|

| Author |

Message |

akparajack

Member

|

# Posted: 25 Feb 2012 19:21

Reply

We are finally going to put something up on the parcel of remote land we staked and purchased over 25 yrs ago. Materials will be dropped on an ocean beach via landing craft from Seward Alaska, and then sling loaded via R44 on to the site.

Our 1st structure will be a 20' Intershelter dome. There are multiple reasons why we are choosing this as our 1st structure which I won't go into now. The biggest challenge will be managing and building the foundation.

It requires a 20' pad. The weight of the dome is nothing - only 1100 lbs spread out around the circumference...

I'm looking for suggestions on how best to approach this. 4 x 4 x 12 and 2 x 6 x 12 is gonna be it for demensional lumber as I don't feel we'll be able to manage much more on the difficult terrain - its Coastal Alaska primary growth - wet forest with giant Sitka Spruce, sloped very uneven ground with lots of rock, etc, so you get the picture.

It's a jewel of a spot but not a place to just throw down a bunch of 75lb pyramid blocks... The pad needs to be 20 x 20, but it would be nice to overbuild as much as possible, as any finished and level space (decking),will be super valuable. Again I realize that the span is rather large, but the loading is very small. The goal is to plan a foundation which will cover the span, but be minimal in terms of demensional lumber size (weight), and which can applied to the difficult terrain - keeping in mind that everything must be helicoptered onto the spot for big bucks, and managed by two 55 yr olds (who aren't quite as mobile as we used to be)

Any and all ideas / suggestions will be greatly appreciated!

Thanks

Jack

|

|

Just

Member

|

# Posted: 25 Feb 2012 19:57

Reply

any time you are working in a remote area you should take a invetory of what is there already..look around at some old buildings to see what local materals they used..???? got any pics???? usable rock local wood ??

|

|

akparajack

Member

|

# Posted: 25 Feb 2012 21:04

Reply

There are a couple of cabins on the lake, but they had float plane access very close to their building spots so they are conventional construction. Our parcel has giant Sitka spruce and other spruce of all demensions, but we aren't interested in trying to build with logs at this point. Don't really know yet about rock/gravel possibilities...

|

|

Just

Member

|

# Posted: 25 Feb 2012 21:28

Reply

A chain saw mill will, can, make 1 giant tree into a cabin floor . but you got the drift look around see what you have!!!!

|

|

exsailor

Member

|

# Posted: 27 Feb 2012 12:36

Reply

akparajack,

I thought your domes were something I was familiar with, until I looked up the name. That sounds like a pretty good idea, for your situation. While perusing the website I found this "Due to customer demand we have put together a series of foundation designs and innovative interior layouts for download below. Intershelter also provides consulting and mobile installation services. Click here if you would like a quote." Without them going on site, have you talked to the experts, or downloaded the foundation options? Not knowing exactly what you face on site, I might suggest using any level 20 foot site as your foundation site then putting a deck over any incline. Since you have to pack in material you might use local soil and gravel mixed with concrete for a "soilcrete" foundation pad. I might even be cost effective to dig below frost line and set a foundation ring all the way around. Not sure if just doing a pad or digging a foundation would work with the frost line. I imagine it is pretty deep. Would a foundation pad even hold up with frost heaving? I don't have the answer to that.

|

|

akparajack

Member

|

# Posted: 28 Feb 2012 15:24

Reply

<< It might even be cost effective to dig below frost line and set a foundation ring all the way around. Not sure if just doing a pad or digging a foundation would work with the frost line. I imagine it is pretty deep. Would a foundation pad even hold up with frost heaving? I don't have the answer to that.>>

Thanks for the great reply. Initially we were thinking just building a high load foundation so that we could have the option to disassemble the dome at a later date and put up a larger cabin.

Ok so the initial thinking to build a more conventional foundation meets logistical reality. The idea of building a 28x28 or 24x24 pad via conventional dimensional pressure treated post and beam is just too much. Using 6x6 for post and beam, 2x10 for joist, blocking, and splicing, and 2x6 for decking figures out to over 11300lbs for 16 post and 6500lbs for a 9 post.

We need to be in at or under 6000 lbs which includes the 1100 lbs for the dome. I know this is doable but not like this....Our thinking initially was that we just wanted something simple so we could look forward to not tent camping in that difficult environment, and have a base to start working on other building projects. We discovered the dome and figured we can do that and it would be great. We've figured all the major logistics (landing craft from Seward to the beach and heli sling load onto the site. It's pricey but doable and absolutely worth it if we could end up with that dome on that parcel this summer. We could hire a hand to help and I think the whole thing is not just dreaming. I know there are maybe some new and innovative possibilities along with tried and true ways to deal with the foundation/pad challenge - just gotta figure it out!

|

|

fpw

Member

|

# Posted: 28 Feb 2012 16:44 - Edited by: fpw

Reply

Stack some stones; call it good. Set your main beam supports (for the joists) on screw jacks on the stone. Then, you can adjust if you get a little frost heave.

Here is a link where you can purchsae the jacks:

http://www.loghelp.com/c-40-log-home-screw-jacks.aspx

Or, have someone weld up some all-thread.

You can turn trees on your property into beams pretty easy with a chainsaw mill. Then, you just need a little rigging to move the beams into place.

Screw Jack

|

Chainsaw Mill

|

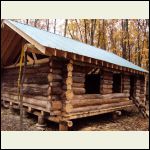

Cabin Supported with Squared up trees.

|  |

|

|

davestreck

Member

|

# Posted: 28 Feb 2012 18:19

Reply

I absolutely agree with using local lumber and a chainsaw mill to get out your beams/joists. In your case, weight = money, and it sounds like you have plenty of usable timber at your site. Remember you only need to square 2 faces anyway, then just peel the bark on the remaining faces. Invest in a ripping chain for your saw (www.granberg.com have everything you need). Plan a few weekend trips to fell and mill timber, and you can have everything cut and ready to go when the chopper arrives. I'd use deck blocks or precast patio stones supporting PT 6x6 posts, which won't rot as quickly as spruce. Spike or lag the beams to the posts and deck it with 5/4 T&G spruce/pine/fir or ply.

My wife and I are building our cabin on a remote offshore island, and everything comes in on our little boat and is then hand carried to the site, so I feel your pain! Keep at it and remember that almost anything is possible with a little (OK, a lot) hard (OK, backbreaking) work.

Good luck.

fpw: great cabin!

|

|

|

akparajack

Member

|

# Posted: 29 Feb 2012 02:44

Reply

Thanks everyone for the excellent replies! Last night was rather discouraging calculating board feet and weight of treated lumber, and seeing how that just wasn't gonna happen....

I'm a bit afraid of not being able to handle trees through the process of felling, moving them around, etc.... but I suppose it's not really a big deal. We have massive amounts of Sitka spruce, some I can't even get my long arms half way around, along with thick stands of 6 to 12 inchers. Green wood is not a problem.

So If we are going to use green chainsaw milled wood for the beams, we could probably afford to bring in nice treated 6 x 6 posts only with some premix and go with a 9 post plan. What about the idea of using nice rounds of green spruce set on level pavers or concrete pads? If it's peeled and treated it's gonna last for awhile? And the whole idea with the screw jacks is to allow us to get away with using green wood for beams or whatever - just adjust the jacks as things dry out and settle?

Is it really feasible to think that we could mill the joist timber with a chainsaw mill? A 2 x 6 I can wrap my mind around but a 2 x 10 or 2 x 12? Perhaps bring in the posts to shore up the foundation, and the decking to kind of clean up after using rough green milled wood for the beams and joists? If we did a really good job on the posts, then if we decided to move the Dome or replace it with a proper cabin we'd already have nice posts to work with.

We have to remember that we're only building a pad to support 1100 lbs of Dome - plus whatever we end up building/adding inside, which probably won't be all that much. Ultimately we just need an elevated platform for the Dome, 24 x 24, but don't have the luxury of flat ground which is the typical installation for the Dome and makes the platform a no brainer....

I did some reading about the frost line, and from what I've read, the frost line doesn't exist everywhere, it's dependent on 3 requirements, a certain amount of silt, the right amount of moisture, and the right amount of temps below freezing. I'm not at all certain that the soil on our parcel will meet the silt requirment.. Does anyone have any insight on this in regards to the Chugach Coast (Little Johnstone Bay) I think the average January temps for that area are in the 20s.....

Thanks again for the help!

Jack & Sue

|

|

Just

Member

|

# Posted: 29 Feb 2012 09:34

Reply

Keep in touch. good luck!!!

|

|

Jerry

Member

|

# Posted: 29 Feb 2012 09:44

Reply

Very interesting and exciting project. It sounds like you are a little hesitant to take on the felling of large trees and turning them into lumber, and I don't blame you. Have you thought about hiring a crew of people with their own chainsaw mill and the experience to make it happen? You might have to provide food and shelter for them on-site for a few days, but for what it costs you might offset your helicopter expenses and end up with a hefty foundation from local resources. Plus, think of the labor it would save you. Just a thought. Good luck.

|

|

fpw

Member

|

# Posted: 29 Feb 2012 16:46 - Edited by: fpw

Reply

If you plan to fell your trees, take the time to learn to do so properly. GOL (Game of logging) provides some excellent instruction on this topic.

Anyone that is remote will be better off if you learn to rig. Especially, when it is time to install the ridge and such. I've found the Army Field Manual on Rigging to be just the ticket...

www.petrospec-technologies.com/Herkommer/knots/FM5-125.pdf

My cabin is a few miles back in the woods, have to skid or make everything, no vehicles. ATV with Log Arch (pictured below) has saved my tail moving things around.

Chainsaw mill works great for beams and flattening two sides. If you want dimensional lumber, your better off with a small mill like a Woodmizer LT-10/15 or TimberKing 1220. I cut 200 square feet of planking for decking with a chain saw mill and decided to get a TimberKing. Very difficult to get it to my site, but worth the effort.

Cutting planks with a chainsaw mill is back breaking work. However, if you have a great deal of time and no funds, then it is that way to go.

Stumps work fine for support (photo below). I dug below the frost line. If I was to build on the grade, I would add in some Screw Jacks so I could level things in the future. As you can see I used oversized planking (cut with a chainsaw mill) set on log joists spaced a good bit apart.

Log Arch

|

Log Arch

|

Foundation

|

Lifting Shear

|

|

|

akparajack

Member

|

# Posted: 12 Mar 2012 00:17

Reply

Time for an update.....

Trying to keep our eye on the immediate goal of a simple level 24 x 24' pad for the Intershelter 20' dome. Very easy to get drawn off that track. We're just building a super beefy big deck. The dome is 320 sq.ft.. Once we have the pad we can assemble it in a day, install the insulation, finish the floor and we're good to go with an amazing structure which is easily heated with screened windows and conventional door, well insulated, bear proof, dry, and made of a very current high-tech aerospace composite material....

It's all about having a place to go so we don't have to rough it in that very difficult environment, and making it happen this summer/fall before the snow flies. Once we're there then things like a portable bandsaw mill, planning and building a log house, planning and building a tree house, installing a pelton wheel water power generation system, building a landing pad for an R44, improving trails, and most importantly, building a zip line from our parcel back down to the lake!

Of course it's all overwhelming, but one step at a time. The weight realities forced us to pull back quite a bit from our first wishful thinking. It's realistic to plan one 6K load on a landing craft from Seward. It's realistic to plan a couple of hours of Hughes 500E time to get the load onto the parcel. These things are done.

Please tell us what you think of our foundation/deck plan so far:

Foundation:

*Concrete piers or any any kind of concrete blocking brought in - no too heavy

* Find onsite sand and gravel, or have it sling loaded from the beach onto the parcel and bring in concrete to mix up our own concrete on site. Then pour footers and use sono tubes, etc... Again, too heavy, too much work, and in our opinion - not really necessary.

Bring in PT 6 x 6s, dig down 4' or to rock, fill with concrete or gravel - again, no too heavy.

Current idea on the table is to use cut to fit pieces of 24" plastic culvert pipe, estimating 24-36" high. Remove organics, pack the culvert with rocks, top it with PT 2 x pieces, then add cut to size green peeled spruce rounds 16-20", then screw jack......

Post and beam:

9 post grid, 10' between posts - green spruce rounds to screw jacks.

6 beams comprised of pt double 2 x 12 x 12s with a 2' cantilever.

Joists:

30 joists including end joists on 24" centers pt 2 x 10 x 12s

Decking:

13 sheets of 4 x 8 3/4" pt plywood, trimmed after install to fit the 20' circumference footprint of the dome. Decking outside the dome circumference finished with pt 2 x 6 x 12....

Add in half inch plywood for the finish floor inside the dome and some extra pt wood for blocking/splicing, and this puts us at about 4000 lbs give or take.

We took a scale to the store and weighed several pieces of PT and found that the weight per board foot was averaging 2 lbs per board foot for everything we tested. The 3/4" pt plywood was 3 lbs per board foot. It's clear that we'll have to take precautions to insure the wood starts the trip dry and stays as dry as possible before the helo hooks up to it.

We're left with 2000lbs for tools, hardware, and all the rest of it, plus another 800-1000lbs which will be available on the inbound leg of the 500E.

So it's a start and we have more questions now then before. Up until now, the biggest issue was the apprehension of the landing craft operators to land in Little Johnstone Bay. Apparently there are some war stories from landings on Big Johnstone next door. Plan B was going to be to take the load around cape Puget to the end of Puget bay where there is a more reliable landing spot. This would make each leg of the sling load several minutes longer, and make things much more difficult and costly for us, but wouldn't be a deal breaker. Then finally a much needed "well duhhh" moment.... Just have the helo sling load the stuff right off the deck of the boat- just pre build the individual sling loads as we load the boat - no need to sweat the landing on the beach if conditions are sketchy

More questions on the table:

Still not clear how to transition from the top of the rock stacked culvert pier to the spruce round. I realize the spruce round can't sit on the rock. Would the best plan be to scrounge up as much smaller rock / gravel as we can on site and pound it into and around the rock at the top of the culvert and just make it as level as we can - and then just lay some pt 2 X pieces down, and then set the rounds on the pt pieces? Would it be better to have some rebar on hand so we could at least drill the bottom of the spruce round and have a piece of rebar buried into the rock stack and up 12"s or so for the spruce round?

Some say we will go down through the organics and find all rock. Assuming you have the right drill / bit, what are the realities of hammer drilling into rock enough so that you can epoxy in some rebar? Doable or a big struggle? If the rock is relatively level, we could place a few pieces of rebar, and then use the same culvert with stacked rock idea?

If the elevation of the beam at a post point is close to the ground, and we find solid rock, can you hammer drill a larger diameter hole - say 3/4", and epoxy in a piece of all thread, and then go right to a screw jack?

If we need a post on sloped rock - what are the options?

OK I should stop now! Thanks for the help and if you have any suggestions please [img=null]don't hold backnull[/img][u][/u]!! Please remember, however, that the Interhelter only weighs in at 1100lbs, which is spread around a 20' circumference, so the floor loading is nothing. We won't be going big inside with interior construction. It's Chugach coastal climate at 400' elevation. I'm sure 10 - 15' is possible, but the dome won't hold snow, and the minimal remaining deck area should be plenty strong enough to hold whatever snow load could pile up along the edges of the dome. It's not like we're building with 2 x 4s and 4 x 4s....

Jack

|

|

Just

Member

|

# Posted: 12 Mar 2012 08:30 - Edited by: Just

Reply

I like the threaded rod conection idea then the rocks and plastic.the rest sounds right on .

|

|

akparajack

Member

|

# Posted: 12 Mar 2012 15:26

Reply

I saw on another thread the mention of earthquakes, and then geeze I guess you can't win! The culvert pipe stacked with rocks sounds doable to us but ultimately they're just sitting there. Granted they would have substantial weight and mass, and have the all the rest of the foundation and structure sitting on it..... still, it makes us think that we should get at least some of the posts tied in somehow... as difficult as it might be...

|

|

soundandfurycabin

Member

|

# Posted: 13 Mar 2012 02:18

Reply

A hammer drill won't drill rock. For that you need a rotary hammer. Instead of epoxy I suggest using an acrylic adhesive like Redhead A7. Less expensive than epoxy and a bit easier to work with.

|

|

Icebear

Member

|

# Posted: 13 Mar 2012 04:02

Reply

Do you have room to put a post in the middle of the culvert before the packing material goes down? Then you are essentially building a standard style of foundation but using rock and sand to support the lateral forces on the post. I'd be putting some big rocks at the bottom and big rocks at the top of the culvert and use the smaller stuff rammed into the middle.

It might also be nice if you can seal off the top of the culvert to make it water proof. I'd be worried about rain filling the culvert just before winter and the possibility of it being solid ice through winter. Who know's what that will do to the stability

My personal preference would probably be to use the helo for carrying tools. Take in a petrol post hole borer and chainsaw. cut your posts on site - doesn't matter how good they look; and just set them as deep as you can with dirt pounded back into the holes. Do as many posts as you can in the time you have.

|

|

akparajack

Member

|

# Posted: 13 Mar 2012 05:40

Reply

It's an interesting dilemma as ultimately the dome is a temporary structure, and we really have to decide how much time, effort, and expense we want to invest in something meant to just get us through a few years. The dome will last for decades and will be great to have on the property but its not the end game by any stretch. Once we're in there then we'll be free to start working with local materials and planning a more permanent structure.

It's too bad the advanced technology of the dome couldn't some how be matched with an equally novel foundation solution. It's seems crazy to have such a simple structure solution matched with such a challenging foundation/post/beam/joist/deck requirement. I know it will work out, it's just that having never done it along with the logistical challenges really keeps us guessing. "Just stack rock and call it good" is sounding better all the time!

It's been many years since we've been in there, so a fact finding trip to determine just what were up against for the foundation is becoming more important....Who knows, maybe well find some nice ground to work with but I guarantee it won't be dirt that you could just auger down thru for a conventional sono tube or some type of buried pt post. I'm pretty certain whatever we end up with will be mostly on grade or anchored or set on rock....

|

|

akparajack

Member

|

# Posted: 17 Mar 2012 13:08

Reply

Given that we're supporting an 1100 lb dome with minimal snow load, and a reasonable amount of added furnishings inside, what would be the better choice for our 10' span:

2 x 10 x 12 on 24" centers with 3/4" plywood for decking, or 2 x 8 x 12 on 16" centers with 3/4" plywood decking?

Plz don't answer with neither :>

|

|

Just

Member

|

# Posted: 17 Mar 2012 21:22

Reply

my choice would be 2 x 8 's with 5\8 T&G plywood subfloor .

|

|

akparajack

Member

|

# Posted: 17 Mar 2012 21:53

Reply

<<my choice would be 2 x 8 's with 5\8 T&G plywood subfloor .

So far I havent seen any PT T&G plywood. All the treated stuff I've seen so far is normal edged...

|

|

Just

Member

|

# Posted: 17 Mar 2012 22:34

Reply

you are correct gess i missed the pt part .not sure if you need it though , long as that dome does'nt leak and u go with the pt decking outside should last a lifetime you could go with 1 x 6 radius edge pt. decking save some more weight [ works well on 16 in. centers ]

|

|

Anotherflyer

Member

|

# Posted: 14 Sep 2017 01:59

Reply

akparajack

Did you ever get your platform and subsequent cabin built? Not only does it sound interesting, but I am building there too. Maybe we are even neighbors. I would love to chat.

Eric

|

|

|