal thrust as the rafter weighs down.

Again, just put three 2x8's together, and raise the middle one 1" higher. Then you have the tongue on top, and a void on bottom. Scarf 1/8 inch off middle one's tongue so you have room for glue so the outside 2x8's set down all the way on each consecutive course.

Remember, crown up and out. Meaning always put the crowns in your boards facing up and out.

On your top two courses at the front, run a ten foot long and then 12 then 14 foot, to cantilever a porch out the front.

Jeremy

|

|

cabinman

|

# Posted: 8 May 2011 02:00am

Reply

http://www.google.com/imgres?imgurl=http://www.ksp.kodiakislanddesign.com/bin/LLCabin .jpg&imgrefurl=http://www.ksp.kodiakislanddesign.com/afognak.htm&usg=__4xPdefS-yjWDyl yeawVCVJmLG64=&h=584&w=888&sz=50&hl=en&start=75&zoom=1&tbnid=K-3LMH67xdNatM:&tbnh=127 &tbnw=169&ei=ijDGTcaoIJP0swPNpMmSAQ&prev=/search%3Fq%3Dsmall%2Bpan%2Babode%2Bcabin%26 um%3D1%26hl%3Den%26biw%3D1280%26bih%3D595%26tbm%3Disch0%2C1738&um=1&itbs=1&iact=hc&vp x=112&vpy=248&dur=1001&hovh=182&hovw=277&tx=125&ty=100&page=5&ndsp=18&ved=1t:429,r:0, s:75&biw=1280&bih=595

it would look like this if you used 2x6's to make up your logs and then did a 3/8 round router on the edge of each board. see how there is an arched cantilever to make the front overhang? it's just longer logs.

Also, once your all framed, go on craigslist to find cheap windows. Bring the windows home, then use figure out where you want them. Draw the dimensions and cut out the holes with a sharp chainsaw. Use marine spar varnish or sichens stain on the exterior. Seriously, you could frame and roof the thing for 3000 or so.

|

|

toyota_mdt_tech

Member

|

# Posted: 8 May 2011 02:15pm

Reply

Quoting: TomChum You're right that with no shear walls in the structure...

One could just sheet the inside with plywood, or sheet the outside with T1-11. That wo uld net you some shear strength.

|

|

TomChum

Member

|

# Posted: 6 Nov 2011 01:34pm - Edited by: TomChum

Reply

Quoting: toyota_mdt_tech One could just sheet the inside with plywood, or sheet the outside with T1-11. That would net you some shear strength.

Yes , but that would (further) call into question the sanity of the person who paid the extra money for a "solid wood cabin kit" ;-)

Quoting: goatworks I believe the wall timbers are glued together so the whole wall is a shearwall on the mighty sheds.

Good point!

|

|

toyota_mdt_tech

Member

|

# Posted: 9 Nov 2011 02:35pm

Reply

Not to mention, in my state, if its built as a cabin, it needs to meet R value on walls, ceiling, floor etc. Now if its under permit size, then you are OK and as long as it doesnt get a permanent foundation. Only advantage I can see if someoen lives far away and wants to have a unit in place in a weekend or two.

|

|

goatworks

Member

|

# Posted: 9 Nov 2011 06:42pm

Reply

Their website says they are targeting under permit size. I know when I do my cabin its gonna have a wood stv. I wont give two hoots about energy Efficiency. Last cabin I had was open stud with cracks around the windows and still a wood stove would burn me out of there.

|

|

Black Horse

Member

|

# Posted: 7 Dec 2011 12:47am

Reply

tagging this.

|

|

Black Horse

Member

|

# Posted: 7 Dec 2011 05:08pm

Reply

cabinman

In this glulam type construction, how do you affix the corner construction of these 'lams?

|

|

TomChum

Member

|

# Posted: 7 Dec 2011 05:41pm - Edited by: TomChum

Reply

Quoting: Black Horse cabinman In this glulam type construction, how do you affix the corner construction of these 'lams?

.....this excellent, well-written information is OFF-TOPIC, thus lost in "Nicest cabin yet $7520...."

I hate to see good info go to waste, and confusing another topic in the process, so created a new thread with a proper title. Hope this is OK....

See----> Construction with GluLam logs (made from 2X8s)

|

|

Anonymous

|

# Posted: 24 Dec 2011 09:36pm

Reply

Kits are a joke and a rip off. We just built ( this year) a 30x30 cabin with loft, to dry it in, was only 6500.00 using all first class windows, doors and lumberand foam insulation. If you have plans or can draw plans, save 1/2 off and buy direct lumber.

|

|

Anonymous

|

# Posted: 24 Dec 2011 11:55pm

Reply

Anonymous, I would love to know your secrets. We are getting ready to buy land and build and this will be my first attempt at this so any halp would be appreciated.

Thanks,

MW

|

|

Erins#1Mom

|

# Posted: 26 Dec 2011 07:56pm

Reply

Anonymous,

30 x 30 for $6,500 with all first class windows, doors and foam insulation! Where on god's green earth is this place? I WANT TO BUILD THERE! Would love for you to post photos but of course that would require you to become a member.

|

|

toyota_mdt_tech

Member

|

# Posted: 18 Sep 2015 01:54pm

Reply

Erin, my lumber pkg for my cabin came to $3750, this gave me a dried in, closed up (lockable) shell. But mine was 16X18.

|

|

| . 1 . 2 . >> |